Silicone oil damper of diesel engine crankshaft

A diesel engine and shock absorber technology, which is applied in the direction of shock absorbers, liquid shock absorbers, shock absorbers, etc., can solve the problems that the torsional vibration of the engine crankshaft cannot be effectively reduced, and the installation space of the diesel engine is limited, etc., and achieve compact structure, The effect of reducing the number of parts and reducing production management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

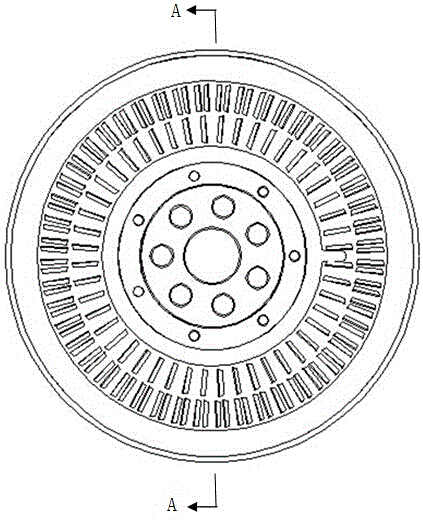

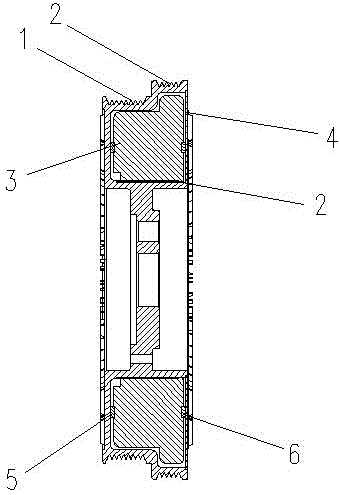

[0015] A diesel engine crankshaft silicon oil shock absorber, comprising a T-shaped housing, a T-shaped inertia block 3, a cover plate 4, a cooling fin 5 and a bearing strip 4, and the cooling fin 5 and the bearing strip 4 are fixedly connected to the silicon oil shock absorber T T-shaped inertia block 3 is installed in the T-shaped casing, silicone oil is injected into the gap between the T-shaped inertia block and the T-shaped casing, and the T-shaped inertia block 3, bearing belt 4, and silicone oil are sealed in the silicone oil vibration damping In the T-shaped housing of the device. The outer edge of the T-shaped shell is serrated. The T-shaped housing is composed of a first ring body 1 and a second ring body 2, the diameter of the second ring body 2 is larger than that of the first ring body 1, and the first ring body 1 and the second ring body 2 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com