A high back pressure plasma igniter

A plasma and high back pressure technology, applied in the direction of engine ignition, machine/engine, engine components, etc., can solve problems such as failure to work, and achieve the effect of strong ignition ability, light weight, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with specific implementation examples.

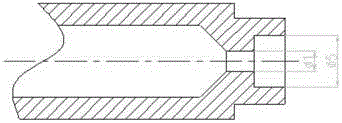

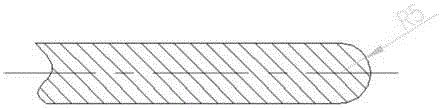

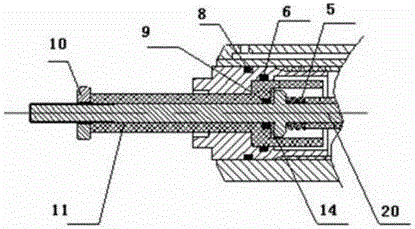

[0018] 1. see figure 1 and Figure 4 , a high back pressure plasma igniter is designed, including a housing 3, a cathode 20, an anode 1, an air inlet 7, a terminal post 13, a cyclone 2, a sealing ring structure and an insulating sleeve structure, an adjusting nut 12, Spring 5, support 17, restrictor 4 and inner nut 15, wherein the insulating sleeve adopts ceramic material, and the support also adopts ceramic material.

[0019] The inner cavity of the housing 3 is a concave structure, and the restrictor 4 is fixed at the bottom by a bracket 17 and an inner nut 15, and the external thread of the inner nut engages with the inner thread of the housing 3, so that the restrictor 4 And bracket 17 is clamped and fixed in the housing. The diameter of the air-connecting hole on the restrictor 4 is 0.5mm, and the air flow rate is stabilized by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com