Petroleum drilling fluid separating sieve based on separating screening net slideways

A technology for oil drilling and screening nets, which is used in earth-moving drilling, flushing wells, wellbore/well components, etc. It can solve the problems of high energy consumption of filtering equipment, inconvenient operation, low screening efficiency, etc. Time saving, convenient replacement and cleaning, and the effect of improving filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

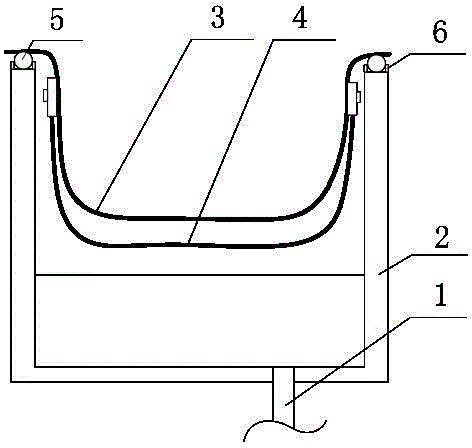

[0033] The oil drilling fluid separation screen based on the screen slideway includes a filter cylinder 2 with a discharge port 1 at the bottom, and an upper screen 3 and a lower screen 4 arranged in the filter cylinder 2 .

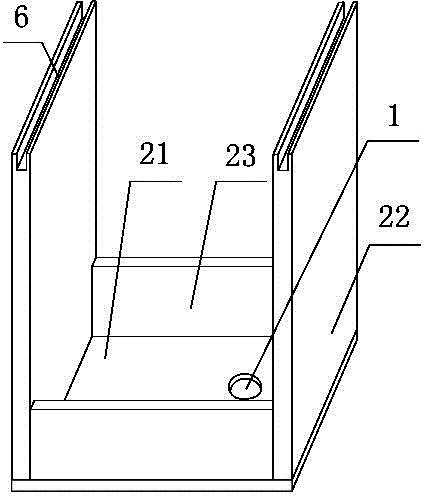

[0034] Such as figure 1 with image 3 As shown, the filter cylinder 2 is composed of a base plate 21 with a discharge port 1, a support plate 22 whose bottom end is fixed on the base plate 21 and oppositely arranged, and is arranged on the base plate 21 to prevent oil drilling fluid from flowing out from the base plate 21 and Its top is lower than the coaming plate 23 of lower screening net 4 and forms.

[0035] The longitudinal section of the upper screen 3 is "U"-shaped, and rollers 5 are arranged on both sides of its top, and the top of the support plate 22 is provided with a slideway 6 that cooperates with the rollers 4, and is used to make the upper screen 3 A power device that moves horizontally with the lower screen 4 simultaneously.

[0036] In...

Embodiment 2

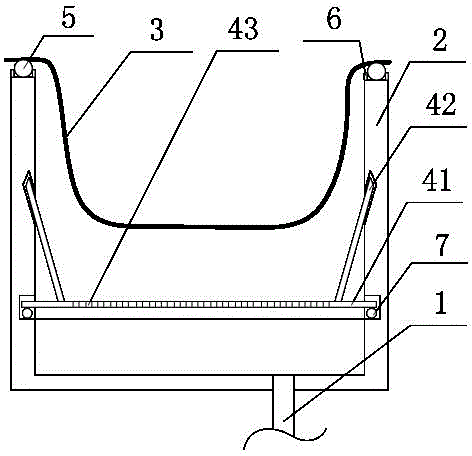

[0039] The difference between this embodiment and Embodiment 1 is that the structure of the lower screening net 4 is different in this embodiment, and the specific setting method is as follows:

[0040] The lower screening net 4 described in the present embodiment comprises a plate-shaped filter screen 41, two deflectors 42 whose bottom ends are fixed on the plate-shaped filter screen 41, and filter holes 43 arranged on the plate-shaped filter screen 41; The hole 43 is located between two deflectors 42, and the top of the deflector 42 extends into the support plate 22; as figure 2 shown.

Embodiment 3

[0042] The difference between this embodiment and Embodiment 2 lies in that in this embodiment, the connection mode between the plate filter 41 and the support plate 22 is optimized, and the type of power device is changed.

[0043] In this embodiment, the plate filter 41 is connected to the support plate 22 through a sliding connection 7 . The power device is a linear moving cylinder, and the linear moving shaft of the linear moving cylinder is provided with a connecting rod for connecting the upper screen 3 and the lower screen 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com