Ink jet head and control method thereof

A control method and technology of inkjet head, which are applied in the directions of inking device, printing, printing device, etc., can solve the problems of uneven speed or volume of ink droplets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

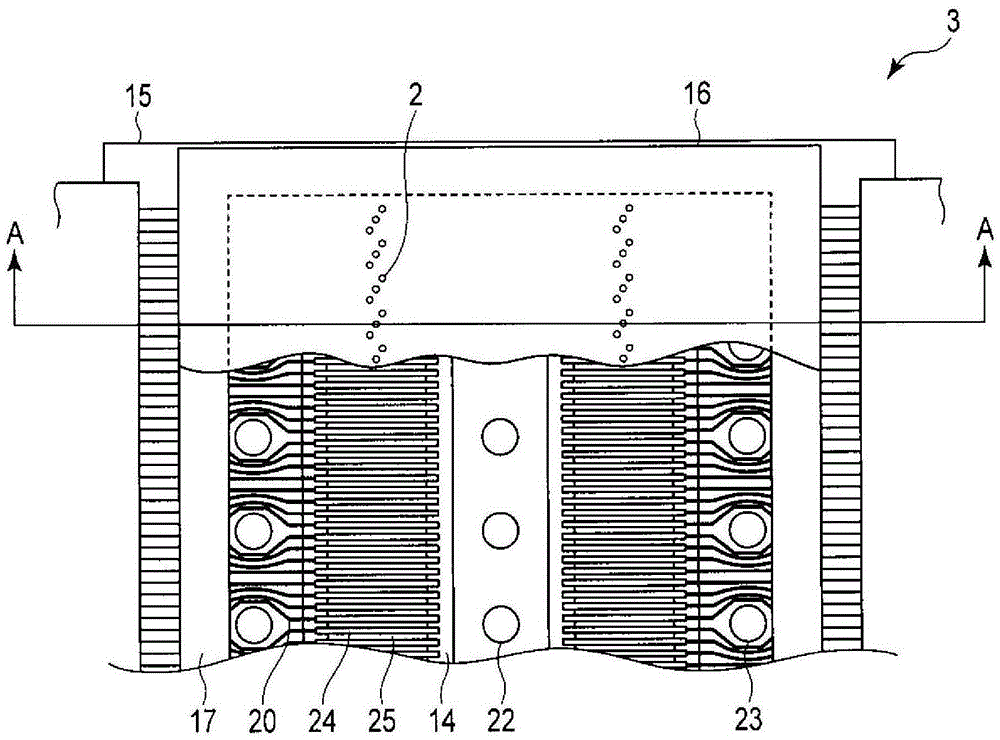

[0023] First, a first embodiment will be described.

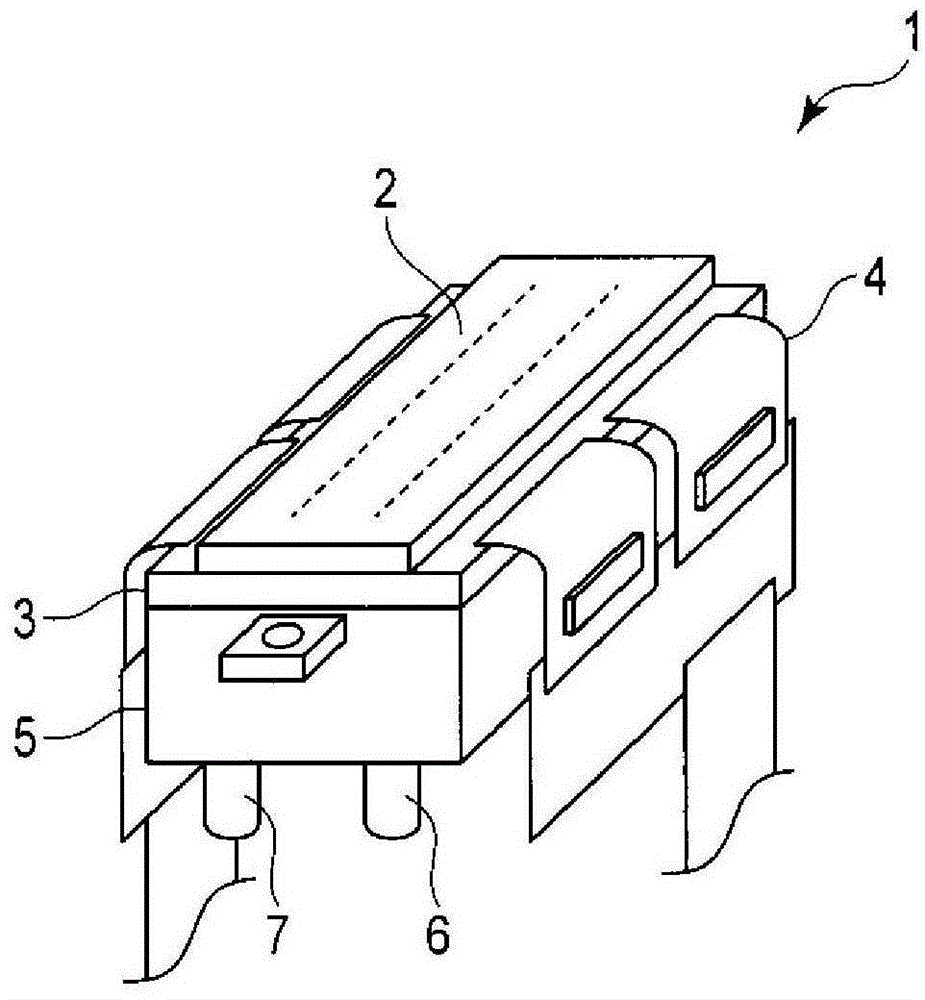

[0024] figure 1 It is a perspective view of the inkjet head 1 of the inkjet head recording device according to the first embodiment.

[0025] The inkjet head 1 includes: a head substrate 3 having nozzles 2 that eject ink; a driver IC 4 that generates drive signals; and a manifold 5 having ink supply ports 6 and ink discharge ports 7 .

[0026] The inkjet head 1 discharges the ink supplied from the ink supply port 6 from the nozzle 2 based on a drive signal generated by the drive circuit 4 . Among the inks flowing in from the ink supply port 6 , the ink not discharged from the nozzle 2 is discharged from the ink discharge port 7 .

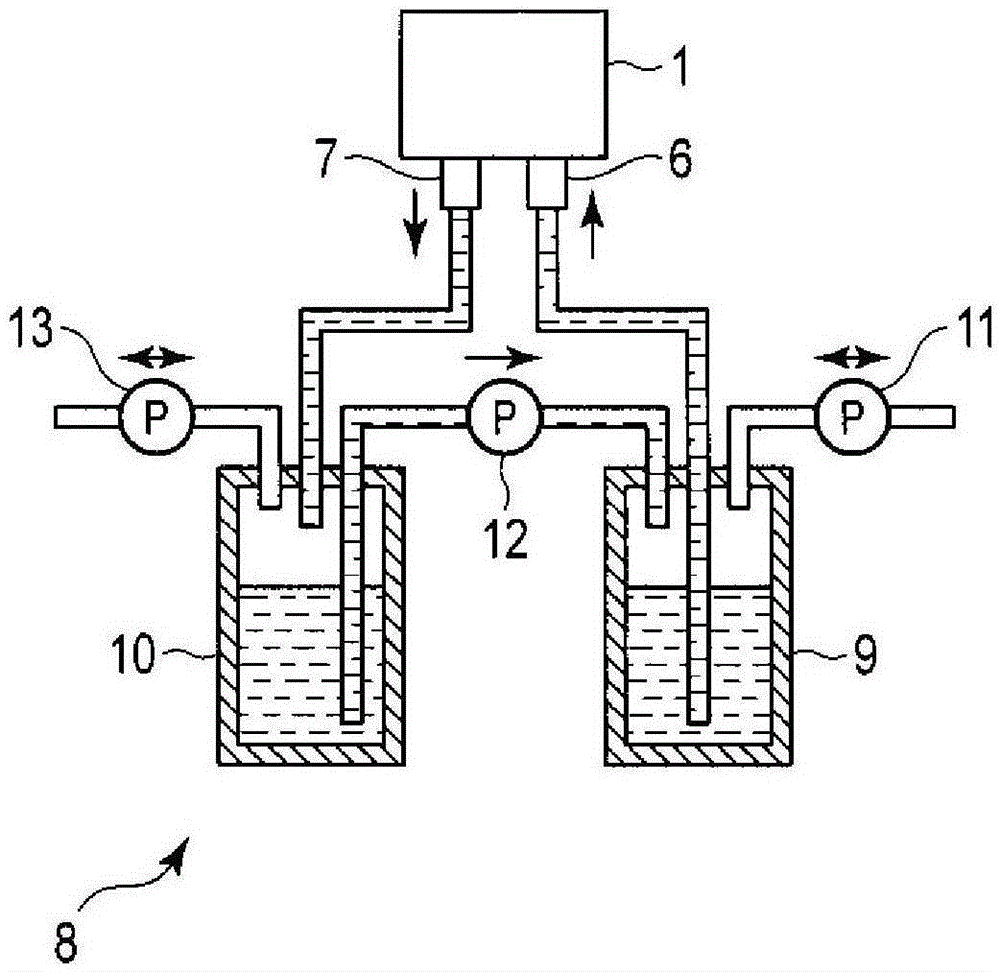

[0027] figure 2 It is a schematic diagram of the ink supply device 8 used in the inkjet head recording device of the first embodiment. The ink supply device 8 is composed of a supply-side ink cartridge 9, a discharge-side ink cartridge 10, a supply-side pressure regulating pump 11, a transfe...

no. 2 approach

[0058] Next, a second embodiment will be described.

[0059] exist Figure 7(a) , 7(b) In the above, the situation of controlling by the driving signal of the two-stage voltage level is described, and it can also be as follows Figure 9(a) , 9(b) The drive signals shown are controlled by three-stage voltage levels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com