Embrittling splitting and clamping device used for connecting rod cap and connecting rod body with high strength and toughness steel

A technology of clamping device and connecting rod cover, applied in the field of expansion clamping device, connecting rod cover and connecting rod body brittle expansion clamping device, which can solve the error, manpower and material force between connecting rod cover and connecting rod body Support large, connecting rod big end hole deformation and other problems, to achieve the effect of noise reduction service life, low cost, good bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

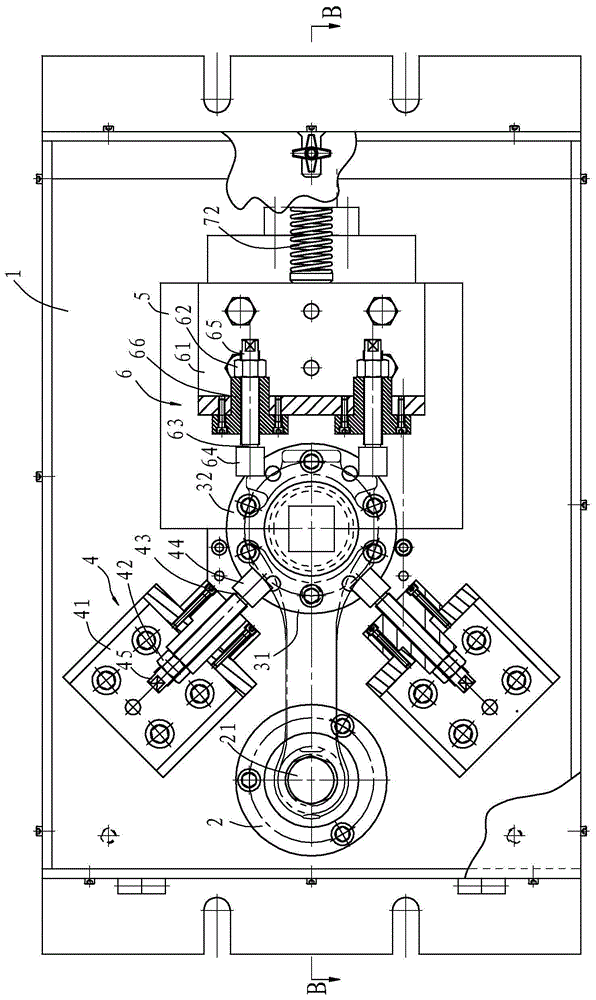

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

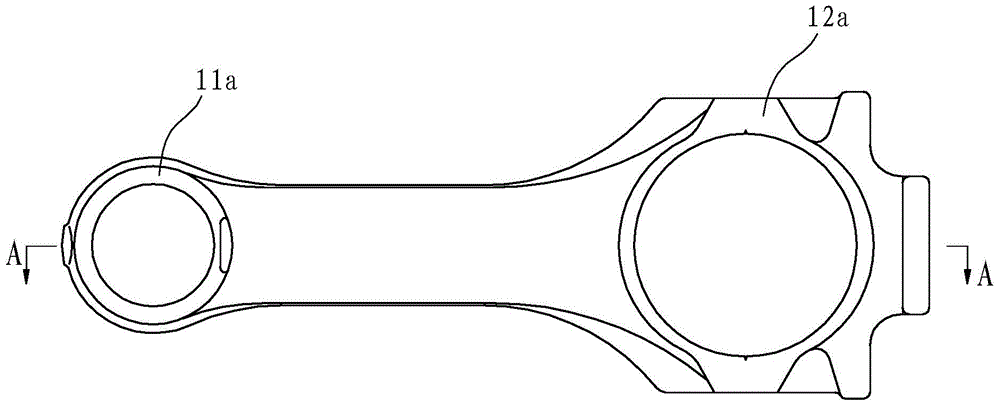

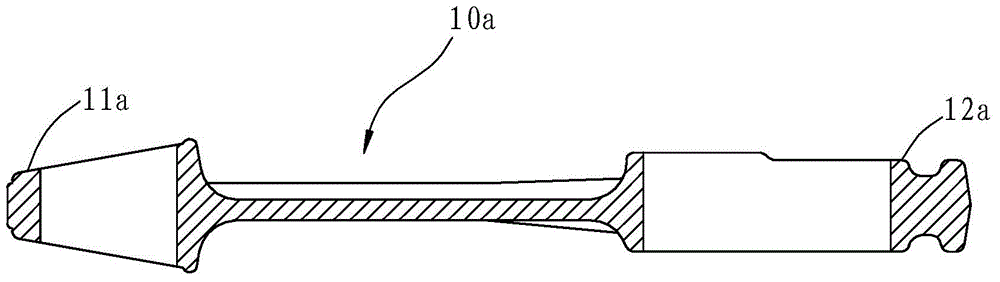

[0043] Such as image 3 with Figure 4 As shown, the clamping device for high-strength tough steel connecting rod cover and connecting rod body embrittlement expansion includes base plate 1, positioning sleeve 2, positioning pin 21, fixed expansion sleeve 31, fixed chuck 4, slide table 5, dynamic expansion Sleeve 32, expansion rod 8, movable chuck 6 and reset mechanism 7, positioning sleeve 2 is longitudinally arranged on the upper end surface of bottom plate 1, positioning pin 21 is arranged on positioning sleeve 2 and has a periphery for the small head 11a of the connecting rod to be sleeved On the other hand, the positioning pin 21 and the positioning sleeve 2 can also be connected in a detachable manner. The fixed expansion sleeve 31 is arranged on the bottom plate 1 and spaced apart from the positioning sleeve 2. There are two fixed cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com