Vehicle Active Differential Transmission Axle

A differential transmission and active technology, applied in the direction of differential transmission, transmission, vehicle parts, etc., can solve the problems of driving comfort that affect the service life, manual locking, unlocking trouble, damage to auto parts, etc., to achieve Improve the driving performance of the vehicle, improve the ride experience, and improve the effect of passing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

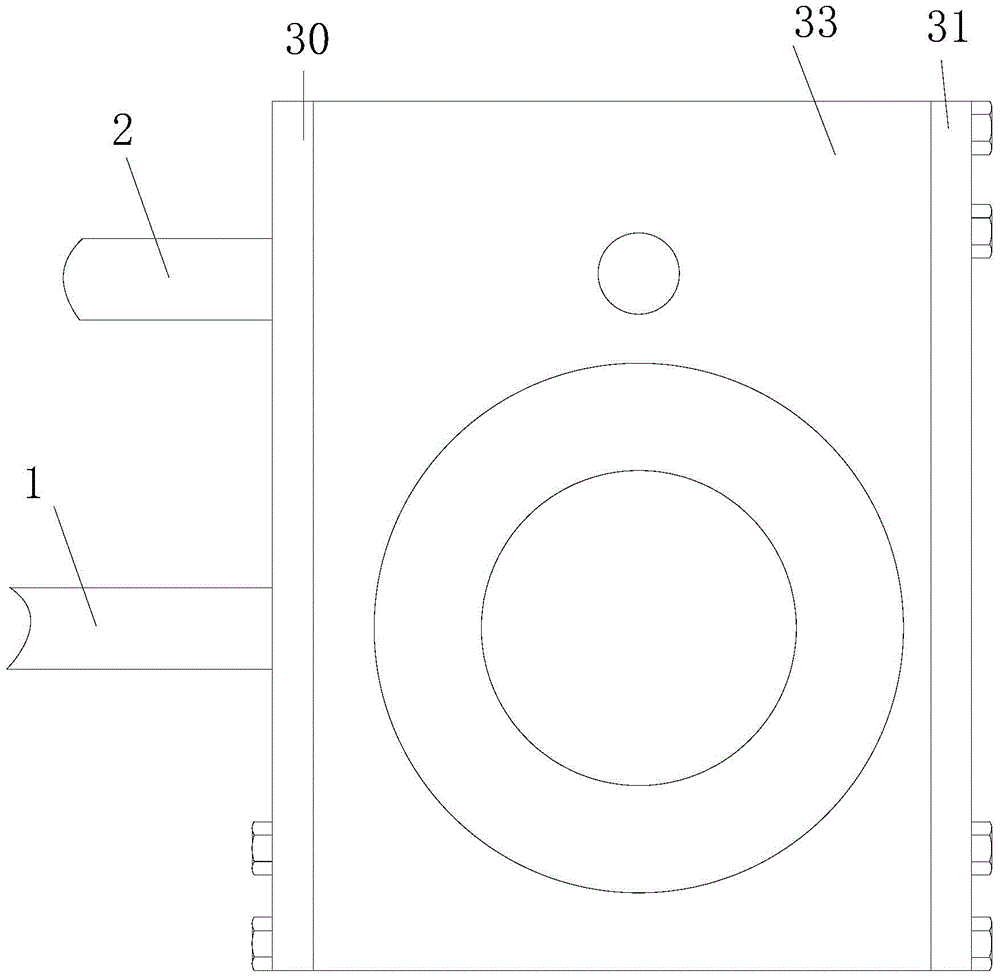

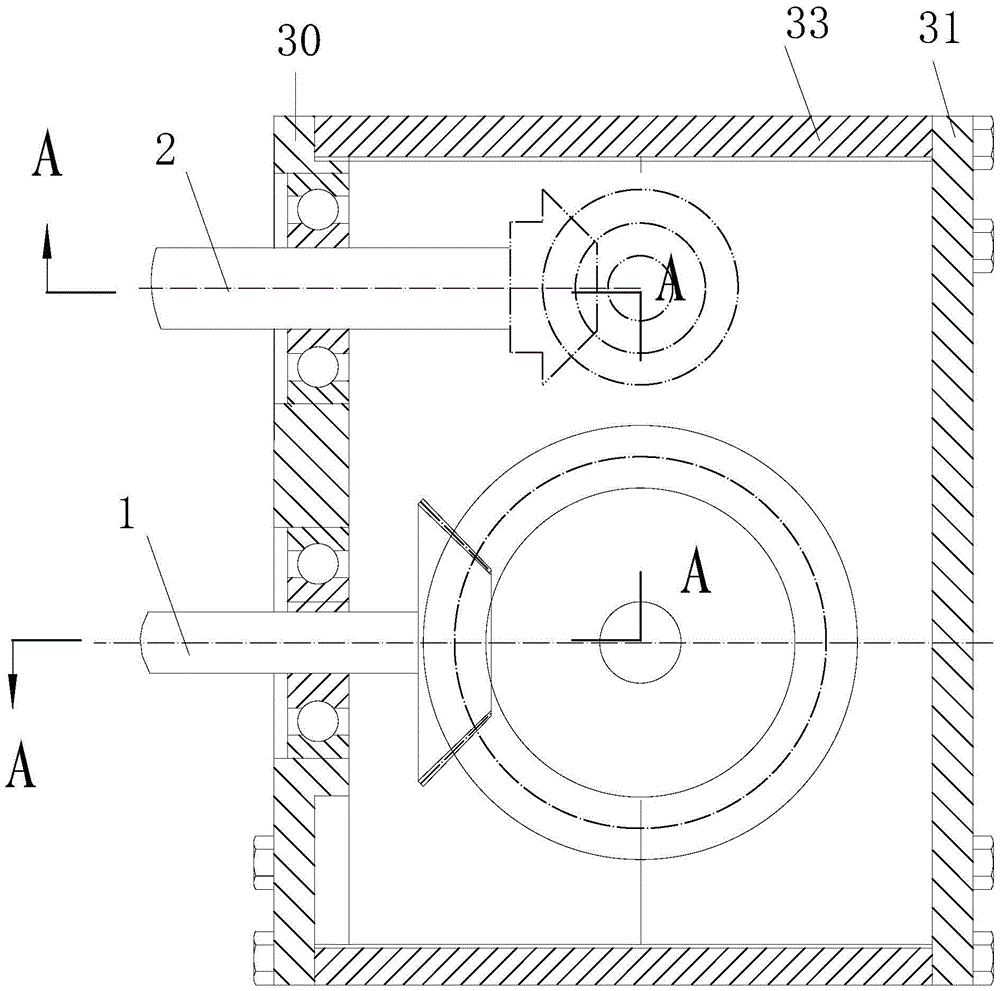

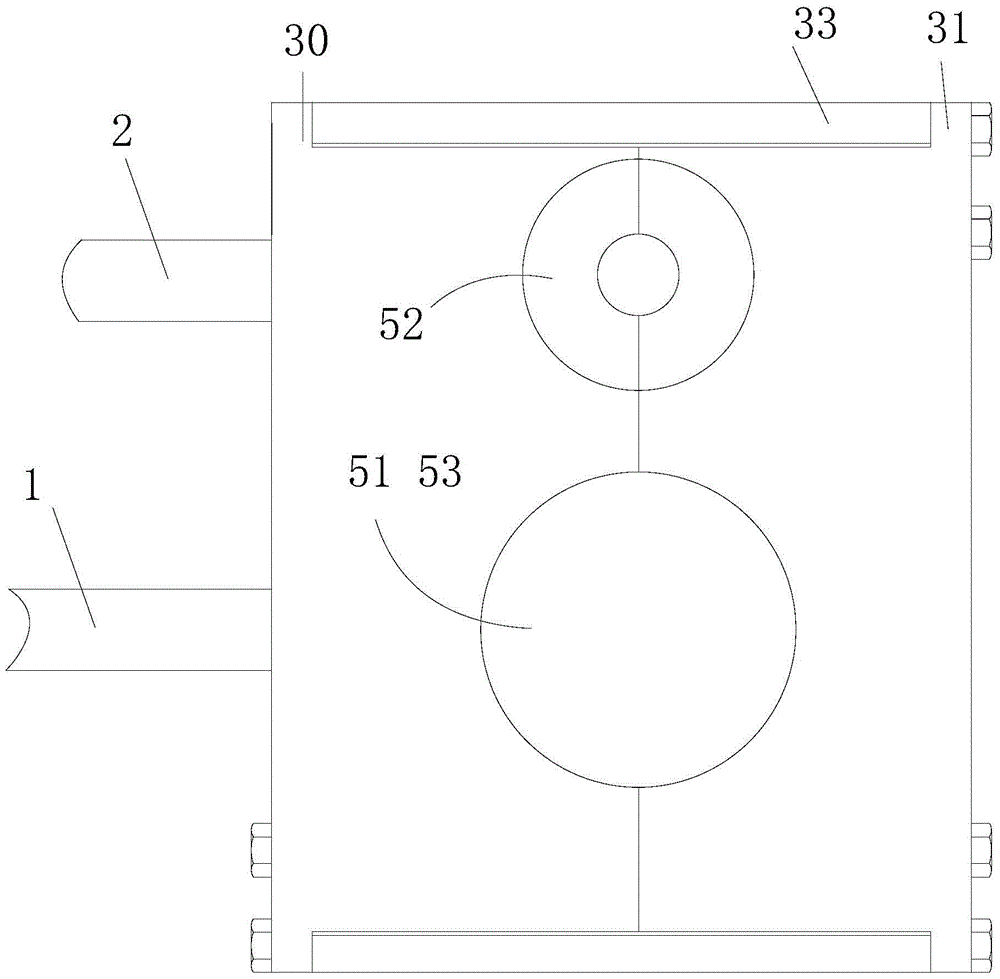

[0018] Such as Figure 1 to Figure 4As shown, an active differential transmission axle for a vehicle includes an axle housing 33, a front fixing plate 30, and a rear fixing plate 31, and two differentials are arranged in the axle housing, namely differential one 34 , Differential 2 35, the front fixing plate 30 and the rear fixing plate 31 are respectively connected with the outer edge of the axle housing 33, the front fixing plate 30 is provided with a first connecting hole 46, a second connecting hole 47, The front fixing plate 30 is respectively provided with a first support plate 36 and a second support plate 37 on both sides of the first connecting hole, and a third support plate 38 and a fourth support plate 39 are provided at the rear fixing plate 31. The first support plate 36 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com