Two-way stretching mold for polytetrafluoroethylene hollow fibrous membrane

A technology of polytetrafluoroethylene and biaxial stretching, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as hollow fiber collapse and hollow fiber rupture, and achieve small pore size and high porosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

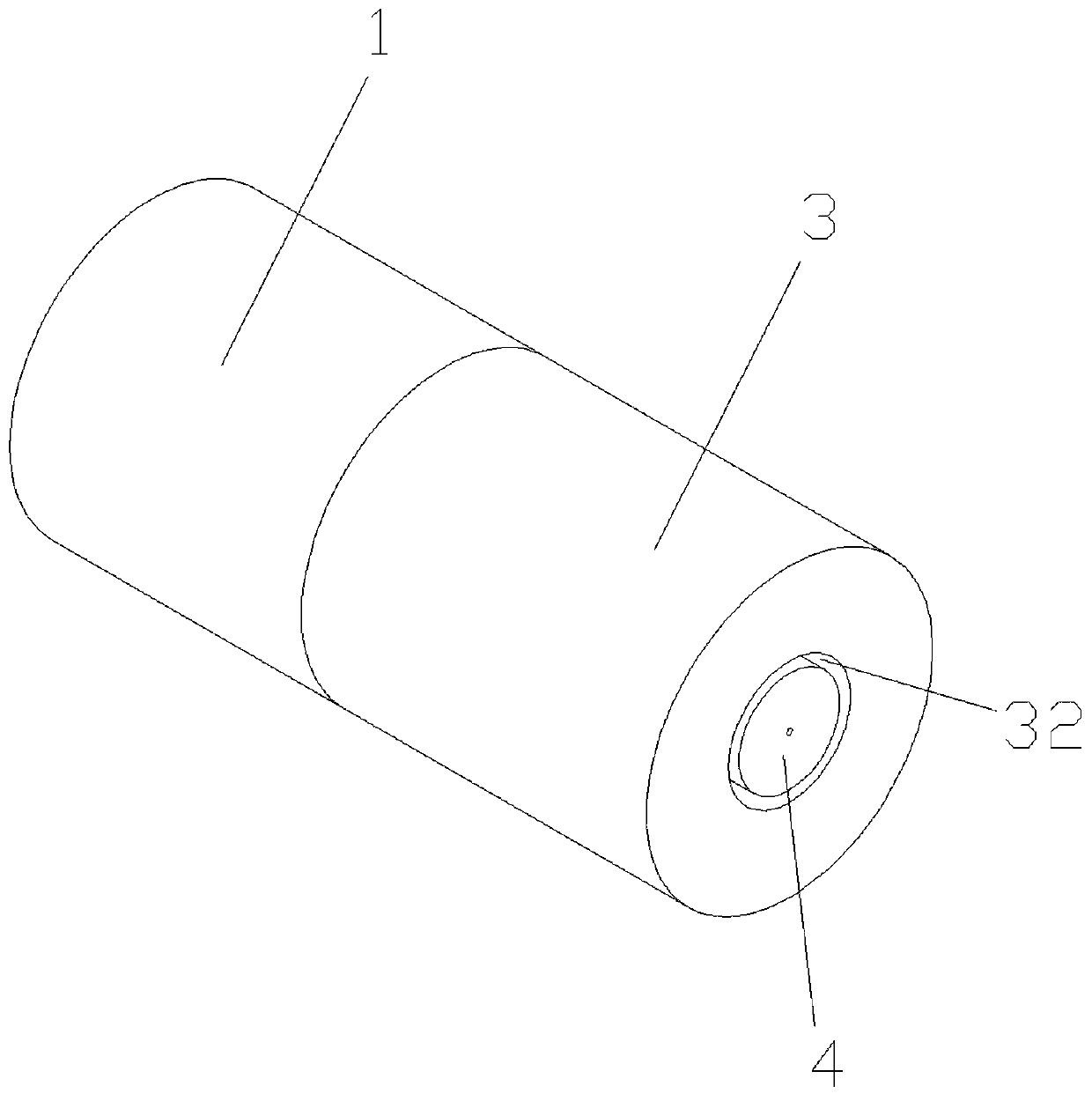

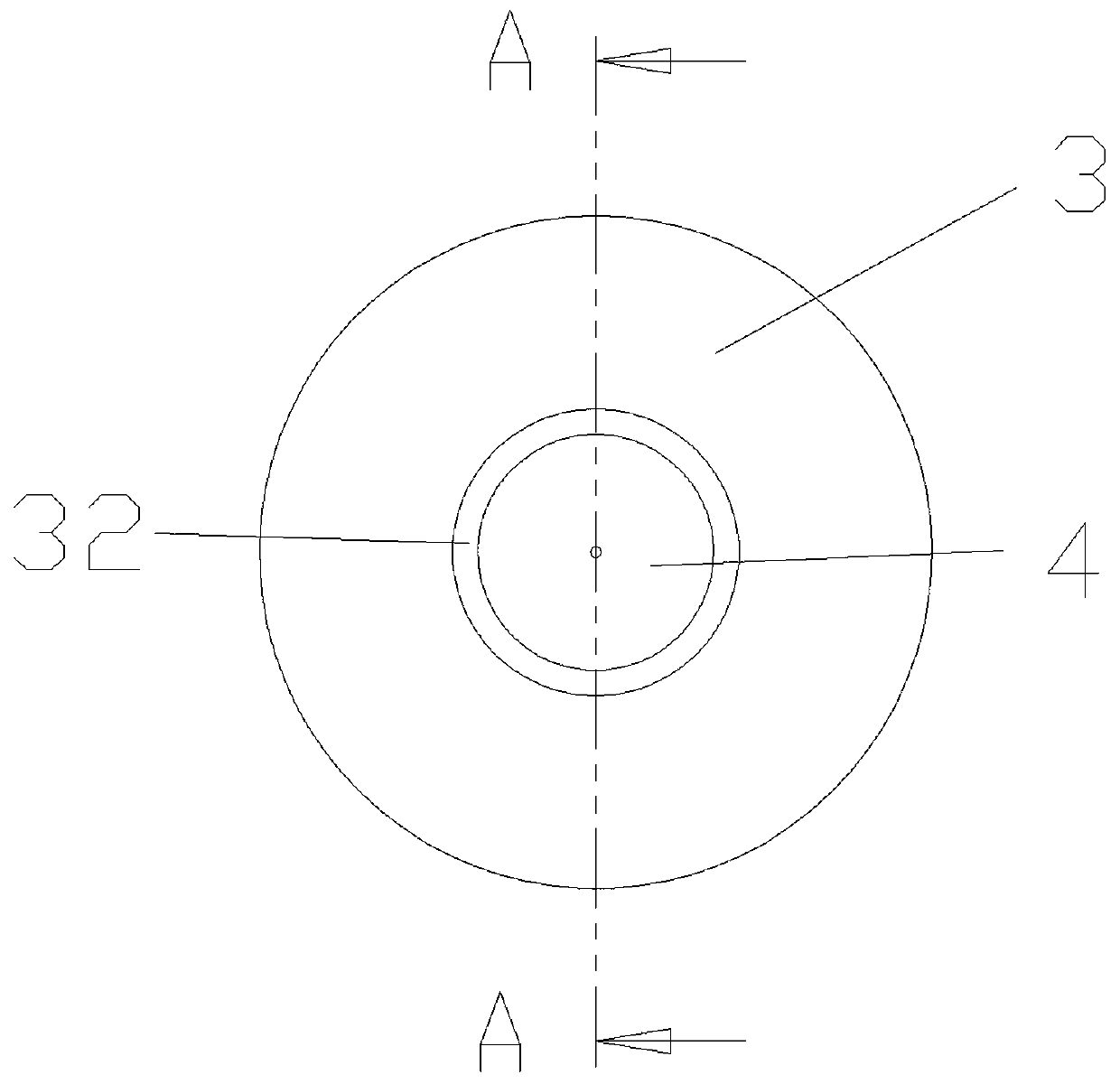

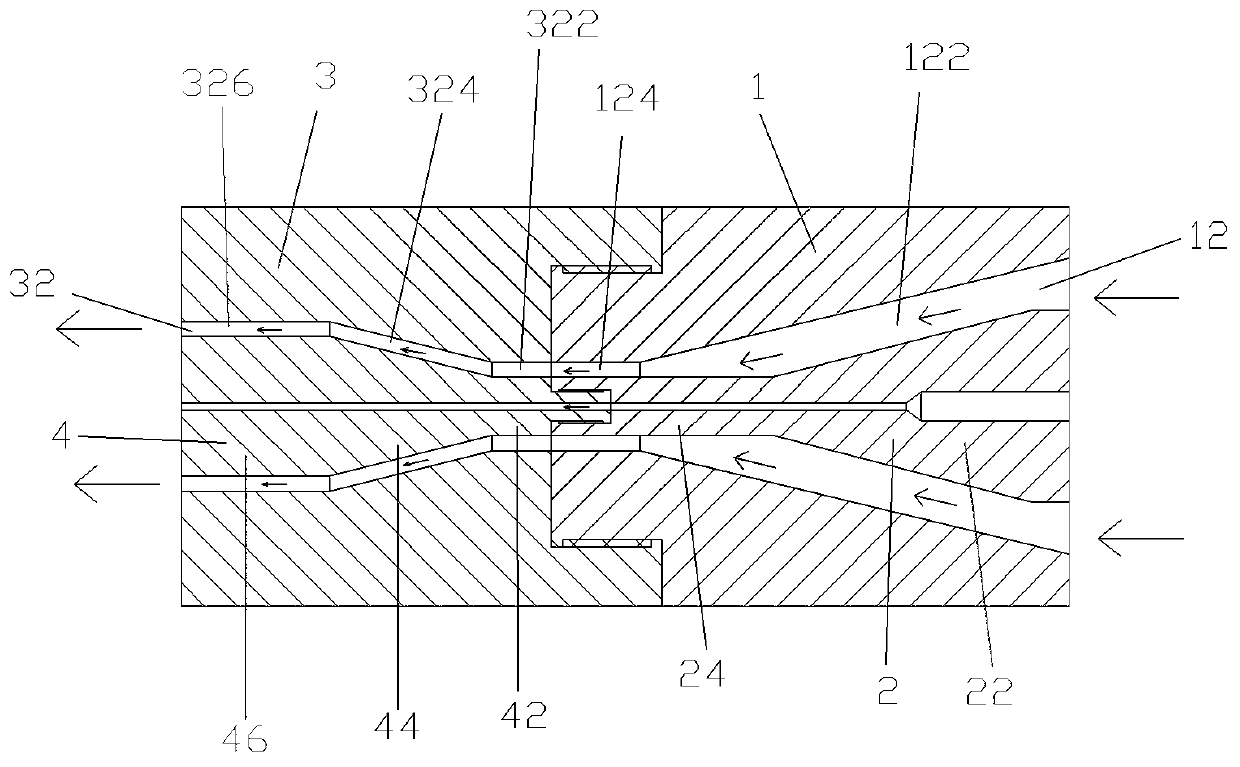

[0046] see Figure 1 to Figure 3 , a polytetrafluoroethylene hollow fiber membrane biaxial stretching mold, comprising an outer mold 1, a core mold 2, an expansion outer mold 3, and an expansion core mold 4.

[0047] The outer mold 1 and the core mold 2 are installed and fixed at the outlet end of the pushing equipment (not shown).

[0048] The inside of the outer mold 1 is dug to be provided with the outer mold through hole 12 that runs through front and back.

[0049] The outer mold through hole 12 includes an outer mold through hole rear section 122 and an outer mold through hole front section 124 that communicate with each other from back to front.

[0050] The rear section 122 of the through hole of the outer mold is in the shape of a truncated cone, and its diameter gradually becomes smaller from the back to the front.

[0051] The front section 124 of the through hole of the outer mold is cylindrical and has a constant diameter.

[0052] The core mold 2 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com