Rubber crushing device

A crushing device and rubber technology, applied in recycling technology, grain processing, mechanical material recycling, etc., can solve the problems of high manufacturing cost, difficult installation and adjustment, complex structure, etc., and achieve low manufacturing cost, simple structure, and smooth feeding and discharging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

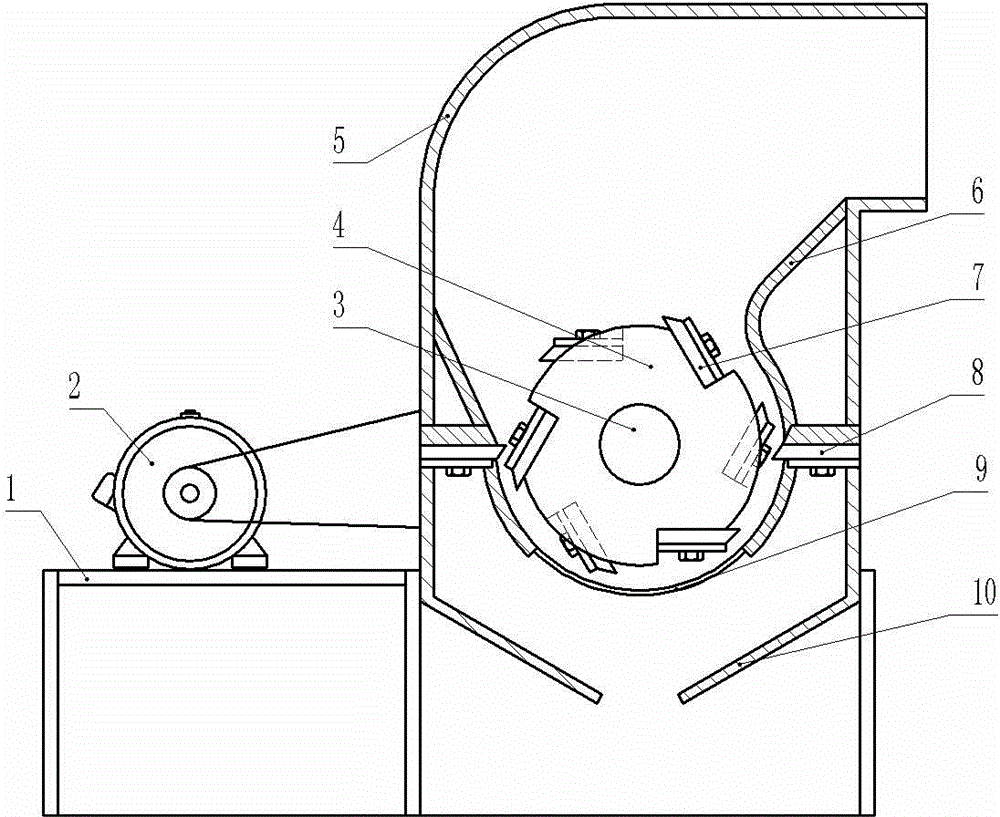

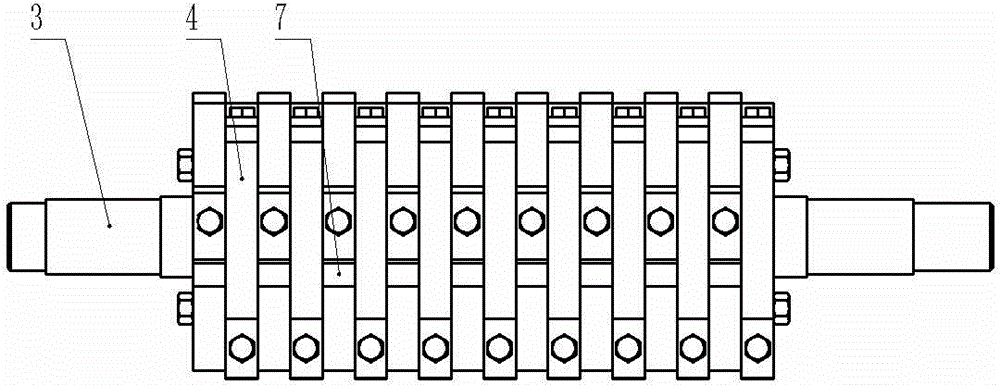

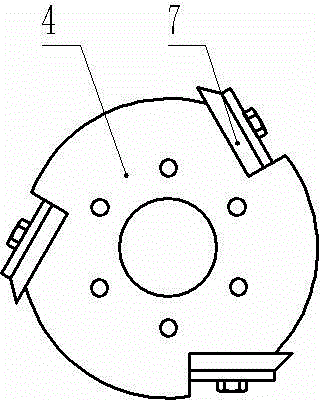

[0014] Such as figure 1 , figure 2 , image 3 The shown rubber pulverizing device includes a housing 5 installed on the support frame 1. The upper part of the housing 5 is provided with a feed port, and the lower part is provided with a discharge port. The rotating crushing knife roller is mounted on the housing 5 through bearings and bearing seats, and the motor 2 mounted on the support frame 1 is connected to the crushing knife roller through a belt drive; the crushing knife roller includes a roller shaft 3 and a roller There are multiple cutterheads 4 on the axis 3, and all the cutterheads 4 are connected by bolts. Each cutterhead 4 has three moving knives 7 distributed along the circumference. The moving knife 7 on the block cutter head 4 is set at an angle of staggered by 60 degrees, and the fixed knife 8 which is sheared and matched with the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com