Dual-winding single-stage primary feedback LED (Light Emitting Diode) lamp drive circuit

A technology of LED lamp and primary side feedback, applied in the direction of electric lamp circuit layout, electric light source, electrical components, etc., can solve the problems of complex manufacturing process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

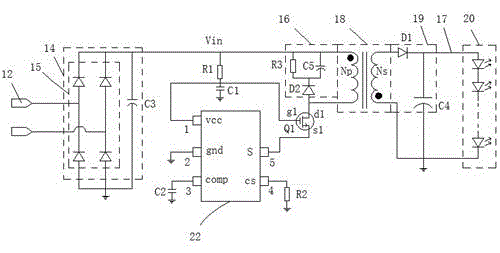

[0023] see figure 2, the present invention provides a double-winding single-stage primary-side feedback LED lamp drive circuit, including: AC input terminal 12, first rectification and filtering module 14, absorption circuit 16, transformer 18, second rectification and filtering module 19, LED lamp The access terminal 17, the first power transistor Q1, the LED driver chip 22, the first resistor R1, the second resistor R2, the first capacitor C1 and the second capacitor C2, the LED driver chip 22 has first to fifth pins 1, 2, 3, 4, 5 (vcc, gnd, comp, cs, S), the first rectification and filtering module 14 is respectively connected to the AC input terminal 12, one end of the first resistor R1, the absorption circuit 16, and the transformer 18 Electrically connected, the other end of the first resistor R1 is respectively electrically connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com