Continuous banburying and calendaring production equipment and technology for rich mineral paper

A production equipment and technology of stone paper, applied in the field of stone paper continuous mixing and calendering production equipment and technology, can solve the problems of inconvenient control of the thickness and quality of the calender, and achieve the effect of reducing weight, improving quality, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

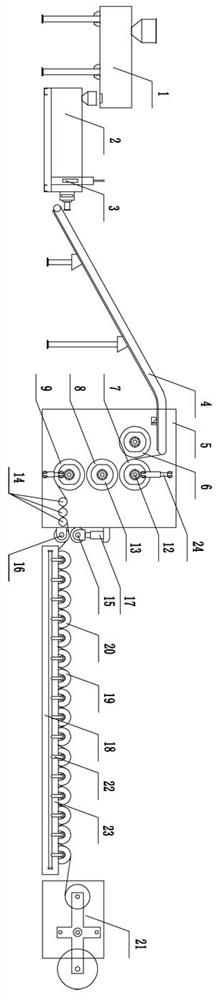

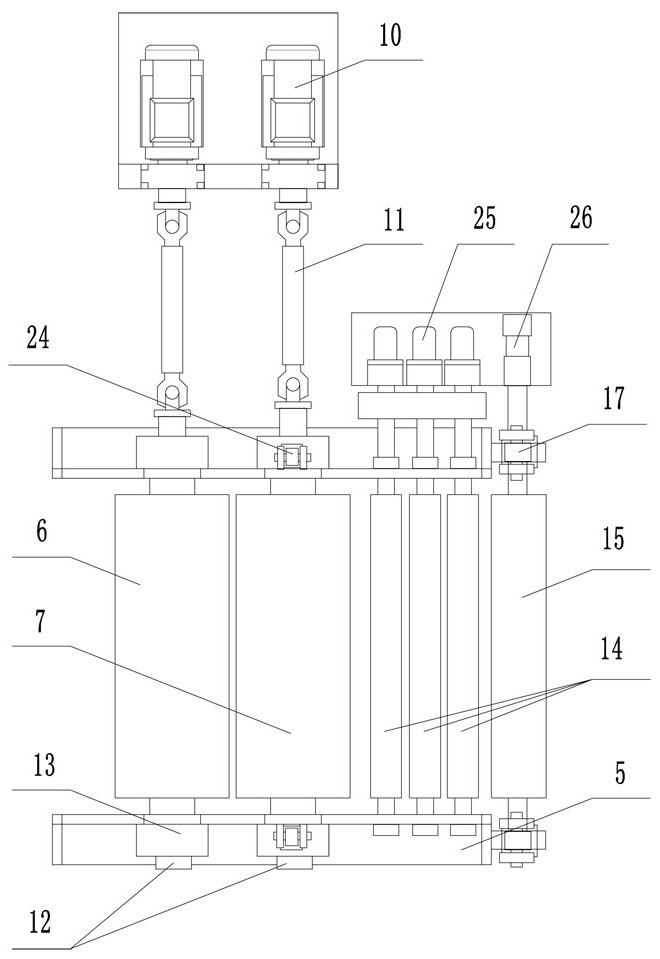

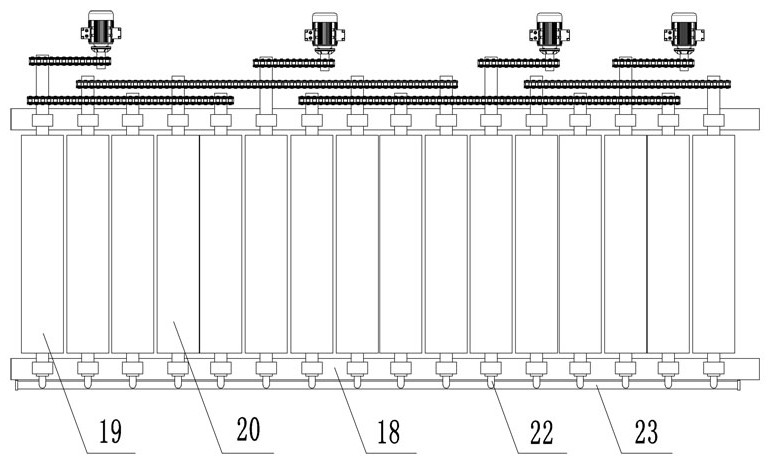

[0036] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

[0037] Such as Figure 1~Figure 3 As shown, a continuous mixing and calendering production equipment for stone paper, including a continuous mixer unit for mixing stone paper raw materials, an extrusion unit for extruding stone paper raw materials, and an impurity filter Screen changer 3, conveyor belt 4 for transporting stone paper, calendering unit for pressing stone paper, embossing unit for printing and decoration, cooling and setting unit for cooling and setting of stone paper, and winding of stone paper Baled winding unit;

[0038] The continuous mixer unit and the extruder unit are connected, the screen changer 3 is arranged in the extruder unit, the extruder unit and the calender unit are communicated through the conveyor belt 4, and the calender unit is also connected A lead-away roller set is provided, and the calendering unit and the emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com