Powder spreading vehicle

A technology for spreading vehicles and powders, which is applied to roads, road repairs, roads, etc. It can solve the problems of irreconcilable spreading quantity, low spreading accuracy, and spreading quantity affected by vehicle speed, etc., to achieve remote monitoring and remote operation, and ensure spreading accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

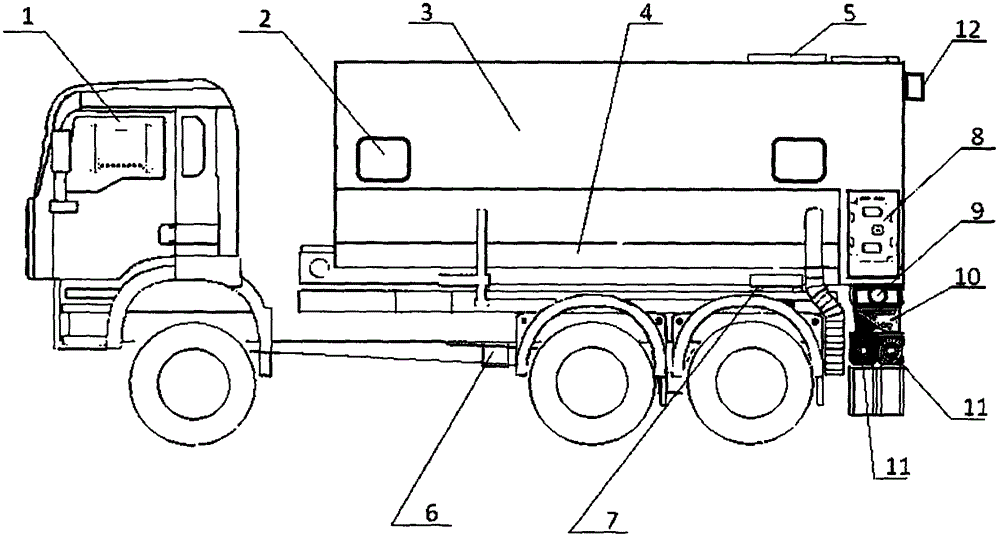

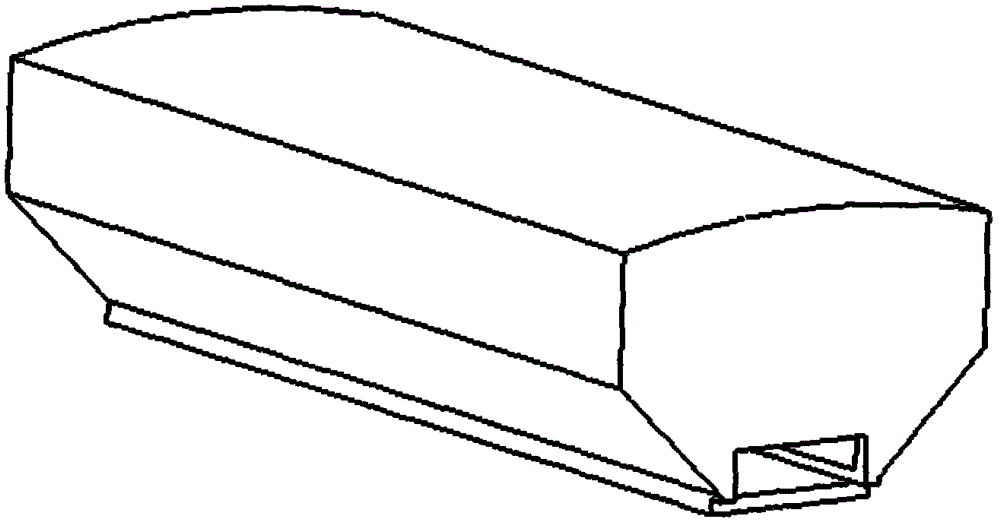

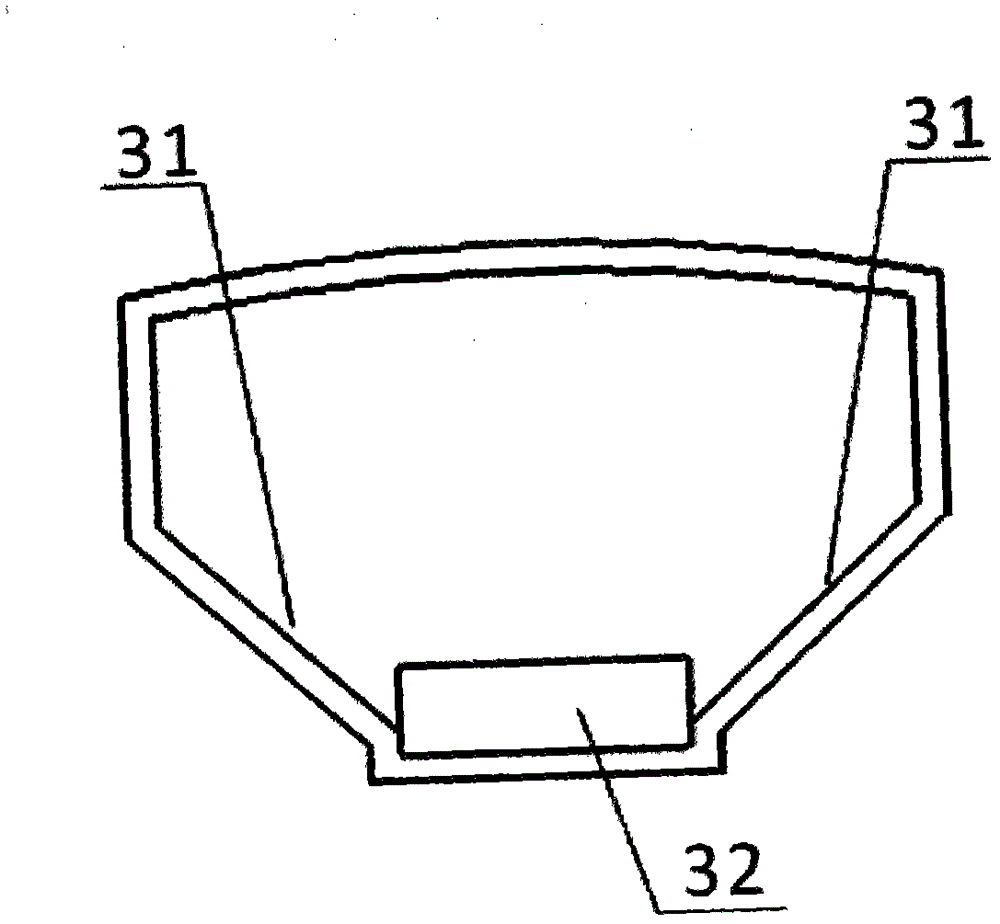

[0026] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, a powder spreading vehicle includes an automobile chassis, a powder silo 3, a chain transmission device 4, a small spreading silo 10, a precision spreading device 11 and an electro-hydraulic system 8. The display controller 1 used to display the working data of the powder spreader. The display controller 1 is connected to the electro-hydraulic system 8 through CANBUS for communication. The powder silo 3 is installed on the chassis of the vehicle. Weighing module 7. The weighing module 7 is used to detect the powder weight in the powder silo 3. The chain transmission device 4 is arranged in the outlet groove 31 at the bottom of the powder silo 3. The chain transmission device 4 is mainly composed of the driving sprocket 41 and the The moving sprocket 42 and the chain 43 are composed, the connecting ribs 44 are arranged between the chains 43, the driving sprocket 41 is driven to rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com