A method for erecting juxtaposed box girders in tunnels

An in-tunnel and box girder technology, applied in the erection/assembly of bridges, bridges, bridge construction, etc., can solve the problems of complex methods, difficult operation, high cost, and achieve the effect of high stability factor, reducing construction difficulty and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

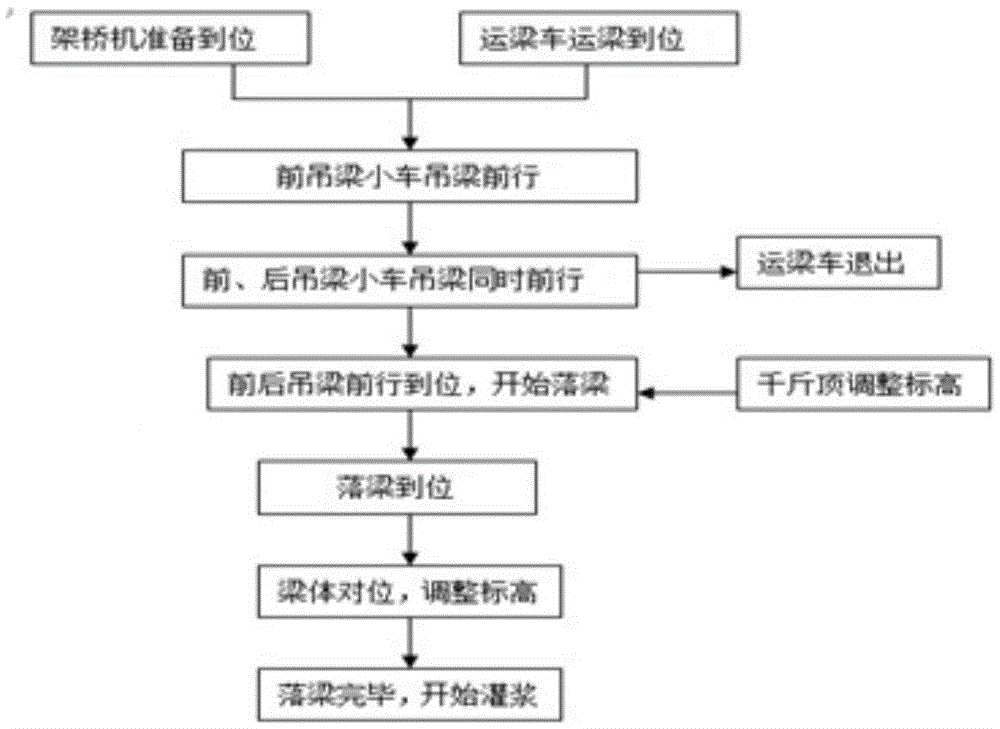

[0038] Such as figure 1 Shown is the flow chart of the method for erecting and arranging box girders in the tunnel 03 of the present invention. This specific embodiment adopts the TLC450 type bridge erecting machine 1, including the following steps:

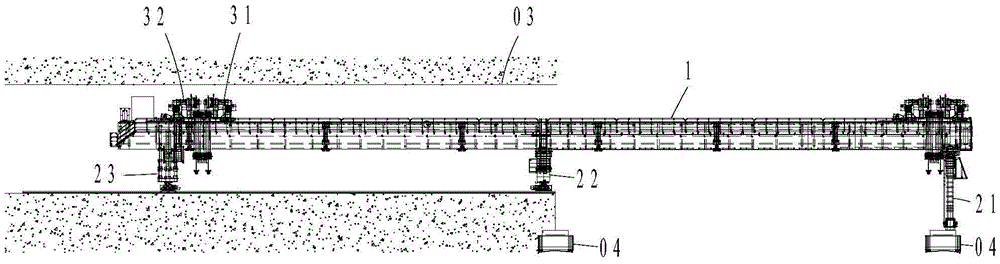

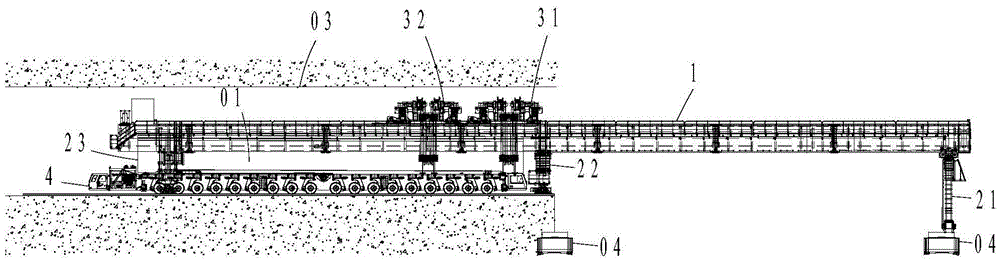

[0039] Step 1, the bridge erecting machine 1 passes through the tunnel 03; figure 2 As shown, the girder truck carries two brackets into the belly of the bridge erecting machine 1, and the girder trolley travels to the end of the main beam of the bridge erecting machine 1 as a counterweight; the beam truck is raised to the middle posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com