A drug-wound stress release device

A stress-releasing and drug-carrying technology, applied in jet propulsion, rocket engine, machine/engine, etc., can solve the problems of changing engine work, short range, and low energy of double lead-2 propellant, so as to reduce stress, Easy batch winding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

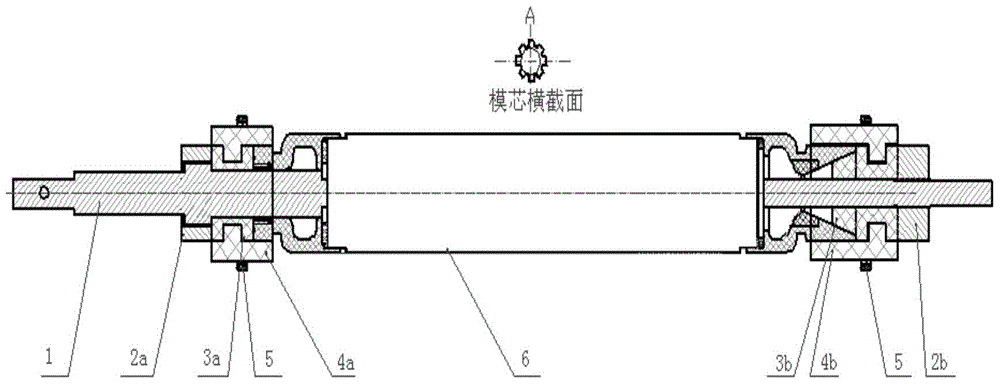

[0009] Such as figure 1 As shown, it is an assembly drawing of the medicine-wrapped stress relief device of the present invention when in use.

[0010] The front positioning ring 4a is inserted into the front clamping groove 3a and tightened by the throat clamp 5 to form a front positioning tool; the rear positioning ring 4b is inserted into the rear clamping groove 3b and is tightened by the throat clamp 3b to form a rear positioning tool, which is positioned before the mold core 1 is inserted successively. Frock, powder charge 6, rear positioning frock are also limited by the front stop ring 2a and the back stop ring 2b. Then install the assembled grain on the winding machine for winding. The grain is stressed by the tension of the fiber during winding. Excessive stress will lead to abnormal operation of the propellant or even dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com