Clothes dryer

A technology for dryers and clothes, applied to other washing machines, household clothes dryers, washing machines with containers, etc., can solve problems such as poor insulation, reduced function of blower and heat exchanger, and reduced performance of lint removal, so as to avoid electric leakage risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0027] First, a first embodiment of the present invention will be described.

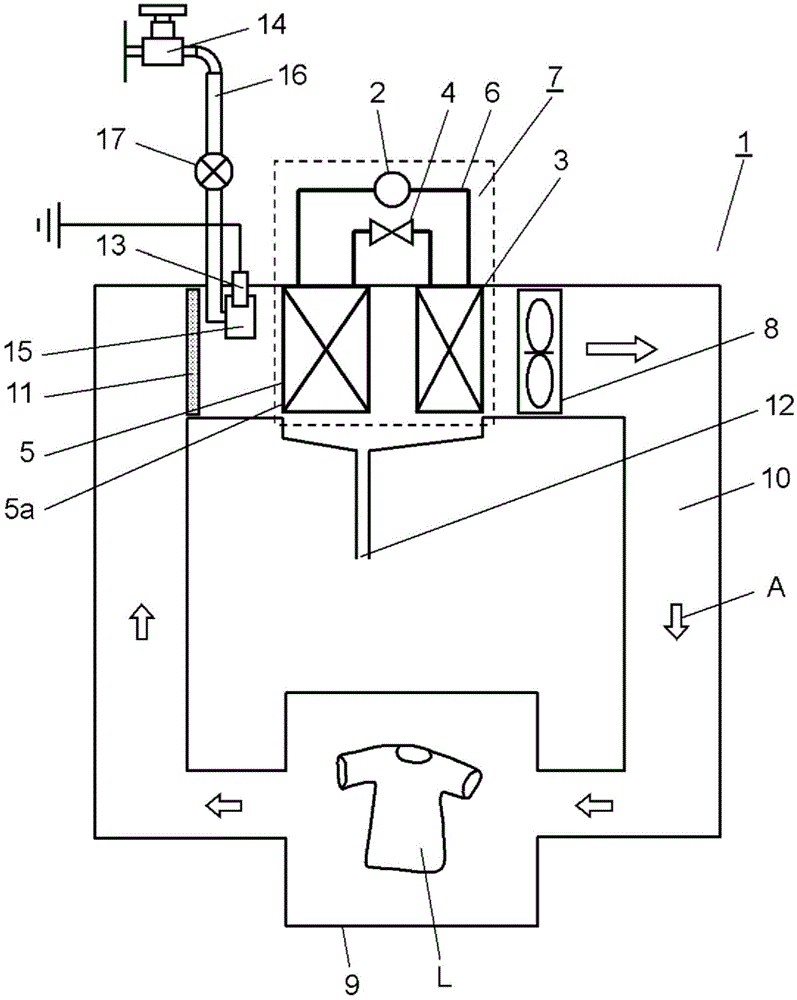

[0028] figure 1 It is a figure which shows the structure of the clothes dryer 1 which concerns on 1st Embodiment of this invention.

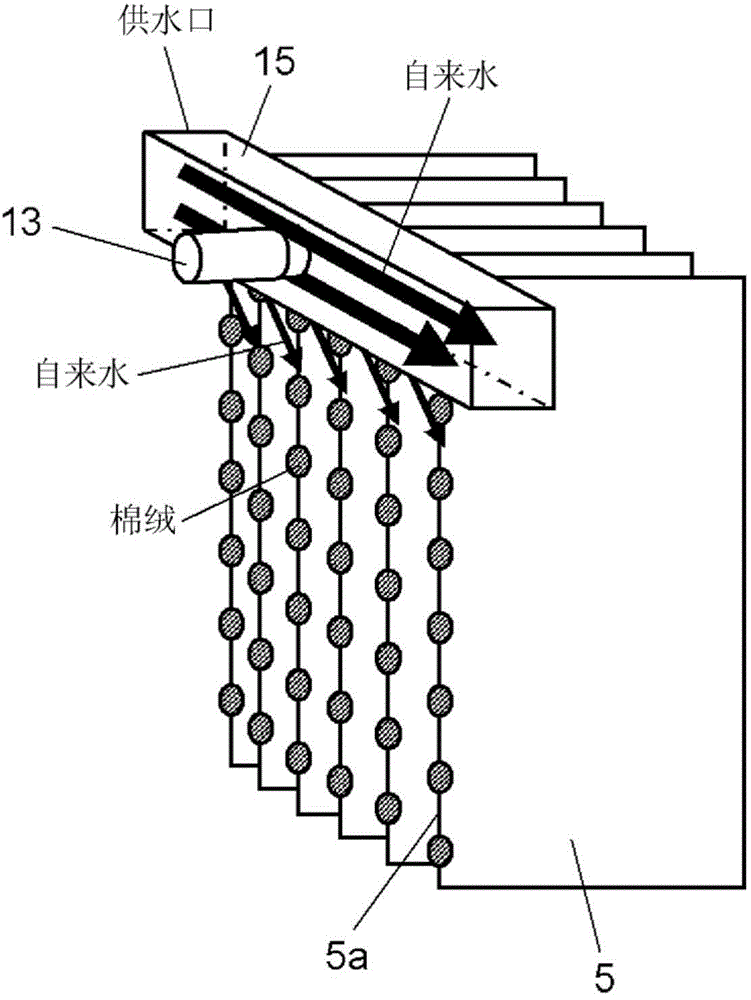

[0029] Clothes dryer 1 has heat pump device 7 for dehumidifying and heating drying air. The heat pump device 7 includes: a compressor 2, which compresses the refrigerant; a condenser 3, which releases the heat of the compressed high-temperature and high-pressure refrigerant; The decompressed capillary tube structure; and the evaporator 5 which uses the decompressed and low-pressure refrigerant to take heat from the surroundings. The heat pump device 7 is obtained by connecting the compressor 2 , the condenser 3 , the throttle unit 4 , and the evaporator 5 through the piping 6 so that the refrigerant circulates.

[0030] The condenser 3 and the evaporator 5 are constituted by metal finned tube heat exchangers. The pipe 6 through which the refrigerant flows is form...

no. 2 approach

[0054] Next, a second embodiment of the present invention will be described.

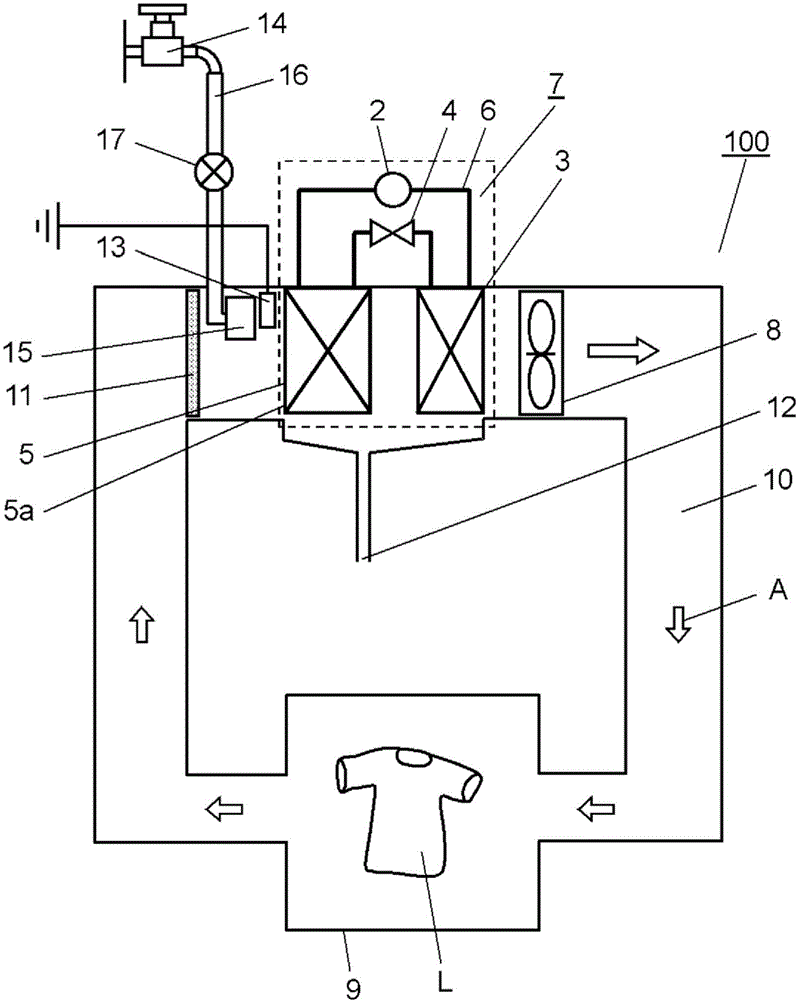

[0055] image 3 It is a figure which shows the structure of the clothes dryer 100 which concerns on the 2nd Embodiment of this invention. in addition, Figure 4 It is a schematic diagram of the vicinity of the evaporator 5 during the lint removal process of the laundry dryer 100 according to the second embodiment of the present invention.

[0056] The difference between the clothes dryer 100 of the present embodiment and the clothes dryer 1 of the first embodiment is the position where the grounding portion 13 is disposed.

[0057] In the clothes dryer 100 of the present embodiment, the ground portion 13 is arranged between the discharge portion 15 and the evaporator 5 . In this way, at least a part of the washing water sprayed from spray portion 15 is sprayed to contact portion 13 . The other configurations are the same as those described in the first embodiment, and the same reference numerals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com