Mini-type circuit breaker

A technology for miniature circuit breakers and shells, which is applied to circuit breaker parts, circuit breaker contacts, circuits, etc., and can solve the problem of severe damage of joints and connecting parts, poor dielectric strength of circuit breakers, and problems with moving contact pieces. Problems such as advanced molding process, to achieve the effect of low production process requirements, good stability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In the following, the present invention will be further described by using the following embodiments in conjunction with the accompanying drawings.

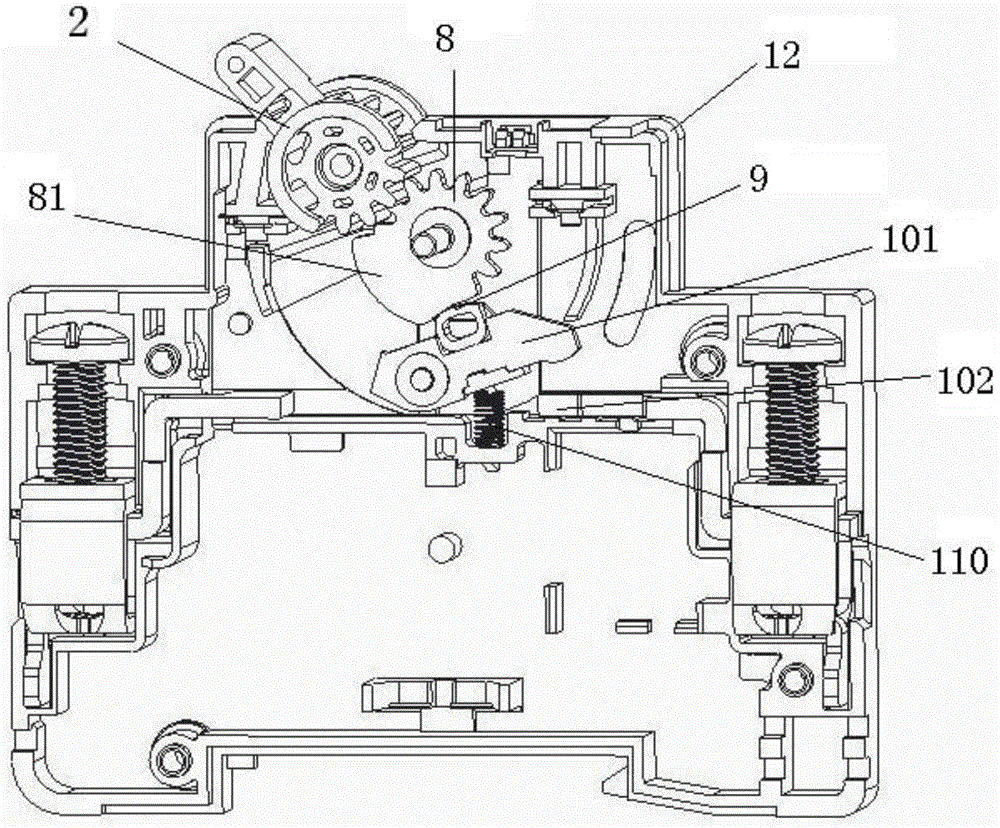

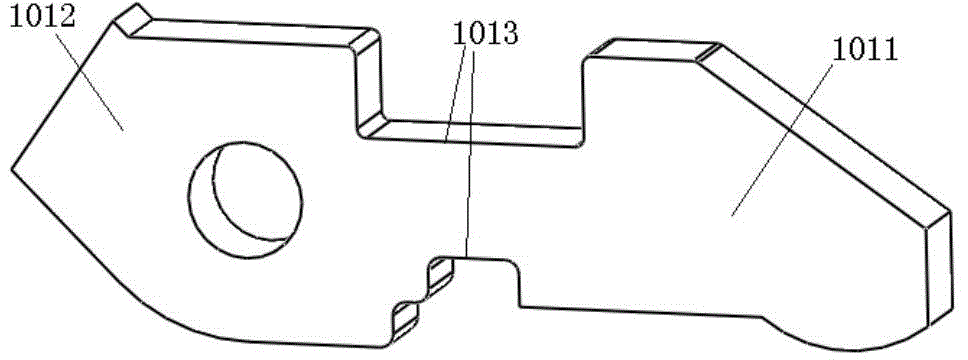

[0067] Such as figure 1 , figure 2 Shown is a specific embodiment of the contact system of the circuit breaker of the present invention,

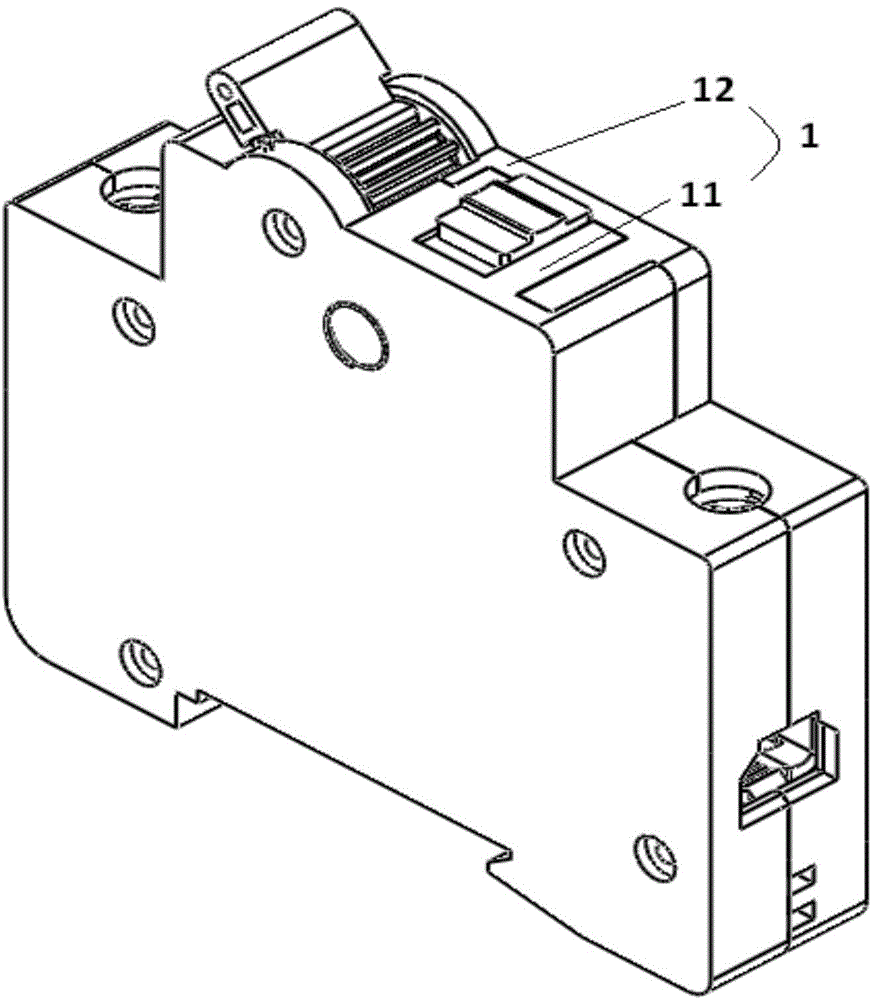

[0068] Such as figure 1 , Figure 17 and Figure 18 Shown is a specific implementation of the miniature circuit breaker of the present invention, the miniature circuit breaker includes a housing 1, and a contact system, a transmission system, a clutch device, a tripping device and a driving motor 170 arranged in the housing 1 , the transmission system includes a first transmission system and a second transmission system that drive each other, the drive motor 170 drives the first transmission system to move, and then drives the second transmission system to move, and the second transmission system drives The contact system operates to make or break the circuit breaker.

[0069] Am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com