Surface repairing and shaping device used for metal three-dimensional printing

A 3D printing and surface repair technology, applied in the field of metal 3D printing, can solve the problems affecting the reliability of the processed workpiece, the deterioration of the surface of the molten metal, and the change of the properties of the processed material, so as to improve the processing quality, gas uniformity, and surface quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

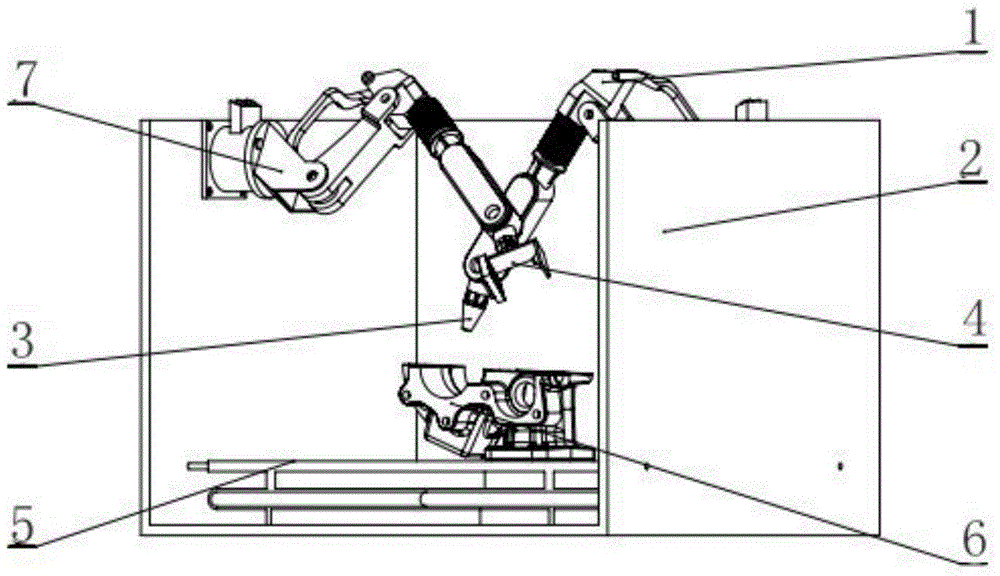

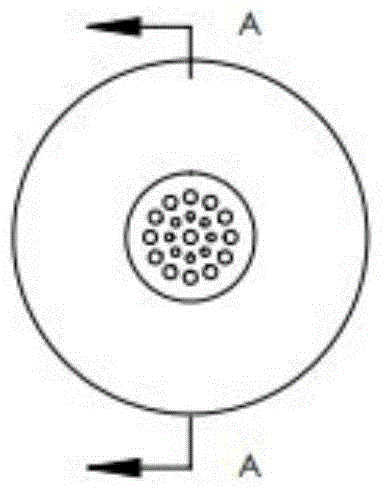

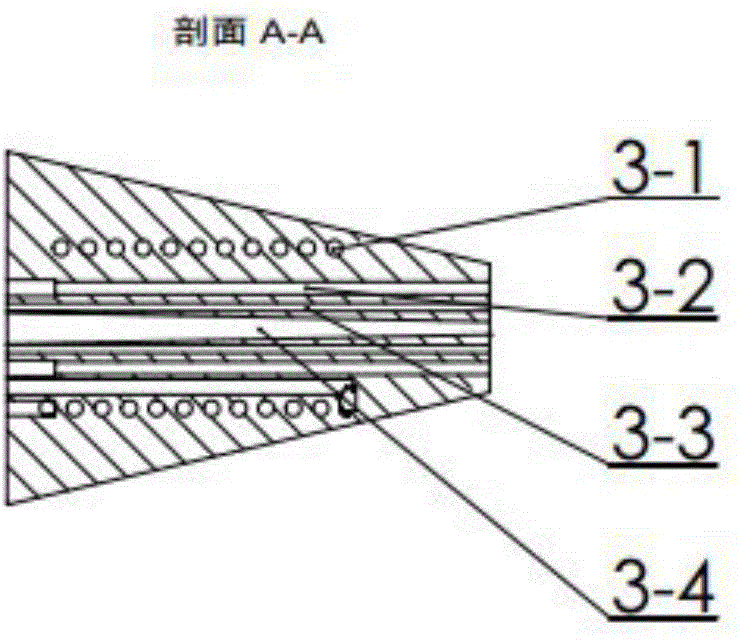

[0022] Such as figure 1 As shown, the present invention is a surface repair and shaping device for metal 3D printing, including a first omnidirectional six-degree-of-freedom mechanical arm 1, a housing 2, a metal 3D printing shaping device 3, a space scanning camera device 4, and a workpiece lifting The pallet 5, the workpiece 6 and the second omnidirectional six-degree-of-freedom mechanical arm 7; the first omnidirectional six-degree-of-freedom mechanical arm 1 and the second omnidirectional six-degree-of-freedom mechanical arm 7 are symmetrically installed on the inner wall of the housing 2; The metal 3D printing shaping device 3 and the space scanning camera device 4 are respectively installed at the end positions of the first omnidirectional six-degree-of-freedom mechanical arm 1 and the second omnidirectional six-degree-of-freedom mechanical arm 7; the workpiece lifting tray 5 is set At the bottom of the shell 2; the workpiece 6 is set on the lifting pallet of the workpie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com