High-gloss no-weld line light guide plate and forming method thereof

A molding method and non-melting mark technology, applied in the molding of high-gloss non-melting-mark light guide plate and the field of high-gloss non-melting-mark light guide plate products, can solve the problems of poor injection temperature control, difficult injection mold products, etc., to improve quality, enhance The effect of surface scattering performance and high light conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

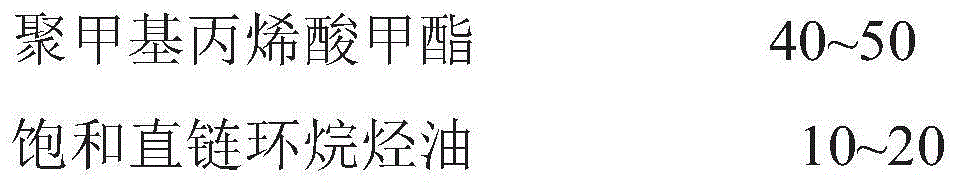

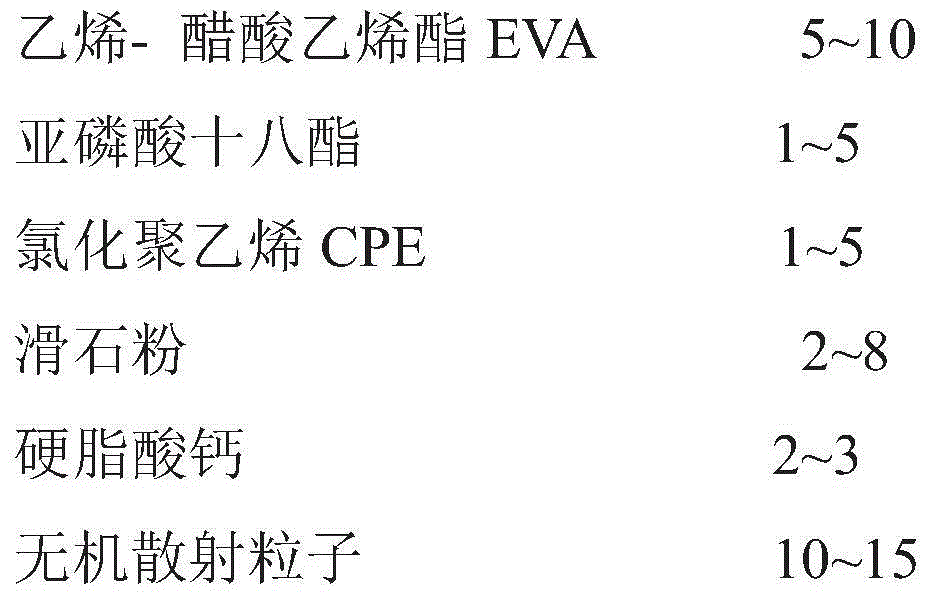

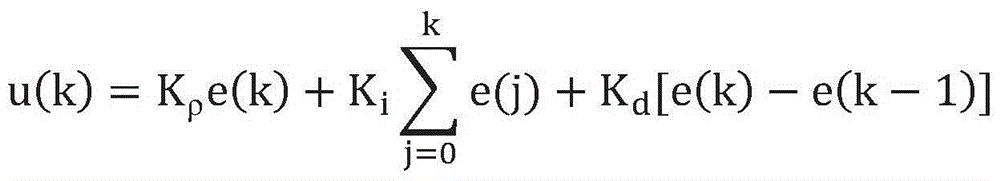

Method used

Image

Examples

Embodiment

[0038] Embodiment: The molding method of the high-gloss non-melting mark light guide plate provided in this embodiment includes the following steps:

[0039] (1) Set up an automatic feeding system to automatically supply injection molding masterbatch to realize the feeding action;

[0040] (2) Set up an injection molding machine, set a temperature control system on the injection molding machine, and control the temperature of the injection mold; after melting the injection masterbatch supplied in step (1), the mold temperature is 30°C to 90°C, and the melt temperature is 210 to 280°C Under the condition of ℃, injection molding is carried out to obtain molded parts;

[0041] (3) The flying cutter milling system is set, and the surface of the molded part is milled under the condition that the rotating speed is 2000r / min and the feed speed is 20mm / min;

[0042] (4) An optical film is provided, and after milling, the optical film is hot-pressed on the upper surface of the injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com