Drainage sluice structure

A drainage gate and ram technology, which is applied in water conservancy projects, artificial waterways, sea area engineering, etc., can solve the problems of difficult restoration and cleaning, water leakage of gates, and damage to objects, etc., and achieve simple gate structure, reduce sediment deposition, and protect from being damaged The effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

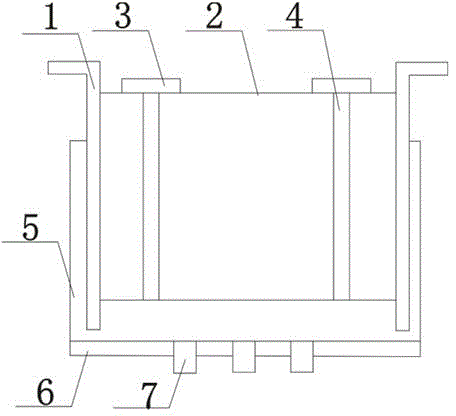

[0019] The present invention will now be described in further detail with reference to the accompanying drawings. These drawings are all simplified schematic diagrams, and only illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0020] like figure 1 The preferred embodiment of the structure of the drainage gate of the present invention is shown, including a gate 1, the gate 1 is an inverted L-shaped structure, and there are two gates 1, a gate 2 is installed between the two gates 1, and the gate 2 is connected to the gate. The plates 1 are connected by a rotating shaft. The outside of the gate 1 is provided with a side baffle 5. The side baffle 5 and the gate 1 are fixedly connected. The side baffle 5 is composed of two vertical baffles and one horizontal baffle. , the vertical baffle and the horizontal baffle are integrally connected, the lower surface of the horizontal baffle is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com