Outer ring-blowing cooling and center oiling device for composite spinning

A technology of composite spinning and cooling device, applied in textile and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of uneven and sufficient oiling, unguaranteed spinning quality, etc., to improve energy Efficiency, reduced energy consumption, low wind speed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

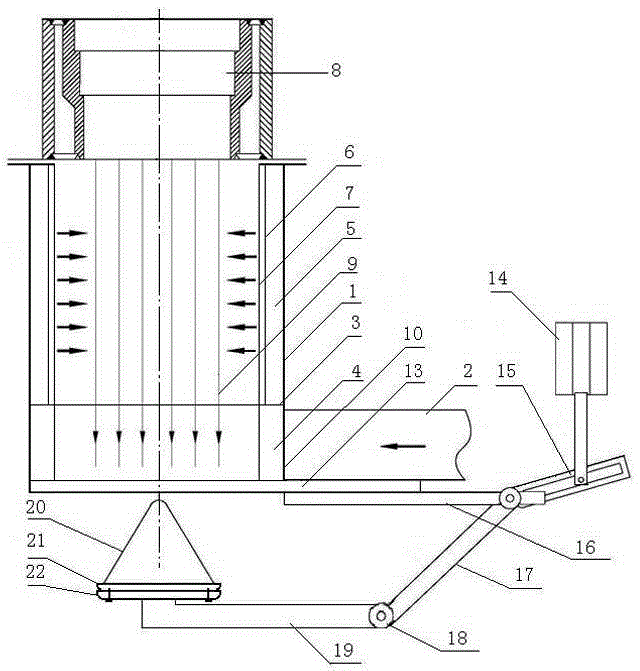

[0016] Embodiment 1: start the refrigerator, the cold air output by the refrigerator enters the air distribution channel 4 through the cold air input pipe 2 and the cold air inlet 10, and the cold air flow is circulated in the air distribution channel 4 due to the aperture limit of the air distribution hole. During the process, the cold air is evenly distributed to the surrounding air duct 5 through the air distribution holes of the cold air deflector 3 .

Embodiment 2

[0017] Embodiment 2: the cold wind that enters the ring blowing channel 5 moves up due to the limitation of the ring blowing hole aperture, and the cold wind is delivered to the ring between the ring blowing plate 6 and the ring blowing net 7 through the ring blowing holes on the ring blowing plate 6 space, and then enter the cooling channel where the spinning 9 falls in the ring blowing net 7 through the mesh of the ring blowing net 7, and the spinning 9 is cooled by blowing cold air from the outer ring.

Embodiment 3

[0018] Embodiment 3: At the same time when the spinning device starts to unload, the control system starts the pneumatic push-pull device 14 of the mobile unit, the high-pressure gas pushes the push-pull rod down, and the sliding pin at the connecting end of the push-pull rod moves in the chute of the slide rod 15 , push down the slide bar 15, because the connecting end of the slide bar 15 is connected at a fixed angle with one end of the connecting rod 17, and is positioned on the fixed bar 16 through the movable pin, the connecting rod 17 swings to the left with the movable pin as the center of the circle, and the connecting rod 17 The other end is connected with the support rod 19 by a hinge 18, and the connecting rod 17 pushes the support rod 19 to move toward the center of the outer ring cooling device. Because be connected by hinge 18 between connecting rod 17 and support bar 19, the movement of support bar 19 keeps horizontal state all the time, the oiling unit that is i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com