Spiral tube heat exchanger suitable for aviation engine

A tubular heat exchanger and aero-engine technology, which is applied in the cooling of engines, engine components, turbines/propulsion devices, etc., can solve problems affecting the overall performance of the engine, loss of external air pressure, and small cooling capacity , to achieve the effects of compact structure design, extended life, and improved heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

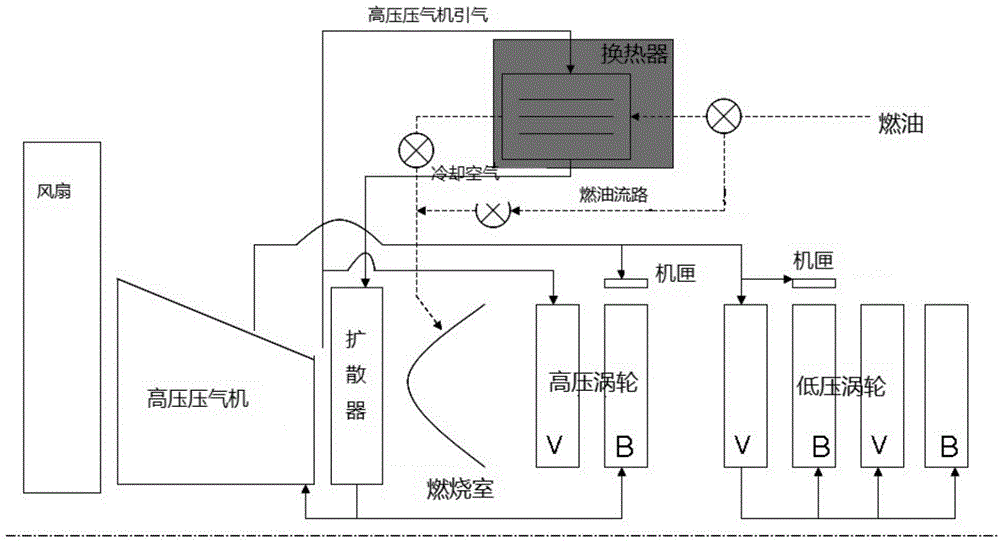

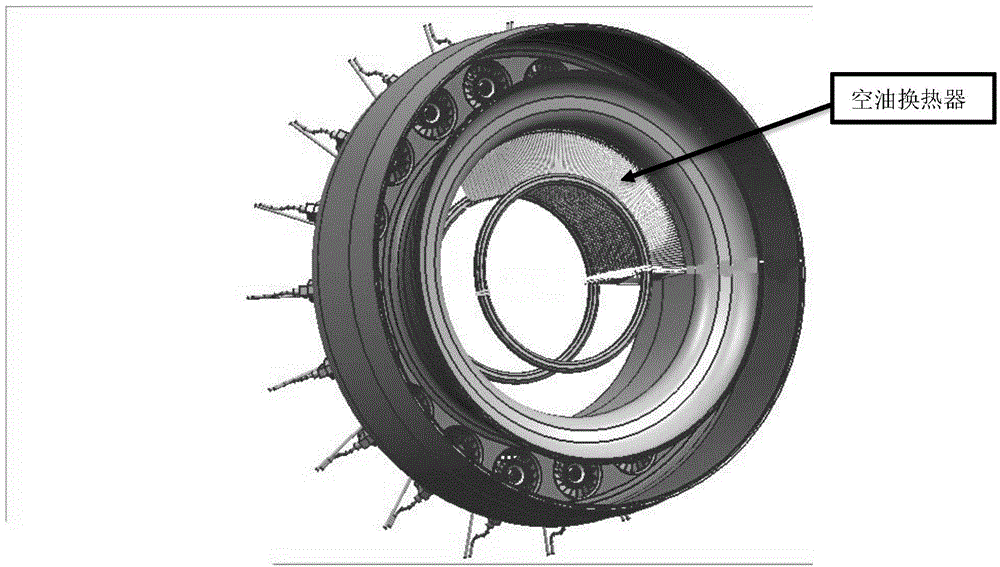

[0029] The present invention is a spiral tube heat exchanger suitable for aero-engines, such as Figure 4 As shown, the heat exchanger includes a mixing chamber at the inlet and outlet and stainless steel tube bundles arranged radially in a circular ring. The stainless steel tube bundle is composed of stainless steel tubes with a diameter of about 2-3mm and a wall thickness of 0.2-0.3mm arranged radially in a circular ring. In order to ensure that the parameters such as the pressure and temperature of the fluid in each heat exchange tube are basically the same, a circular mixing chamber is designed at the inlet and outlet of the heat exchange tube; Carry out convective heat exchange, through the heat conduction of the heat exchange tube and the convective heat exchange between the inner wall of the heat exchange tube and the aviation fuel, the air tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com