Preparation method for anti-rust flexible abrasive blasting material

A spray grinding and abrasive technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as large closed holes, affecting the quality of anti-rust or spraying treatment, and high process control requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

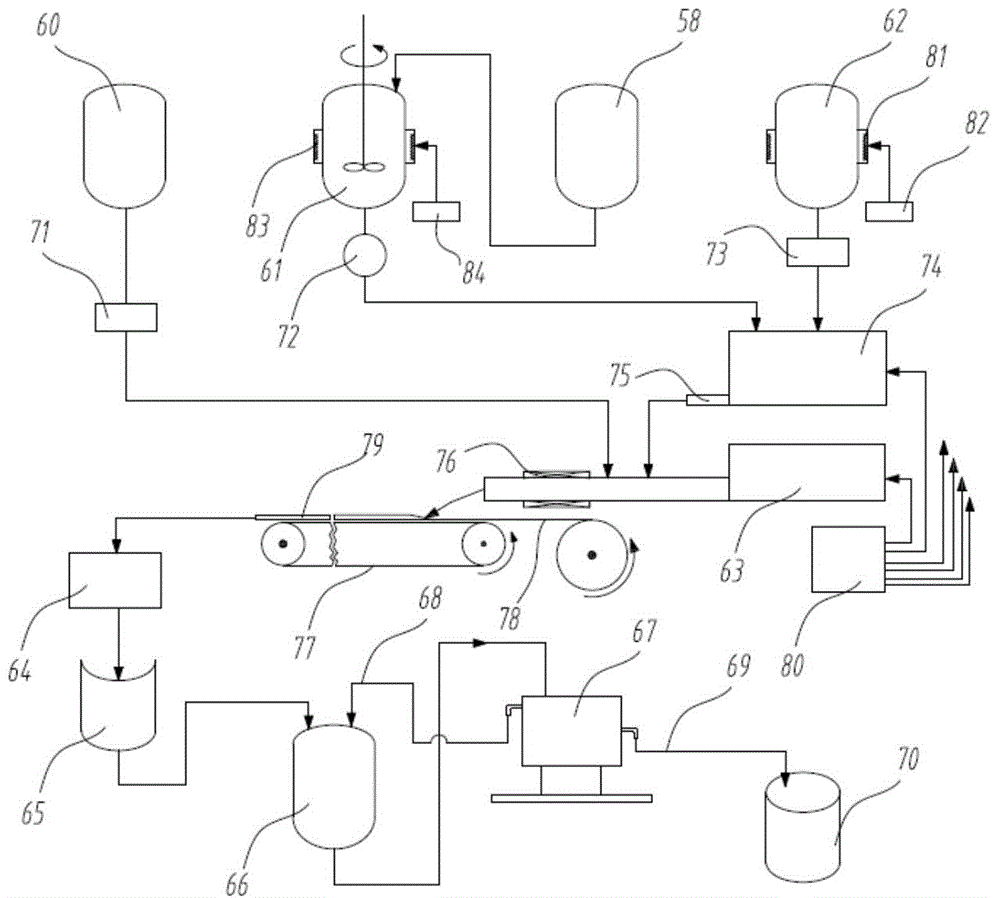

[0050] Such as figure 1 As shown, a schematic diagram of the process flow of a rust-proof flexible medium spray grinding preparation method of the present invention. In the preparation process of the flexible spray grinding material, the prepolymer adopts toluene diisocyanate, the abrasive adopts aluminum oxide, the water-absorbing polymer adopts a fully hygroscopic polymethacrylic acid water-absorbing resin, and the antirust agent adopts a non-aqueous antirust product. The weight ratios of the abrasive particles, the prepolymer, the fully hygroscopic water-absorbing polymer, and the rust inhibitor are respectively 79%, 18%, 2.8%, and 0.2%. After the prepolymer and rust inhibitor are uniformly mixed in the prepolymer storage tank 61, they are heated to about 38°C by the prepolymer heating element 83, and then sent to the mixer 74 by the positive displacement screw pump 72, where they are mixed with the abrasive The abrasive in the storage tank 62 is heated to about 37.8°C by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com