A method and device for accurate calibration of absolute position of shearer based on UWB

A technology of absolute position and calibration method, which is applied in the direction of earthwork drilling, cutting machinery, etc., can solve the problems that the accuracy is difficult to guarantee and the absolute positioning of the shearer cannot be realized, and achieve the effect of ensuring accuracy, high bandwidth, and large system capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

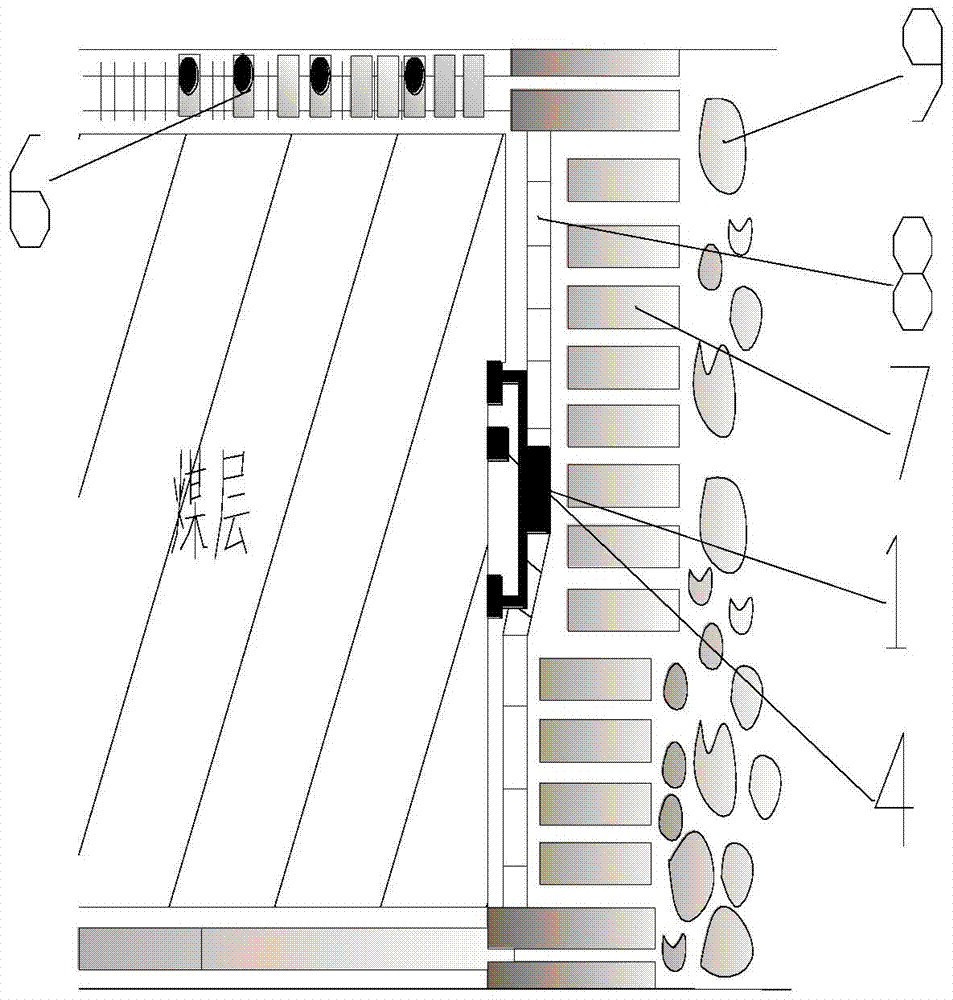

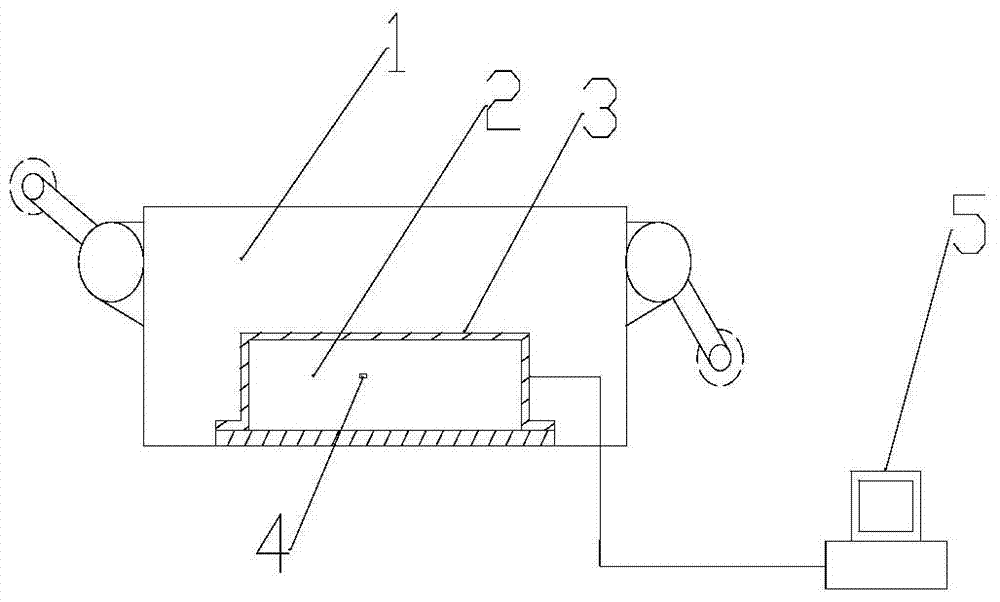

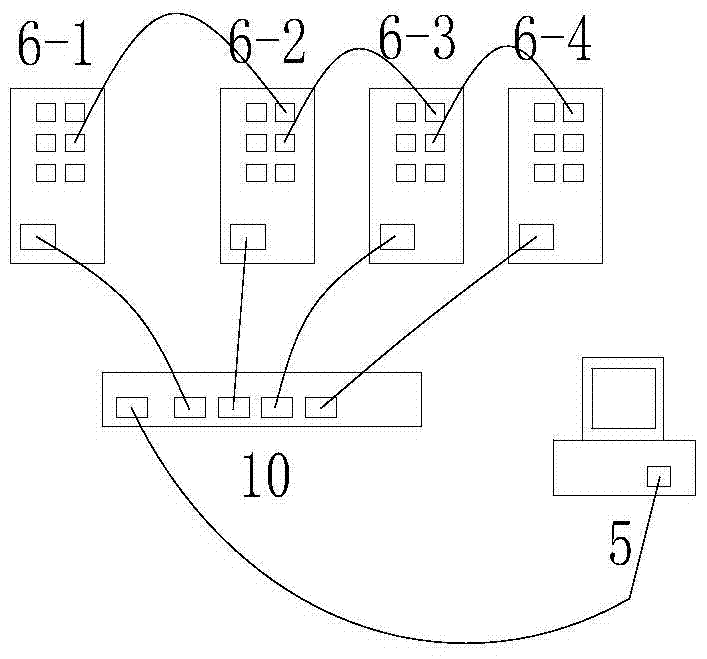

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] UWB technology has the following important advantages:

[0032] (1) Strong anti-interference performance: UWB signals disperse weak radio pulse signals in a wide frequency band during transmission, and the output power is even lower than the noise generated by ordinary equipment. When receiving, the signal energy is restored, and the spreading gain is generated in the process of despreading. (2) High transmission rate: The data rate of UWB can reach tens of megabits per second to hundreds of megabits per second, and the rate has been greatly improved compared with other methods. (3) Extremely wide bandwidth: The bandwidth used by UWB is above 1GHz and up to several GHz, and it can work simultaneously with the current narrowband communication system without interfering with each other. This is in today's increasingly tight frequency resources. A new time-domai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com