Double-block type sleeper production line and production process thereof

A production line, two-block technology, used in manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of increased automation of the production line, too many people in the maintenance area, and insignificant heating curve. The effect of increasing the number of rollers and using fewer people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

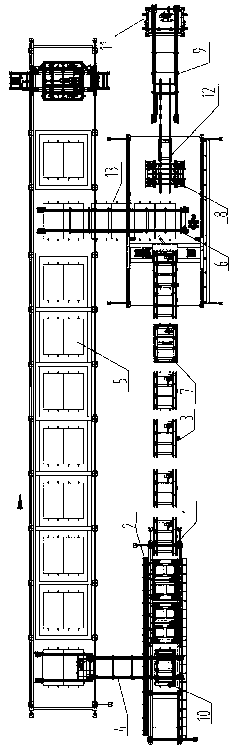

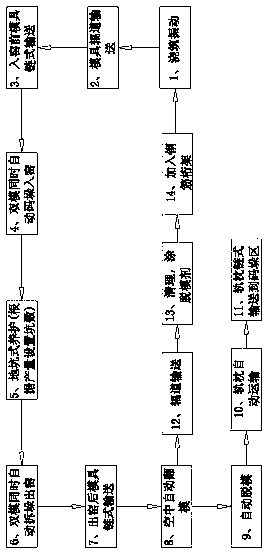

[0024] The invention specifically relates to a double-block sleeper production line and its technology, which are mainly used for the production of 4×1 short-form sleepers in high-speed railways.

[0025] The specific production line is composed of: a double-block sleeper production line, including a vibrating table 2, a distributing machine 1 that can slide left and right along the slide rail is arranged above the vibrating table 2, and a Lifting roller table 10, on the side of lifting roller table 10, a first mold chain conveyor 4 vertically connected to the slide rail is provided. Tilting platform 7, conveying roller table 3 right end is provided with second mold chain conveyor 13, is provided with aerial automatic mold turning machine 6 on the second mold chain conveyor 13, first mold chain conveyor 4 and The free end of the second mold chain conveyor 13 is connected by an automatic stacker 5, and a sleeper output device is provided on the right side of the conveying rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com