Liquid column jet type stack gas desulfurization

A jet type, desulfurization tower technology, applied in the field of flue gas purification and desulfurization, can solve the problems of difficult installation of jet branch pipe brackets, small slurry distribution area, affecting desulfurization efficiency, etc., to reduce erection difficulty, distribute evenly, and improve desulfurization efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

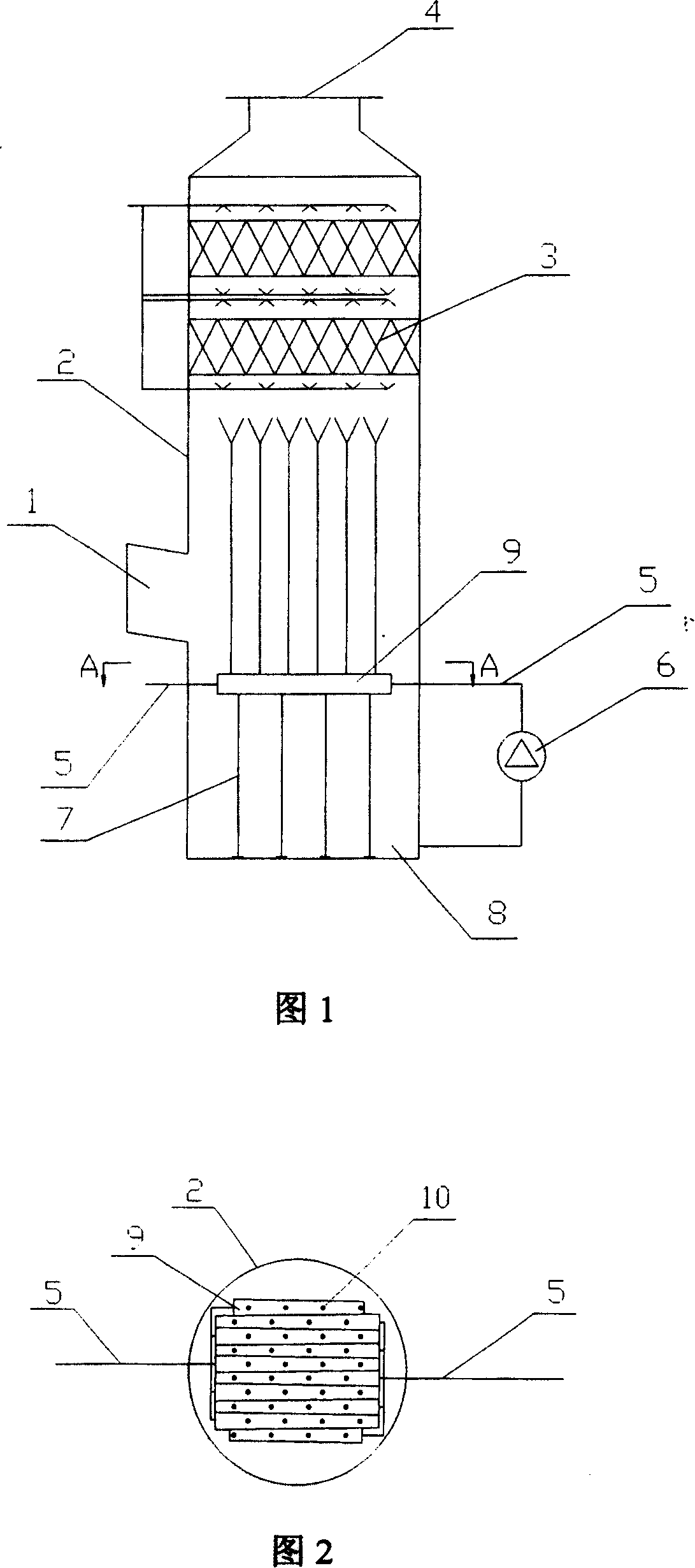

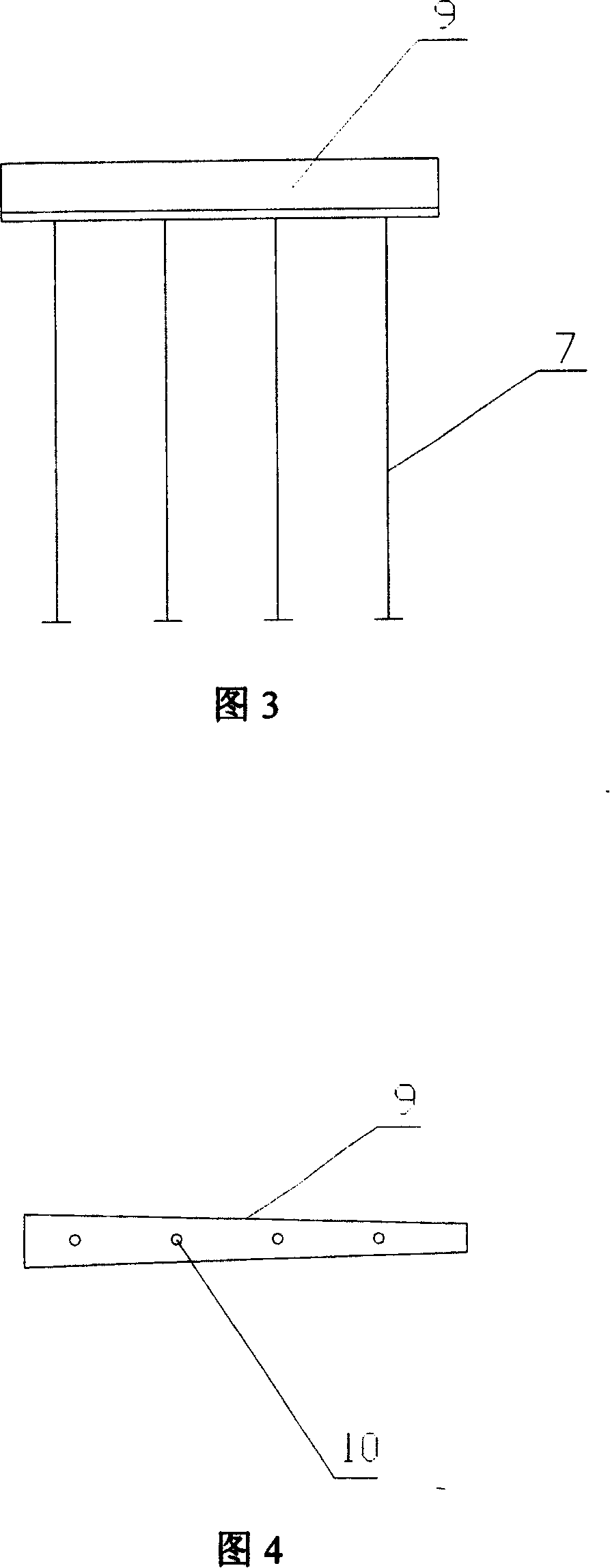

[0015] Referring to Figures 1 to 4, the present invention includes a tower body 2, a flue gas inlet 1 connected to the middle of the tower body 2, a flue gas outlet 4 connected to the top of the tower body 2, and a double-layer defogger placed in the upper part of the tower body 2 3, a slurry collector 8 placed at the bottom of the tower body 2, a slurry circulation pump 6 connected to the slurry collector 8, and an injection pipe connected to the outlet of the slurry circulation pump 6 and placed below the flue gas inlet 1. The flue gas inlet 1 pipe and the horizontal cross-section of the tower body 2 are inclined upward at an angle of 5-10°. The injection pipe is composed of a plurality of square tubes 9 with evenly variable diameters from large to small and bidirectionally staggered. The upper and lower end surfaces of each tube 9 are trapezoidal, and the two sides of each tube 9 are rectangular. The large-diameter ends of the pipes 9 on all sides are connected in parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com