Manual hammer head presser

A press and hammer technology, which is applied in the field of piano parts production equipment, can solve the problems of increased production cost, large floor space, and high equipment cost, and achieve the effects of energy saving, small floor space, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

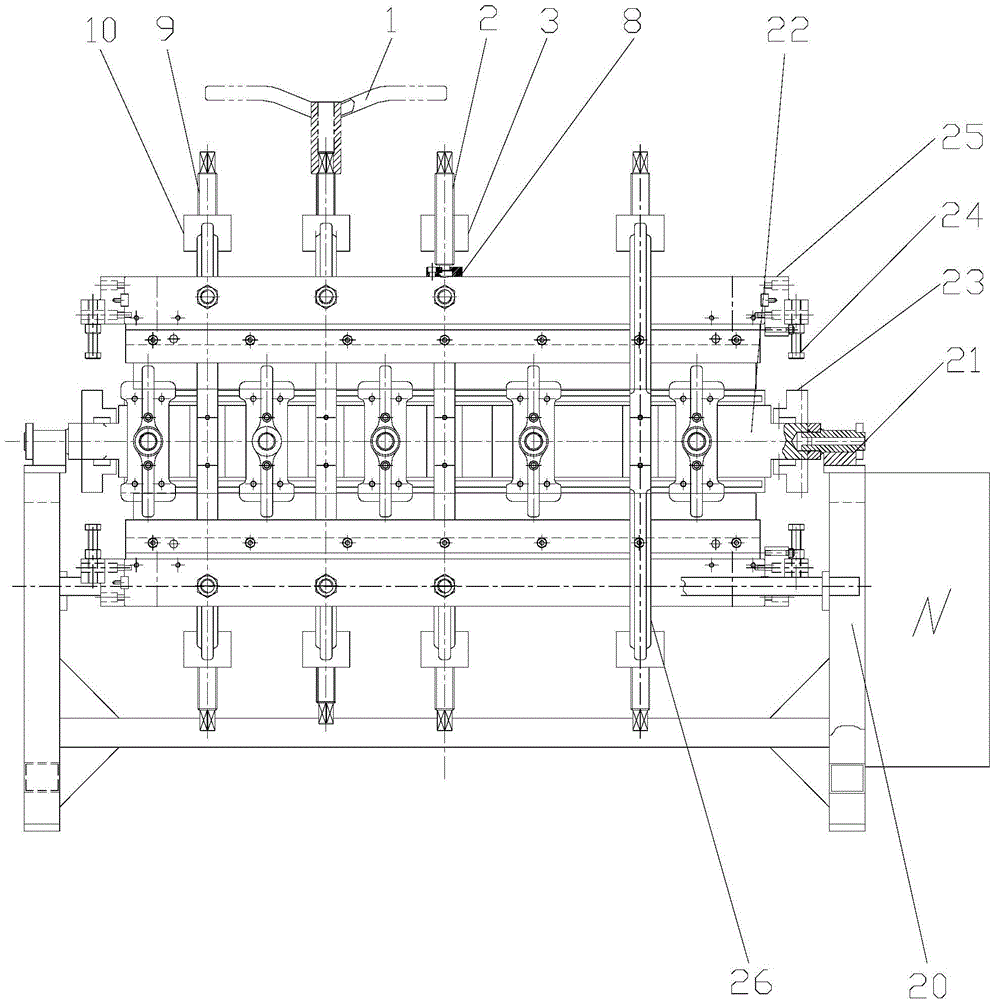

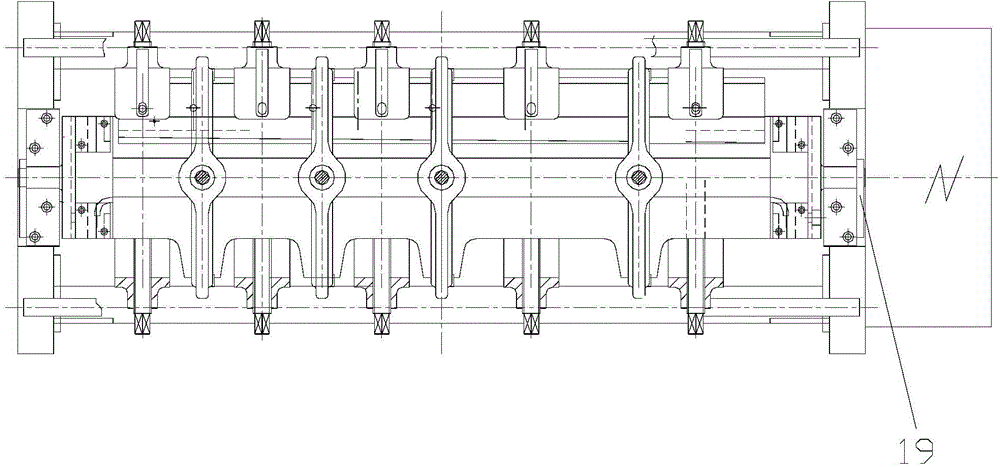

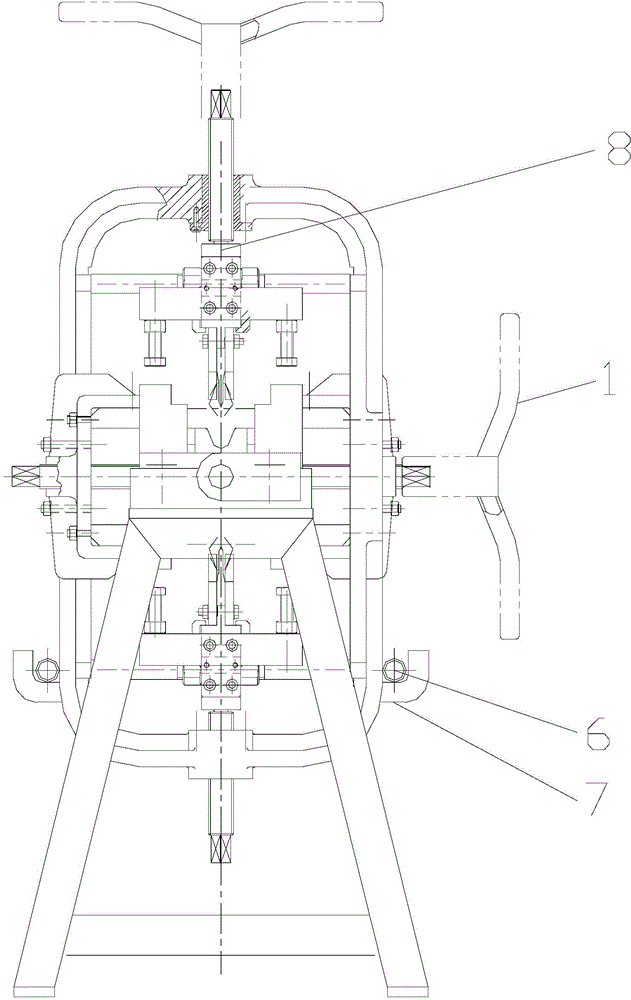

[0033] Manual hammer press machine includes: frame, center shaft, bottom die, left die, right die, upper and lower pressing mechanism, left and right pressing mechanism.

[0034] The upper end surface and the lower end surface of the central axis have the same structure, and are all planes, and the left and right center positions of the upper and lower end surfaces are all provided with a strip groove for the installation of the bottom mold. The structure of the left end face and the right end face of the central shaft is also the same, the main body is a plane, and four protruding ridges are arranged at intervals in the plane for the installation of the radial compression frame. There are five left and right through holes in the central axis for the longitudinal screw to pass through, and the through holes should be staggered with the ridg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com