Base plate supporting device and method and vacuum drying device

A technology of vacuum drying equipment and supporting devices, which is applied in the direction of drying solid materials, dry cargo handling, drying chambers/containers, etc., which can solve problems such as high risk of failure, complicated design and operation of supporting devices, and reduce display defects and design Difficulty, quality improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

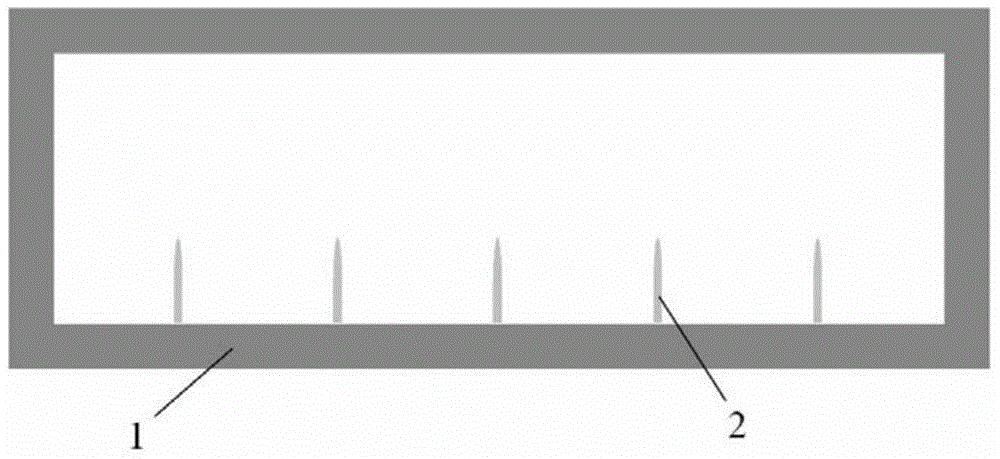

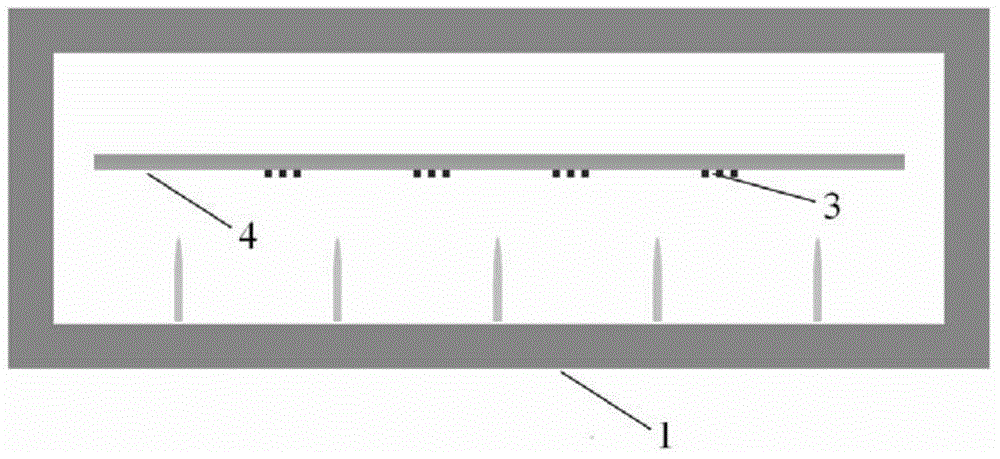

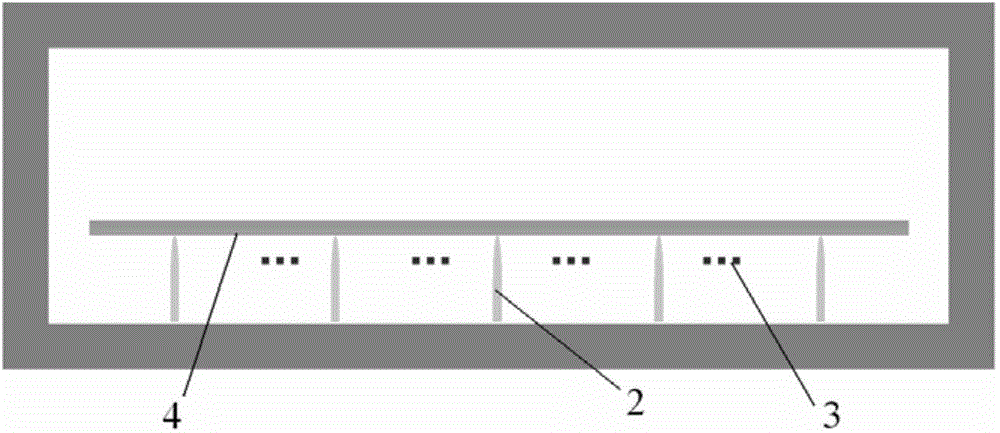

[0054] As a first embodiment of the present invention, the schematic diagram of the fixing mechanism 6 is as follows Figure 7a-Figure 7c Shown, the schematic diagram of lifting mechanism 7 is as Figure 8a-Figure 8c as shown, Figure 9a-9c It is a schematic diagram of the combination of the fixing mechanism 6 and the lifting mechanism 7 in this embodiment.

[0055] In the first embodiment, the end surface of the through hole 62 is a closed figure, a plurality of through holes 62 are evenly arranged in the table 61 , and the shape of the flat portion 71 matches the shape of the through hole 62 at the corresponding position. Preferably, the closed figure includes a rectangle or a circle. Correspondingly, the shape of the flat part includes rectangle or circle. The table top 61 is supported by a plurality of pillars 63, and the bottom of the pillars 63 is fixed on the bottom of the chamber 1 of the vacuum drying equipment (refer to Image 6 ).

[0056] The lifting mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com