Holder for fastening a tubular component to an add-on structure

一种安装结构、保持件的技术,应用在管元件、管子/管接头/管件、管道支架等方向,能够解决绝缘件挤坏等问题,达到简化装配、准确定位、好构造的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

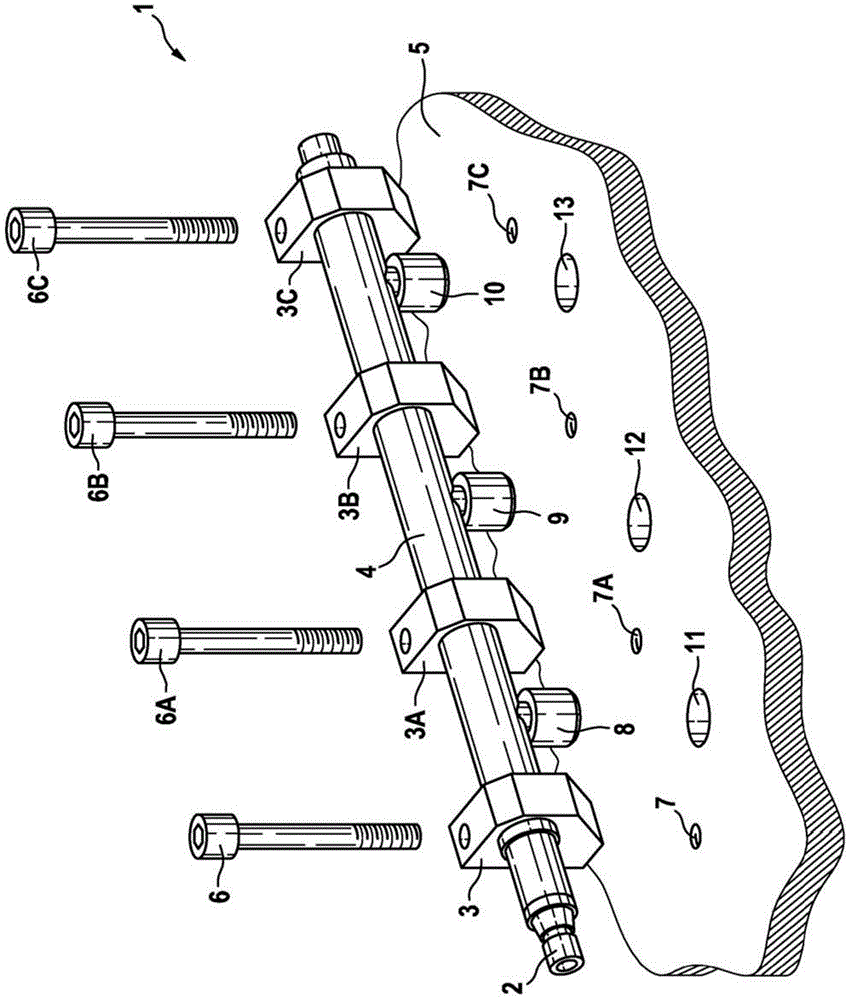

[0023] figure 1 According to a possible configuration, a fuel injection device is shown in a schematic perspective view with a fuel distributor 2 and a plurality of holders 3, 3A, 3B, 3C for connecting the distribution pipe 4 of the fuel distributor 2 It is fastened to a schematically shown additional mounting structure 5 . The holder 3 here includes a threaded rod 6 , by means of which the holder 3 can be screwed onto the additional mounting structure 5 . Correspondingly, the holders 3A, 3B, 3C are provided with further screws 6A, 6B, 6C. The additional mounting structure 5 has suitable threaded holes 7 , 7A, 7B, 7C for this purpose. In this exemplary embodiment, three cups 8 , 9 , 10 are arranged on the distribution pipe 4 , which serve to connect fuel injectors (not shown). These fuel injectors can be partially inserted into the bores 11 , 12 , 13 of the additional mounting structure 5 . In this case the additional mounting structure 5 is the cylinder head 5 of the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com