Instantly sticking type nasal mask

The technology of a nasal mask and an adhesive layer is applied in the field of medical devices, which can solve the problems of increased breathing resistance, poor breathing of users, and small area of filter material, so as to increase the airflow passing speed, improve the smoothness of breathing, and increase the ventilation area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

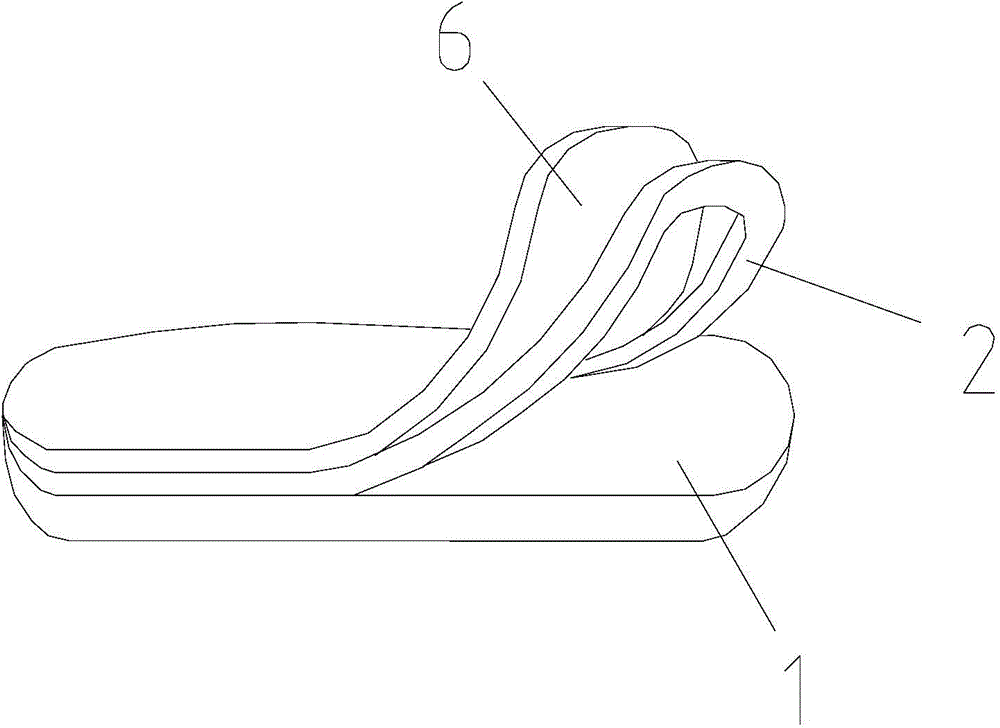

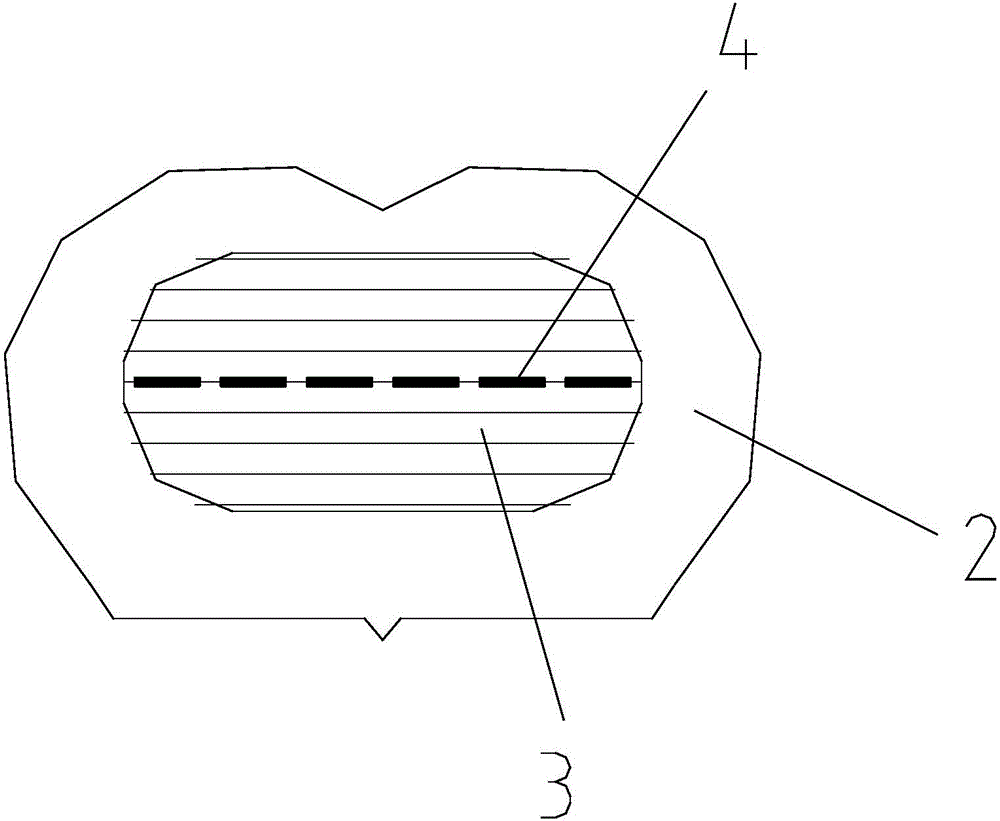

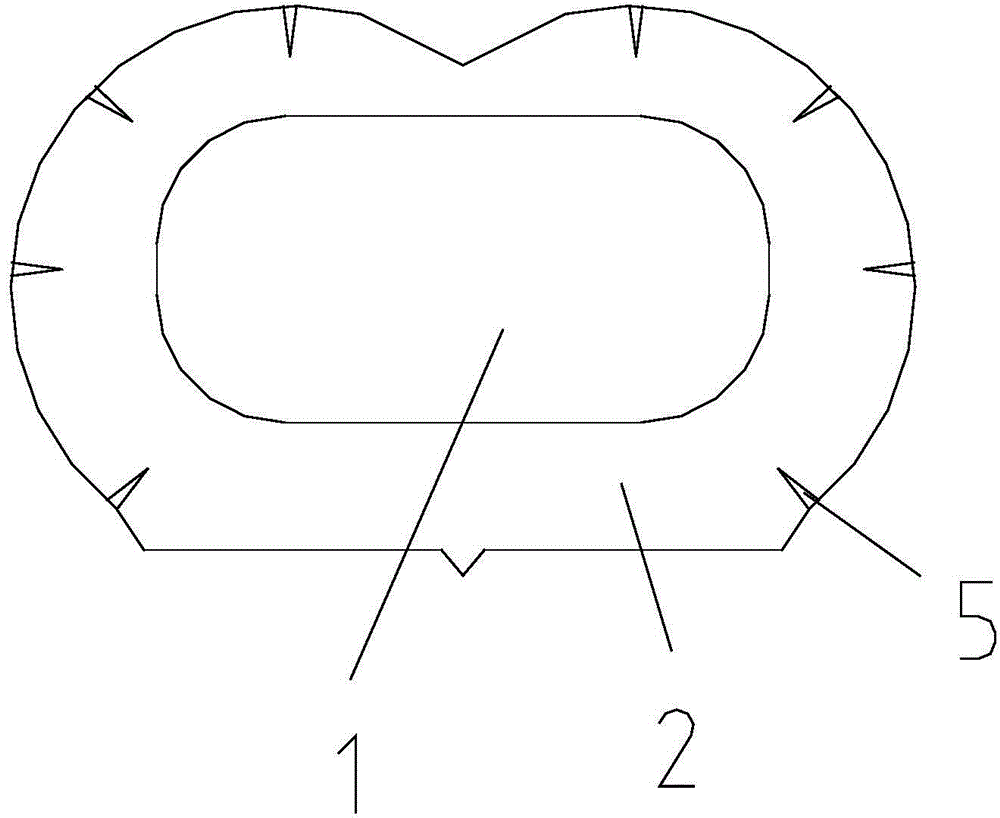

[0023] The instant nasal mask of the present invention, such as Figures 1 to 6 As shown, it includes filter base layer 1 and paste layer 2.

[0024] The adhesive layer 2 is ring-shaped and fixed on the edge of the filter base layer 1 .

[0025] Folds 3 are arranged in the middle of the filtering base layer 1 , and elastic gaps 4 are arranged on the ridges formed by the folds 3 . Such as Figures 4 to 6 As shown, the elastic slit 4 is located on the outer ridge line, and one fold 3 is provided with a plurality of elastic slits 4 .

[0026] Such as figure 1 As shown, the adhesive layer 2 is covered with a protective layer 6 , and the edge of the protective layer 6 is connected with the adhesive layer 2 .

[0027] Such as image 3 As shown, an incision 5 is provided on the outer edge of the filter base layer 1 , and an incision 5 may also be provided on the outer edge of the adhesive layer 2 .

[0028] The filter base layer 1 is an elastic and breathable material such as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com