Water-permeable concrete containing river sludge powder and concrete brick

A technology of river silt and water permeability, which is applied in the field of building materials, can solve the problems of poor strength and water permeability, and achieve the effects of low cost, improved strength, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of permeable concrete containing river silt powder is made according to the following steps:

[0036] (1) Take the river silt and first filter it to remove impurities, then dry it in the sun, and finally carbonize it at 300° C. for 30 minutes to obtain the river silt powder;

[0037] (2) weigh out the required river channel silt powder, cement, sand, stone, granular carbon, sodium lignin sulfonate and polycarboxylate water reducing agent for making concrete by weight distribution ratio;

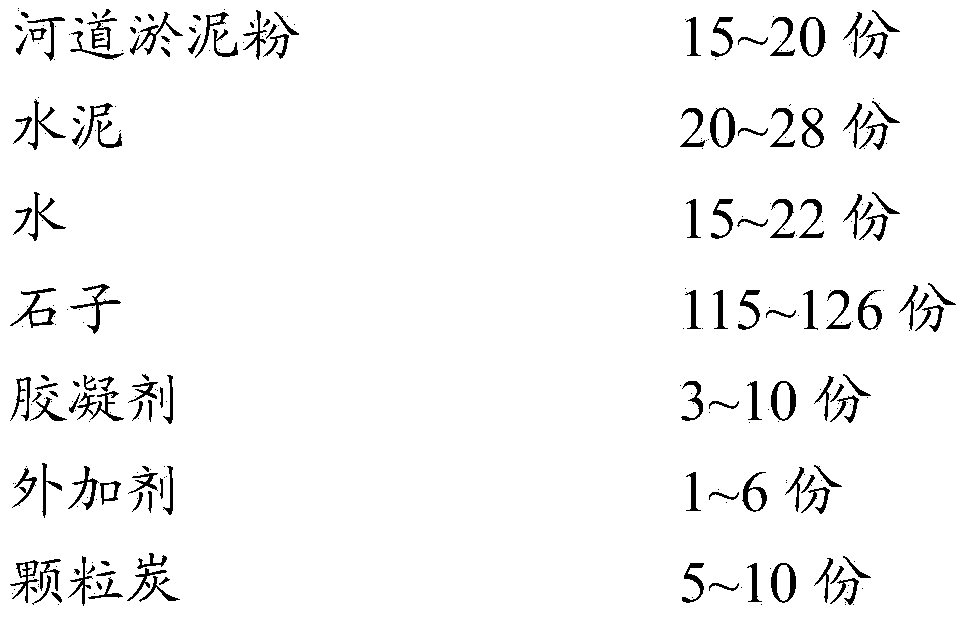

[0038] Its weight distribution ratio is:

[0039]

[0040] (3) Wet the mixer, tools and other contact equipment with water, then pour cement, river sludge powder, granular carbon, sodium lignosulfonate and polycarboxylate water reducer into the mixer and stir evenly, then add an appropriate amount of water, After stirring for 3-5 minutes, add stones to the blender and continue stirring until uniform.

Embodiment 2

[0042] A kind of permeable concrete containing river silt powder is made according to the following steps:

[0043] (1) Take the river silt and filter it to remove impurities, then dry it in the sun, and finally carbonize it at 300°C for 30 minutes to get the river silt powder;

[0044] (2) weigh out the required river channel silt powder, cement, sand, stone, granular carbon, sodium lignin sulfonate and polycarboxylate water reducing agent for making concrete by weight distribution ratio;

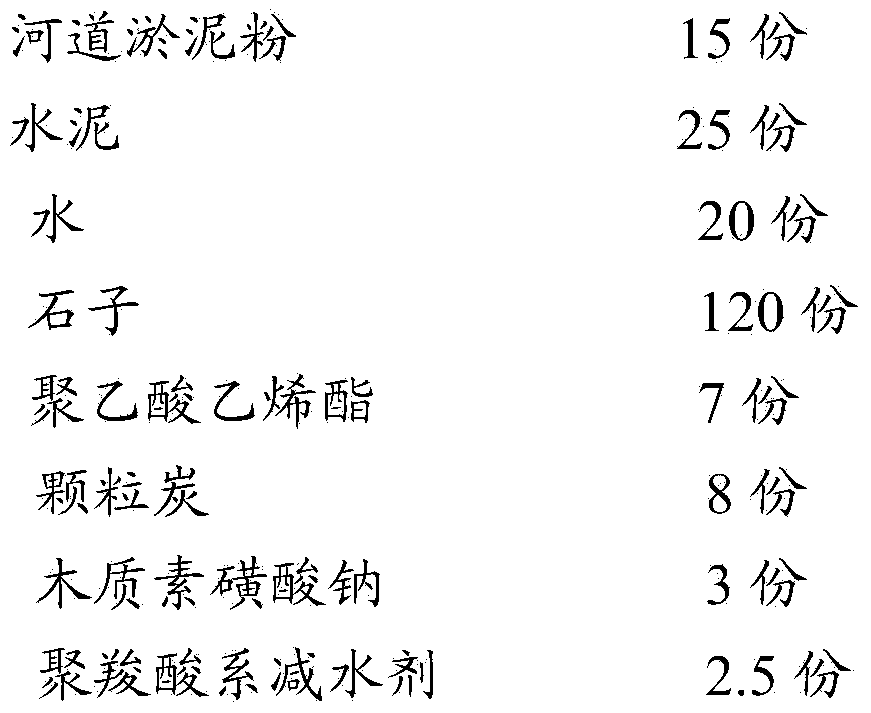

[0045] Its weight distribution ratio is:

[0046]

[0047] (3) Wet the mixer, tools and other contact equipment with water, then pour cement, river sludge powder, granular carbon, sodium lignosulfonate and polycarboxylate water reducer into the mixer and stir evenly, then add an appropriate amount of water, After stirring for 3-5 minutes, add stones to the blender and continue stirring until uniform.

Embodiment 3

[0049] A kind of permeable concrete containing river silt powder is made according to the following steps:

[0050] (1) Take the river silt and first filter it to remove impurities, then dry it in the sun, and finally carbonize it at 300° C. for 30 minutes to obtain the river silt powder;

[0051] (2) weigh out the required river channel silt powder, cement, sand, stone, granular carbon, sodium lignin sulfonate and polycarboxylate water reducing agent for making concrete by weight distribution ratio;

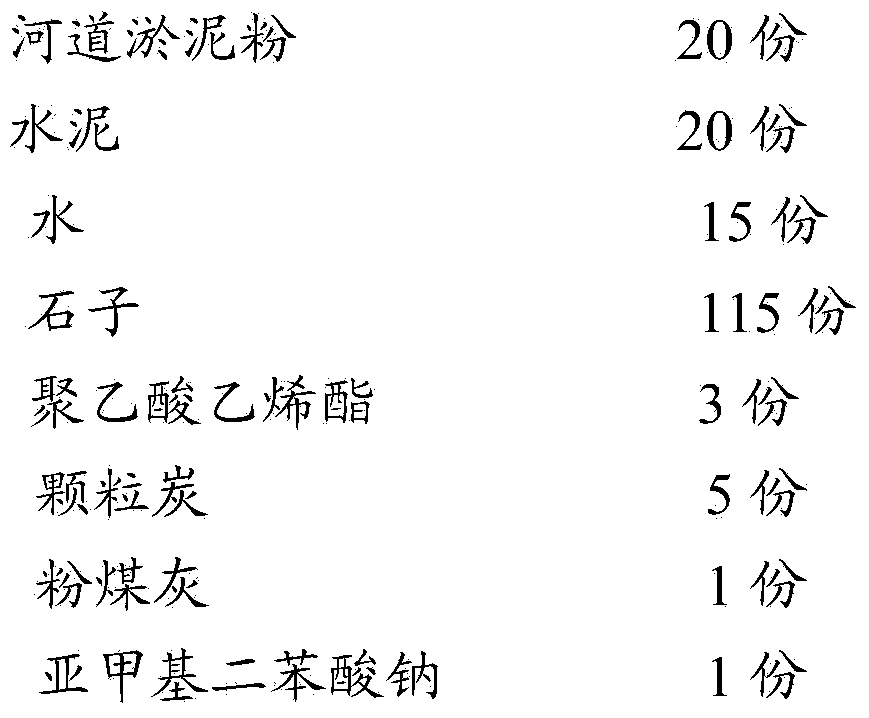

[0052] Its weight distribution ratio is:

[0053]

[0054] (3) Wet the mixer, tools and other contact equipment with water, then pour cement, river sludge powder, granular carbon, sodium lignosulfonate and polycarboxylate water reducer into the mixer and stir evenly, then add an appropriate amount of water, After stirring for 3-5 minutes, add stones to the blender and continue stirring until uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com