Sticky trapping type tobacco pest trapper

A technology of traps and smoke bugs, which is applied in the field of smoke bug traps, can solve the problems of point error, unusability, interference with production, etc., and achieve the effects of eliminating visual interference, saving use costs, and reducing counting errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

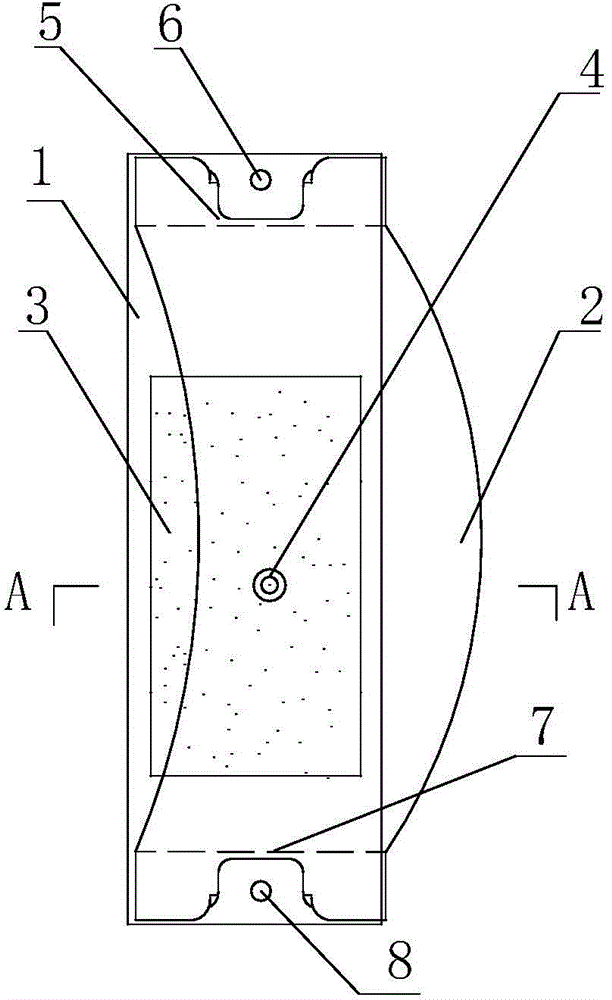

[0037] Such as figure 1 , Figure 5 As shown (split trap), a sticky trapping type tobacco insect trap includes a bottom plate 1, a panel 2, a shellac 3, and a trap core 4 containing tobacco pest sex pheromone; the panel is located above the bottom plate, and the bottom plate and The panels are buckled together, and a trapping cavity 11 is formed between the panel 2 and the bottom plate 1. The sides of the trapping cavity 11 (such as either the left side or the right side, or both the left side and the right side) and The outside is connected (the side is an open end, which is convenient for tobacco insects to enter the trap cavity); sticky shellac (industrial glue for armyworms) 3 is coated on the inner surface of the bottom plate and the panel (that is, the inner surface of the bottom plate is coated with sticky Shellac layer, paste a layer of release paper on the shellac layer, remove the release paper when using, the coating amount of shellac 3 is 0.001-30g / cm 2 ), on the in...

Embodiment 2

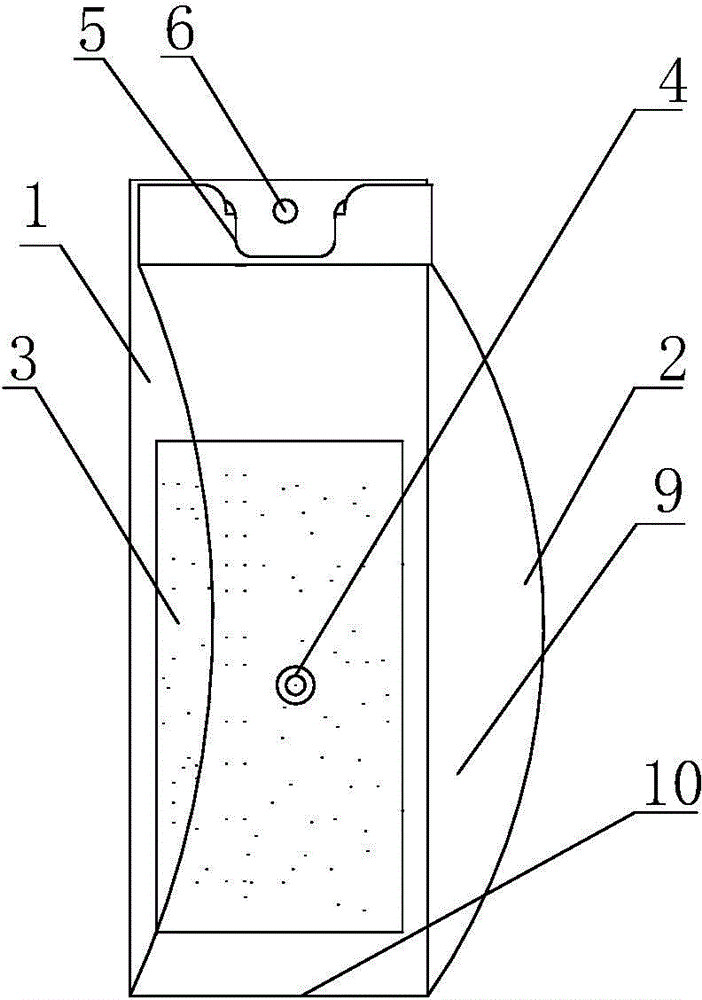

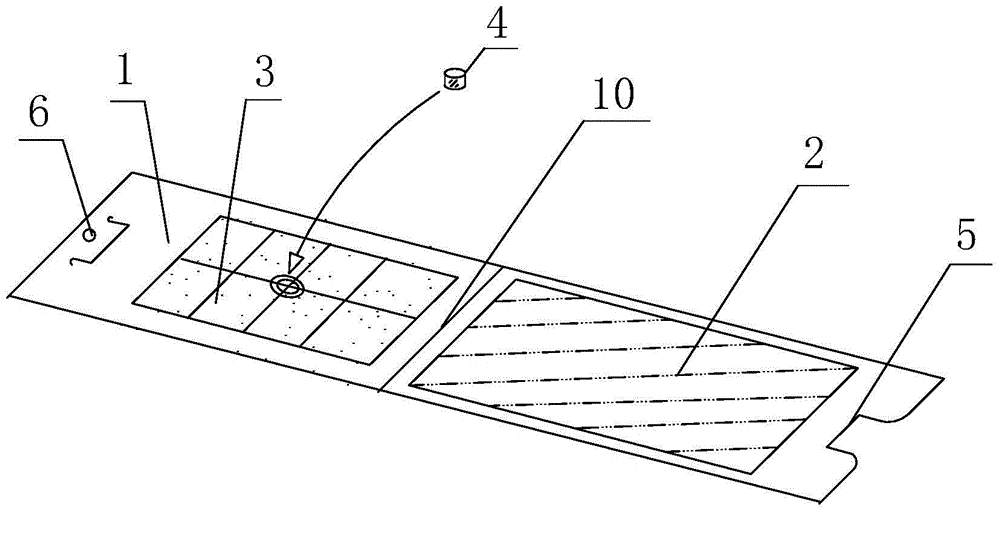

[0041] Such as diagram 2-1 , Figure 2-2 ( Figure 2-2 versus Figure 4 It is a set, which are all embedded with a transparent dust-proof board (integrated trap), a sticky trapping tobacco insect trap, including the bottom plate 1, the panel 2, the sticky shellac 3, and the tobacco pest information Vegetarian lure 4;

[0042] The bottom plate and the panel are integrated (the bottom plate and the panel are directly cut into an integrated type, or the bottom plate and the panel are butt bonded and thermally synthesized into an integrated type), and the center of the integrated bottom plate and the panel is a double fold line 10, The bottom plate and the panel are folded in half with the fold line 10 (the fold line 10 is the rear edge). At this time, a buckle is set at the middle position of the front edge of the bottom plate and the middle position of the front edge of the panel (bottom front buckle 6 and panel front buckle 5). ), first tear off the release paper on the shellac l...

Embodiment 3

[0046] Such as image 3 Shown (panel is an opaque sheet material, split trap), a sticky trapping tobacco insect trap, including a bottom plate 1, a panel 2, a shellac 3, and a lure core 4 containing tobacco pest sex pheromone;

[0047] The panel is a sheet-shaped arc-shaped panel; the middle position of the front edge and the rear edge of the bottom plate is respectively provided with a bottom plate buckle for inlaying the panel (that is, the bottom plate front buckle 6 and the bottom plate back buckle 8; The bottom plate and the panel can be cut into two independent parts), and the middle positions corresponding to the front and rear edges of the panel facing the bottom plate are respectively provided with panel buckles (ie Front panel buckle 5, rear panel buckle 7), first tear off the release paper on the shellac layer before use, and fit the front and back panel buckles into the two bottom plate buckles respectively Inside (the panel is located above the bottom plate, the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com