Intelligent load sensing hydraulic system of electric forklift

A technology of load sensing and electric forklifts, applied in fluid pressure actuation system components, fluid pressure actuation devices, lifting devices, etc., can solve the problem of low power efficiency of the hydraulic system, exhaust and noise pollution environment, and increased wear of friction pairs and other problems, to achieve the effects of high loop efficiency, improved reliability, and increased speed regulation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

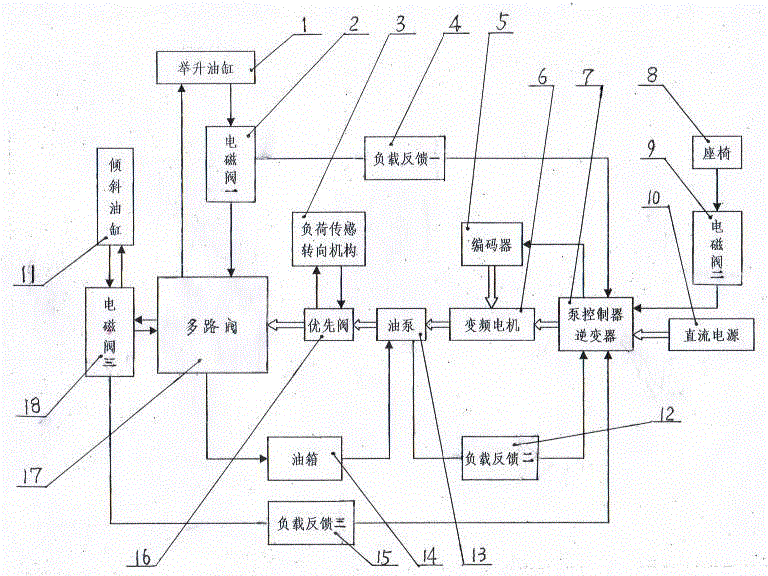

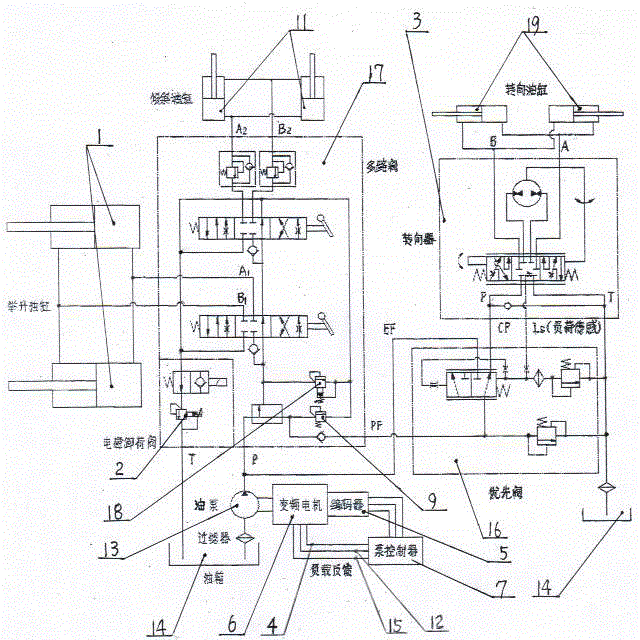

[0010] Examples, see attached figure 1 , the electric forklift intelligent load sensing hydraulic system is composed of seat 8 one-way output connected to solenoid valve two 9, solenoid valve two 9 and DC power supply 10 one-way output connected to pump controller inverter 7, lifting cylinder 1 one-way output Connect the solenoid valve one 2, the one-way output of the solenoid valve one two is connected to the multi-way valve 17, and the multi-way valve 17 is composed of a lift valve, an overload valve, a tilt valve and an oil return valve plate. The one-way output of the multi-way valve 17 is connected to the oil tank 14 and the lifting cylinder 1, the two-way output of the multi-way valve 17 is connected to the solenoid valve three 18, and the two-way output of the solenoid valve three 18 is connected to the tilt cylinder 11 and connected to the load feedback three 15. Solenoid valve 1 2 is connected to load feedback 1 4, load feedback 1 4 unidirectional output is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com