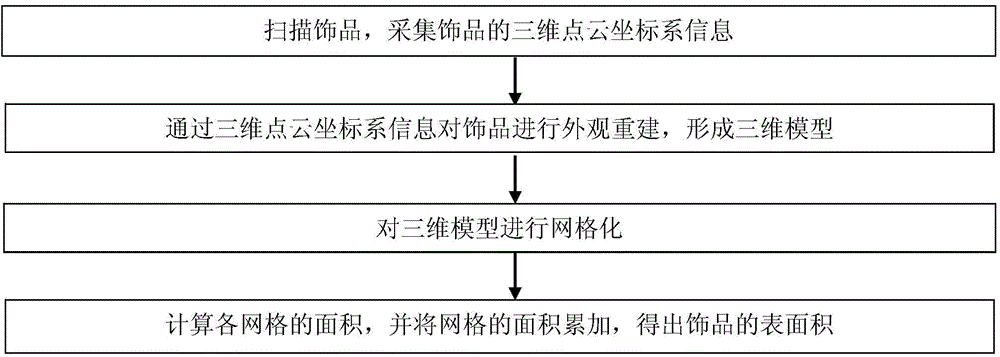

Ornament surface area rapid detection method and system based on image analysis technique

An image analysis and detection method technology, applied in measuring devices, instruments, and optical devices, etc., can solve the problems of low precision, poor accuracy, and high cost, and achieve a faster detection process, reduced workload, and high accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

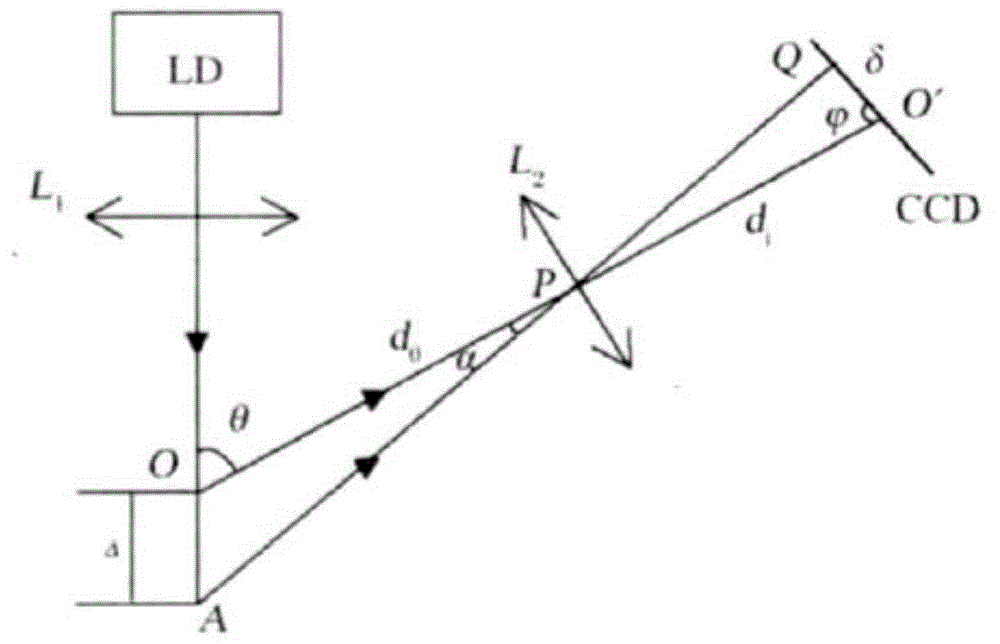

Method used

Image

Examples

Embodiment 1

[0095] This embodiment selects the Creaform 3D Scan portable scanner, which has an accuracy of 0.1 mm and a measurement speed of 550,000 times / s. It can quickly and accurately reproduce the three-dimensional information of the object. It has the characteristics of lifelikeness and reproducibility. It can eliminate the shortcomings of traditional structured light imaging such as limited physical size, complicated acquisition, and high cost.

[0096] In order to illustrate the accuracy of the present invention's calculation, select a ring with a regular shape (such as Figure 6a and Figure 6b Shown) sample, utilize the present invention and traditional manual area measurement method to measure and calculate respectively, test data is compared.

[0097] Table 1: Manually measured ring size data (unit: mm)

[0098] diameter

width

16

3

[0099] According to the data in Table 1, the immersion area of the ring sample is calculated as:

[0100] S...

Embodiment 2

[0109] In this embodiment, the surface area of the more complicated necklace sample is detected, and the same calculation process as in Example 1 is adopted. The physical figure of the necklace sample is as follows Figure 7 shown.

[0110] Table 2: Manually measured life-size data (unit: mm)

[0111] necklace length

Necklace body width

buckle diameter

buckle thickness

nameplate length

Nameplate width

40

1

5

1

5

3

[0112] Necklace samples are more complicated than ring samples, and need to be decomposed to calculate the area. According to the shape of the necklace sample, it is roughly divided into three parts: the necklace body, which is approximately rectangular; the buckle, which is approximately circular; the nameplate, which is approximately rectangular. According to the manual test data in Table 2, we get:

[0113] 1. Necklace body area:

[0114] S 1 =2×(40×1)=80mm 2

[0115] 2. Buckle area:

[011...

Embodiment 3

[0125] In this embodiment, badge samples are selected, and the calculation process is the same as that in Example 1. Since the shape of the badge is irregular and the front surface has protrusions, the method of calculating the area by manual division is not only time-consuming and laborious, but also difficult to obtain accurate data. Using the present invention to measure and calculate the surface area, first use the Creaform 3D Scan portable scanner to align the simulated ornament. After a comprehensive scan, the effect after three-dimensional reconstruction is as follows: Figure 8a to Figure 8c shown.

[0126] Utilize the area calculation module of the present invention to measure and calculate the surface area, and the automatic calculation obtains that the surface area is 1,364.57 millimeters 2 , took 1 minute and 45 seconds, and successfully realized the 3D reconstruction and automatic calculation of the surface area of complex shape ornaments.

[0127] In this exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com