Strip-shaped back bolt anchoring structure, stone back bolt anchoring system and anchoring method

An anchoring structure and anchoring system technology, which is applied in the direction of building components, building structures, covering/lining, etc., can solve the problems of small shear surface and unreliable anchoring, and achieve the effects of avoiding failure, facilitating processing quality, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

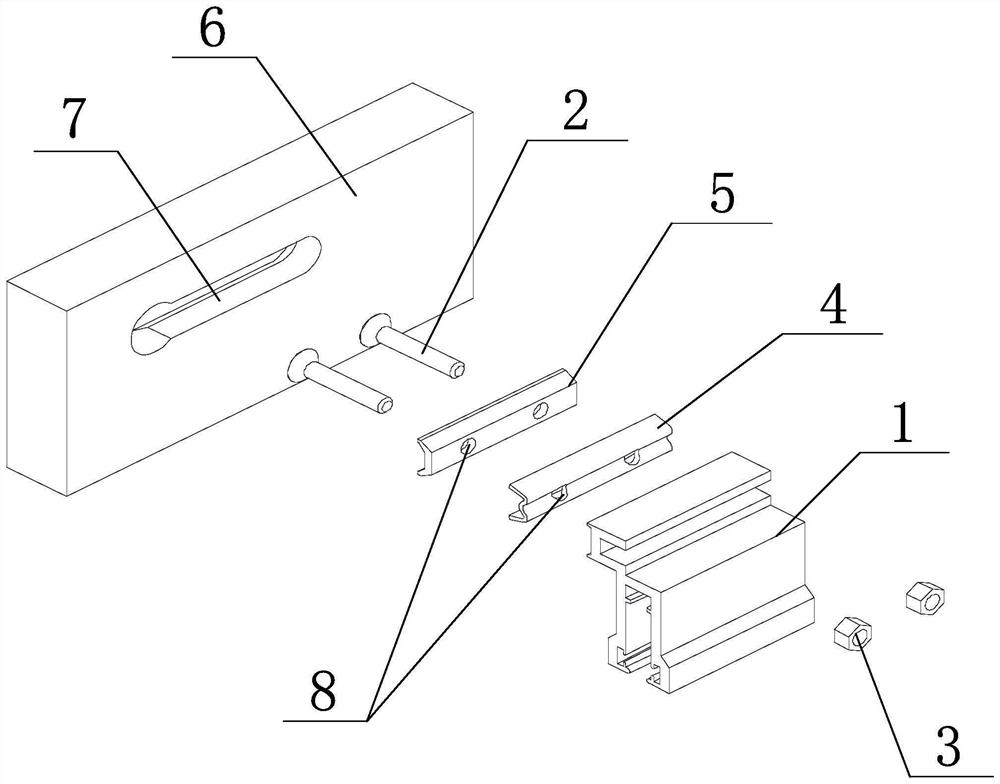

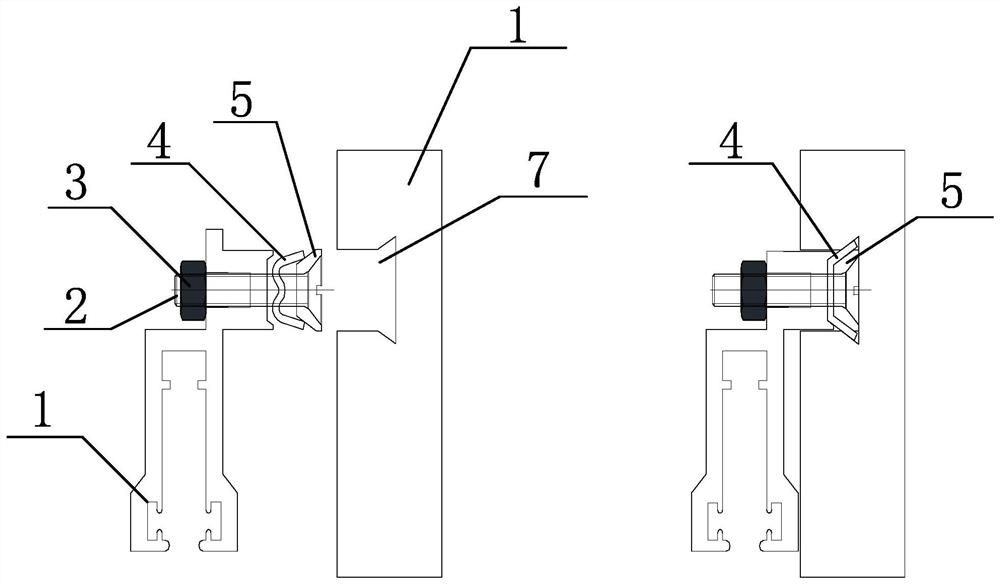

[0036] like figure 1 As shown, a backbolt anchoring structure provided by the embodiment of the present invention includes a strip-shaped support 5 and an expansion member 4; the expansion 5 is used to be arranged between the support 4 and the hanger 1, and the expansion Part 4 can produce outward expansion deformation in width when receiving the clamping force of support part 5 and pendant 2; both support part 5 and expansion part 4 are provided with screw holes 8, and screws 2 pass through the screw holes of the support part in turn , the screw hole of the expansion piece and the screw hole of the pendant are connected with the nut 3 .

[0037] In the back bolt structure of the present invention, when the expansion part is subjected to clamping force, it can produce outward expansion deformation so that it can be stuck in the groove processed by the stone. Compared with the existing anchor structure of the back bolt and the inverted cone back bolt hole, the stone material T...

Embodiment 2

[0041] like figure 1 As shown, a strip-shaped backbolt anchoring structure provided by the embodiment of the present invention includes a strip-shaped support 5 and an expansion piece 4; the expansion piece 5 is used to be arranged between the support 4 and the hanger 1, so The side of the expansion element close to the support element has a slot, and the width of the support element gradually increases along the direction away from the expansion element. The support element can be inserted into the slot to expand the expansion element in the width direction. Specifically, The cross section of the expansion part is "M" shape; the support part 5, the expansion part 4 and the hanging part 1 are provided with two screw holes 8 along the length direction, and the screws 2 pass through the screw holes of the support part, the expansion part and the The screw holes of the pendant 1 and the screw holes of the pendant 1 are connected with the nut 3.

[0042] In the anchoring structur...

Embodiment 3

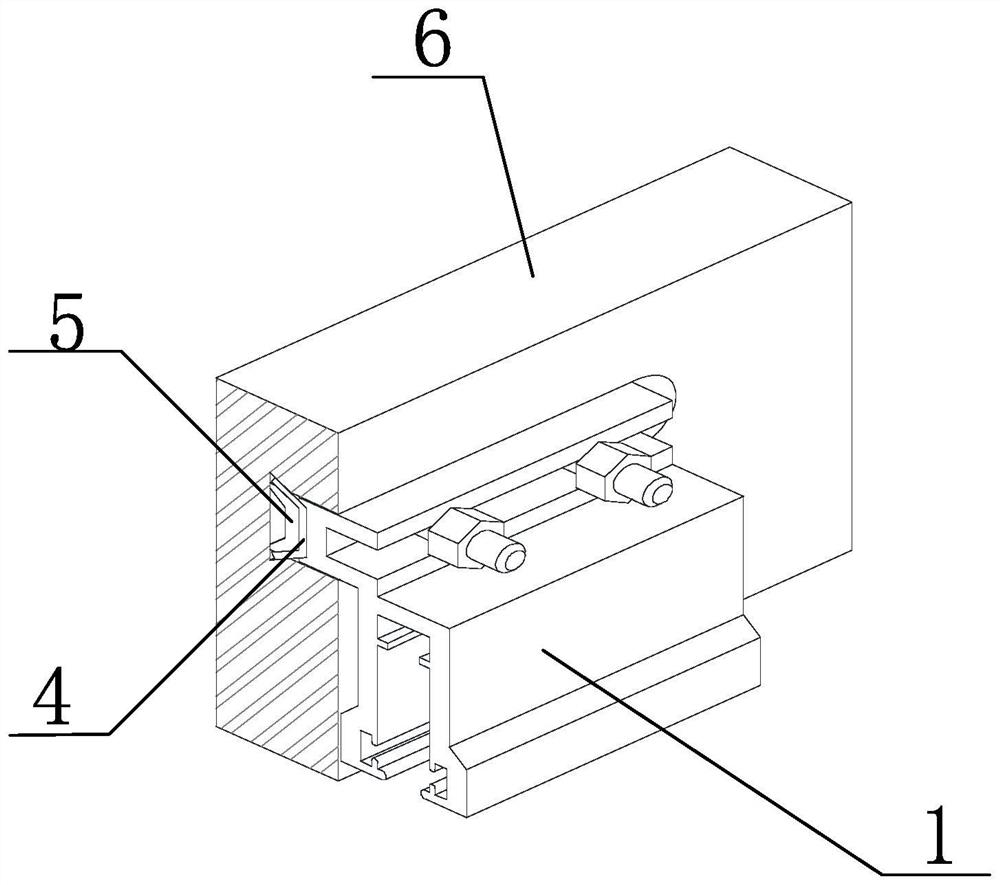

[0046] like Figure 1-3 As shown, a strip-shaped stone back bolt anchoring system provided by the embodiment of the present invention includes stone 6, support 5, expansion 4 and aluminum alloy pendant 1, a strip-shaped dovetail groove 7 is opened on the back of the stone, and the support 5 , the expansion part 4 and the pendant 1 are provided with screw holes 8, and the screws 2 pass through the screw holes of the support part 5, the screw holes of the expansion part 4 and the screw holes of the pendant 1 in order to connect with the nut 3, and the support part 5 and the expansion part 4 is set in the dovetail groove 7, and the aluminum alloy pendant 1 and the support piece 5 clamp the expansion member 4 by tightening the nut 2, and the edges on both sides of the expansion member 4 expand outward in the width direction and snap into the dovetail groove 7.

[0047] The present invention adopts the external expansion structure of the dovetail groove and the expansion part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com