Large-scale high-efficiency fly maggot culturing equipment and process

A technology of fly maggots and equipment, which is applied in the field of large-scale and efficient fly maggot breeding equipment and technology, can solve the problems of low production efficiency, high labor intensity of workers, cumbersome operating procedures, etc., achieve high degree of automation, realize large-scale and high efficiency The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

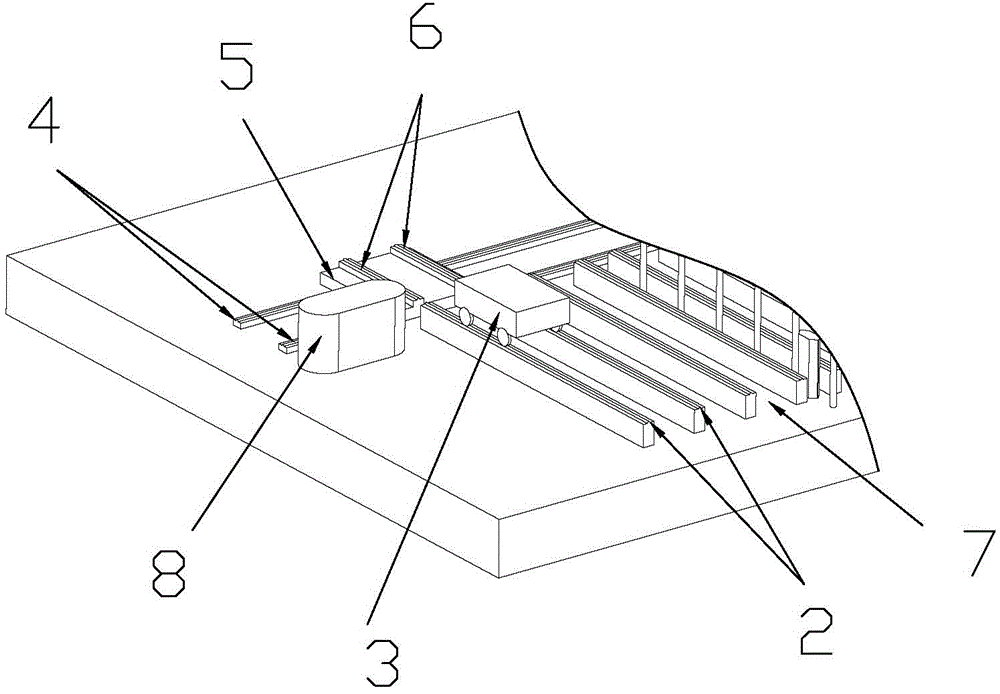

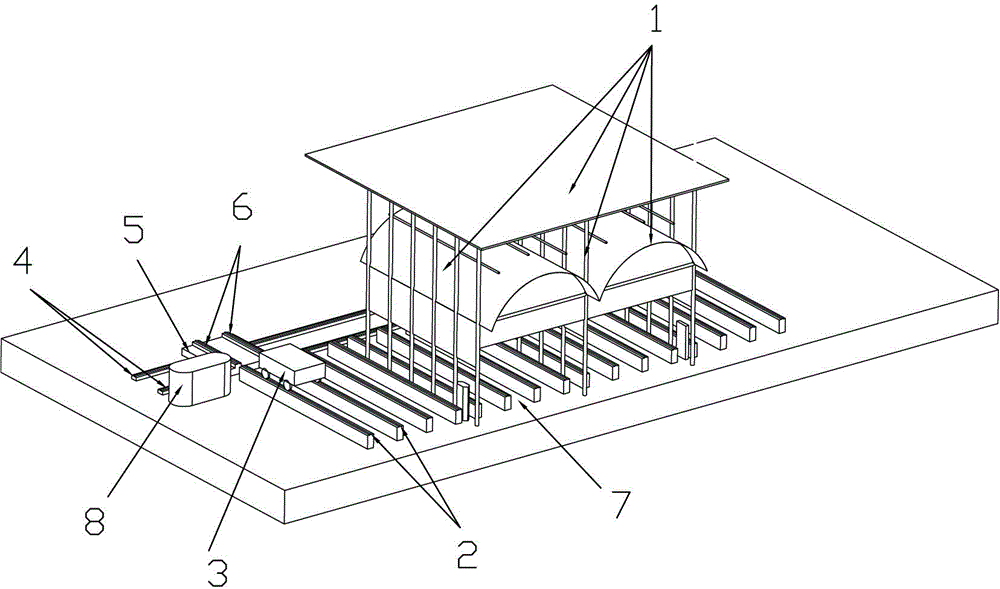

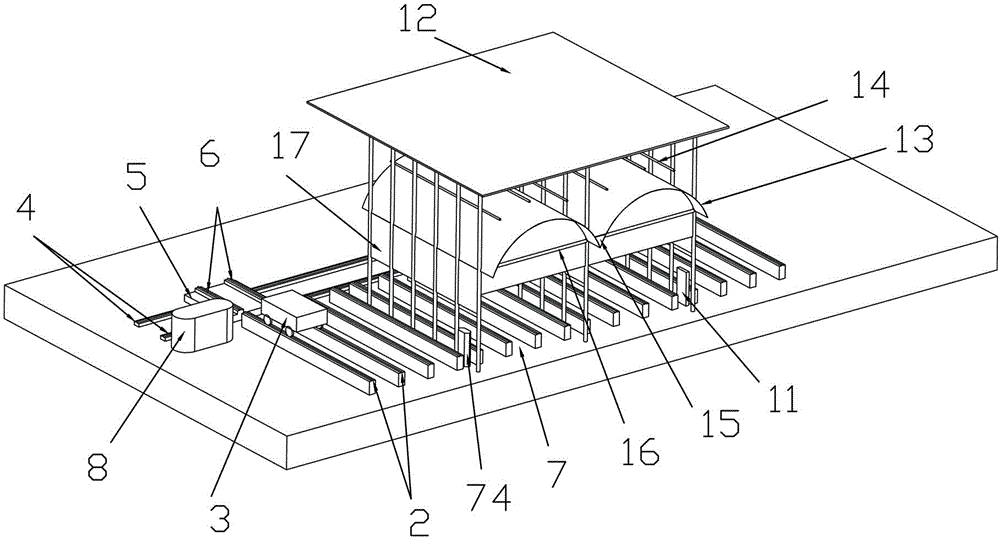

[0032] In this embodiment, the structure of the present invention is described in detail with reference to the drawings.

[0033] See Figure 1 to Figure 5 The large-scale high-efficiency fly maggot cultivation equipment provided by the present invention comprises at least one cultivation workshop with a multifunctional ceiling 1, and at least one feeding machine 3 running along the double-row type distribution track 2 is provided in the cultivation workshop, and the distribution track 2 The front of one end is vertically provided with a main track 4, and the main track 4 is provided with a rail car 5 for the feeder 3 to transfer between different distribution tracks. The rail car 5 is provided with a transfer track 6 horizontally perpendicular to the main track 4, and the transfer track The height of 6 is consistent with the height of cloth track 2, and the workshop ground between the two rows of tracks of cloth track 2 constitutes a breeding bed 7 for fly maggot breeding. T...

Embodiment 2

[0041] In this embodiment, the process steps of the present invention are described in detail with reference to the accompanying drawings.

[0042] See Figure 1 to Figure 5 , and in conjunction with embodiment 1, the fly maggot cultivation process using the large-scale high-efficiency fly maggot cultivation equipment provided by the invention in embodiment 1 may further comprise the steps:

[0043] Step 1: Material preparation, prepare biomass waste in the silo, add auxiliary materials to the biomass waste, use a material mixer, adjust the moisture content of the biomass waste and use it as a culture material or base material.

[0044] Step 2, preparation and hatching of fly eggs.

[0045] Step 3, the preparation for the adjustment of the cultivation equipment, the temperature control of the contact layer 71 of the cultivation bed 7 is adjusted to 25-37 degrees, and the temperature of the air is adjusted to below 37 degrees. In this embodiment, the temperature of the contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com