Hollow slab bridge structure enhancing transverse rigidity

A technology for hollow slab bridges and transverse stiffness, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of hinge joint damage, veneer stress, and lower bearing capacity of the whole bridge, and achieve lateral connection strengthening and shear resistance Strong, large shear area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

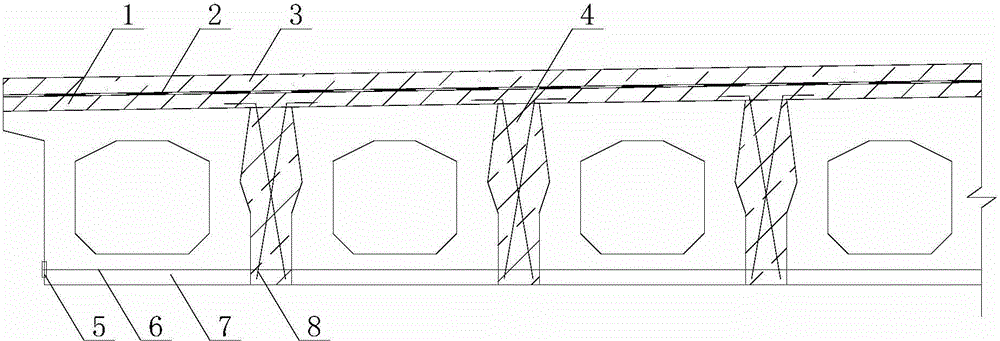

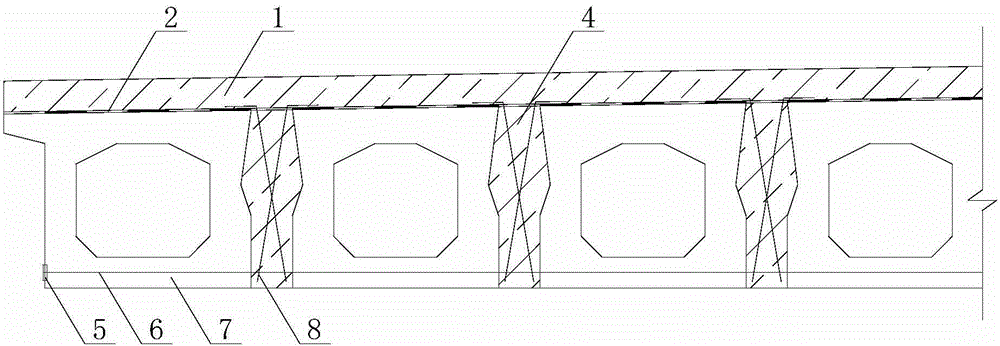

[0011] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0012] The structure of the bridge is a 15-meter simply supported slab bridge with a width of 9.8 meters. The simply supported slab bridge is composed of 8 prefabricated slabs, of which the prefabricated side girders are 1.2 meters wide and the prefabricated middle girders are 1.0 meters wide.

[0013] After the prefabricated slabs are erected, the distance between adjacent prefabricated slabs is 20 cm at the top of the beam and 20 cm at the bottom of the beam. A total of 3 transverse prestressed tendon pipes are reserved at the mid-span and 3 meters on both sides of the mid-span. Insert the transverse prestressed tendon into the reserved hole, and install the anchor at the fixed end. Cover the transverse prestressed tendons between the prefabricated panels with bellows. The formwork for the hinged joints is then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com