Full automatic control lime shaft kiln production line

A technology of production line and vertical kiln, which is applied in the field of fully automatic control of lime vertical kiln production line, can solve the problems of insufficient sealing effect and insufficient stability of vertical kiln material surface drop, achieve convenient raw material mixing ratio, reduce topping and sliding phenomenon, The effect of adjusting the mixing ratio of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

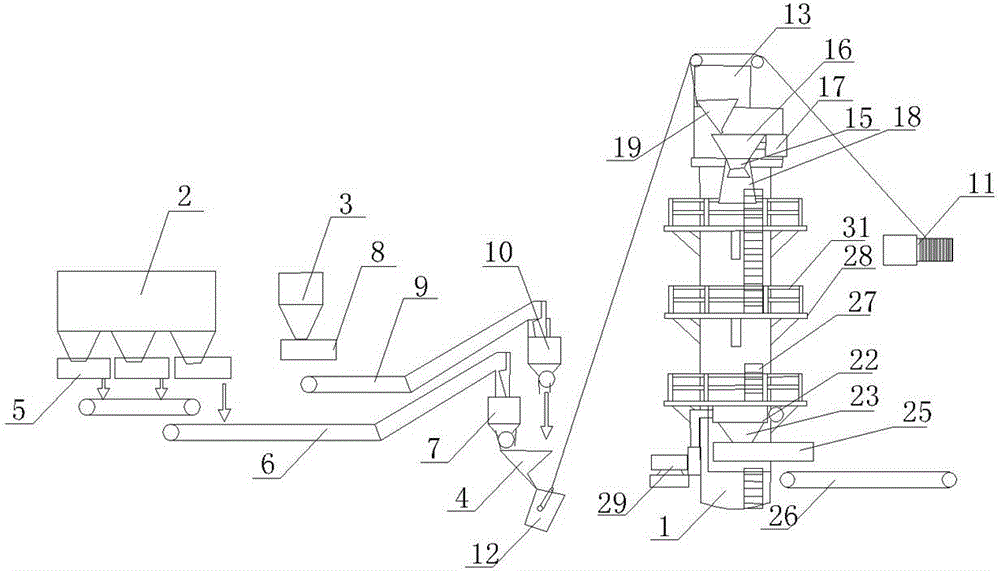

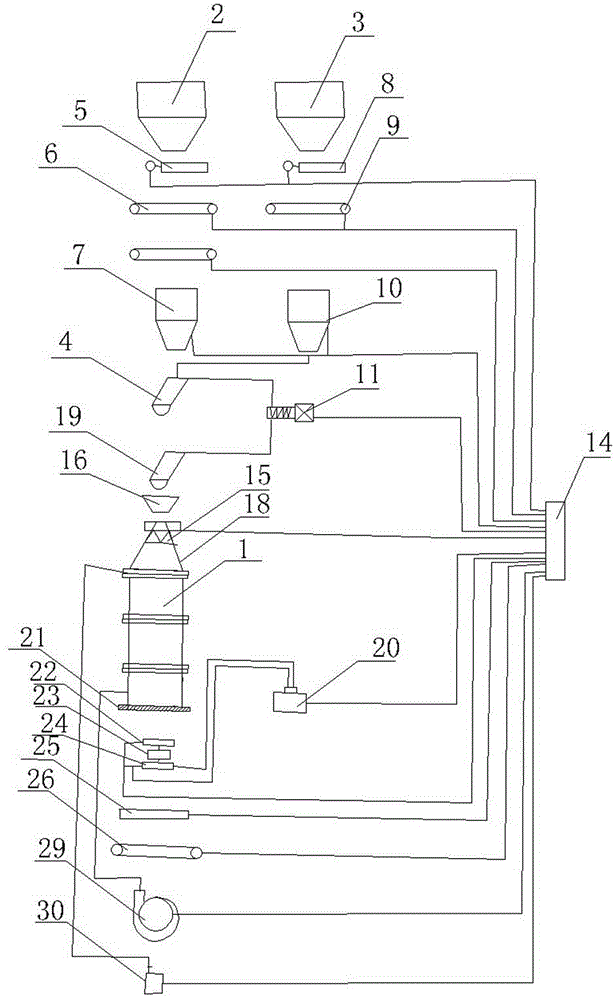

[0033] Such as figure 1 and 2As shown, a fully automatic lime shaft kiln production line includes a shaft kiln, a feeding system, a material distribution system and an ash discharging system. The feeding system includes a mixing hopper 4, a limestone bin 2, and a first belt conveyor 6 for transporting limestone. , the coal bunker 3 and the second belt conveyor 9 for transporting coal, the distribution system includes a distributor arranged on the top of the shaft kiln 1, and the ash discharge system includes a cooling device arranged in the shaft kiln 1 and a cooling device arranged at the bottom of the shaft kiln 1 Four ash removal machines 22, a first vibrating feeder 5 is provided at the bottom outlet of the limestone bin 2, a second vibrating feeder 8 is provided at the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com