Railway structure of 10000-ton movable portal crane

A technology for moving doors and cranes, applied in rail systems, load hanging components, transportation and packaging, etc., can solve the problems of increasing the impact force and resistance of lifting equipment, the separation of the bottom plate, and the deformation of the rail in the horizontal direction, and achieve the movement resistance. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

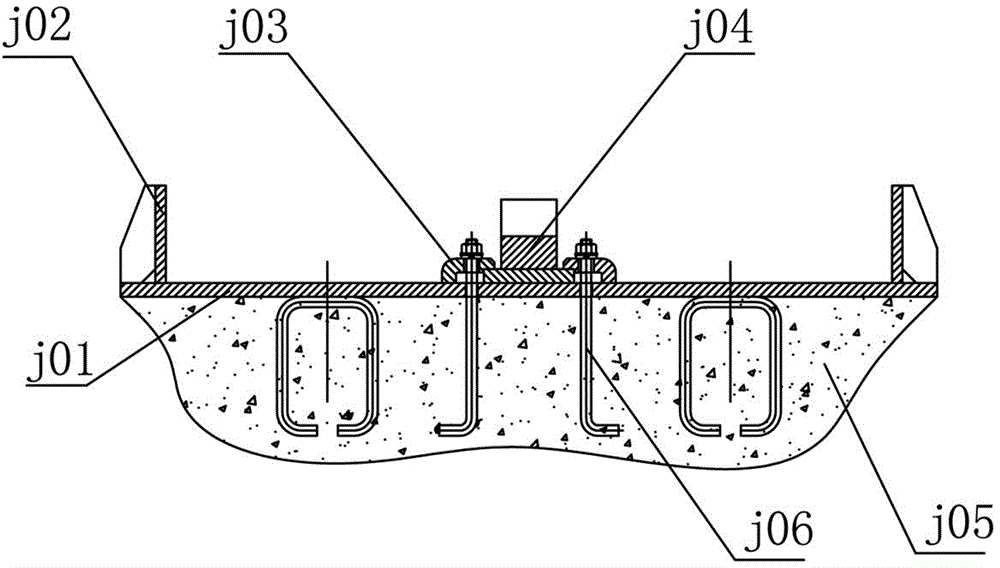

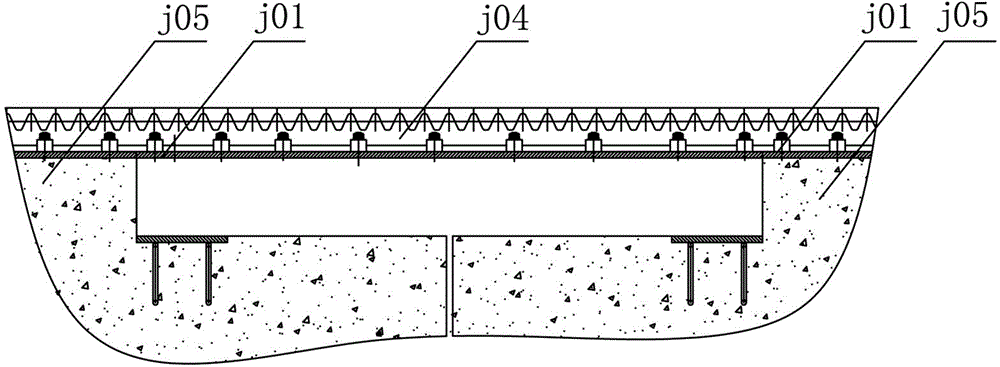

[0020] Such as Figure 4 to Figure 7 As shown, the track structure of a 10,000-ton movable gantry crane includes reinforced concrete j6 laid under track j10, pre-embedded plate j1 embedded in reinforced concrete j6, rack j4, pressure plate j3, two side The baffle j2; the upper surface of the embedded slab j1 exposes the reinforced concrete j6 and is kept flat with the surface of the reinforced concrete j6; the intermittent protrusions of the reinforced concrete j6 form a concrete abutment j5 intermittently distributed under the track j10 The cavity formed between the adjacent concrete piers j5 is provided with a track transition bridge j7; the track transition bridge j7 includes a top plate j71, a bottom plate j72 and a supporting plate j73 between the top plate j71 and the bottom plate j72; The top plate j71 of the track transition bridge j7 is flush with the embedded plate j1 located on the concrete abutment j5, and the bottom plate j72 is fixed on the embedded plate j1 loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com