Application of a Single Atom Catalyst in Catalytic Hydrogenation of Lignin to Aromatic Compounds

A technology for aromatic compounds and aromatic compounds, applied in catalyst activation/preparation, preparation of organic compounds, catalysts, etc., can solve the problems of harsh reaction conditions, poor atom economy, environmental pollution, etc., achieve low cost, reduce pollution, avoid Effects of environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

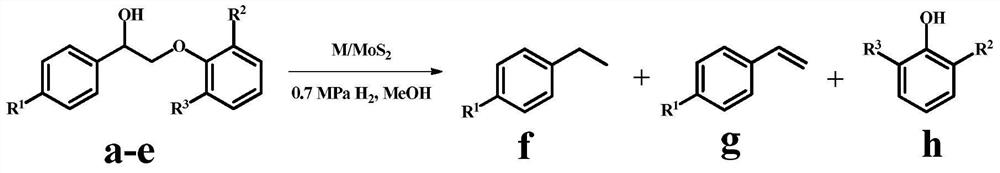

Method used

Image

Examples

Embodiment 1

[0021] single atom M 1 / MoS 2 The specific preparation method of the catalyst (M=Fe, Ni, Ru, Rh, Pd, Pt, Ir) is as follows:

[0022] Monoatomic Ni 1 / MoS 2 Preparation: 0.32 g of ammonium molybdate tetrahydrate, 0.12 g of sulfur powder were added to 57 mL of oleylamine and stirred at room temperature for 10 min, followed by 0.0145 g of NiCl 3 ·6H 2 A solution of O fully dissolved in 3 mL of water was added to the above solution, stirred at room temperature for 1 h, then transferred to a 100 mL stainless steel reaction kettle, and heated to 220 °C for 48 h. Then, centrifugal filtration, washing with ethanol and cyclohexane for several times, until the ligand oleylamine on the catalyst surface was washed away to obtain a black solid, and the collected black solid was vacuum dried for 10 hours.

[0023] Fe 1 , Ru 1 ,Rh 1 ,Pd 1 ,Pt 1 ,Ir 1 / MoS 2 Preparation: Similar to Ni 1 / MoS 2 The preparation process of 0.014g FeCl was used 3 ·6H 2 O, 0.0065g RuCl 3 ·H 2 O, ...

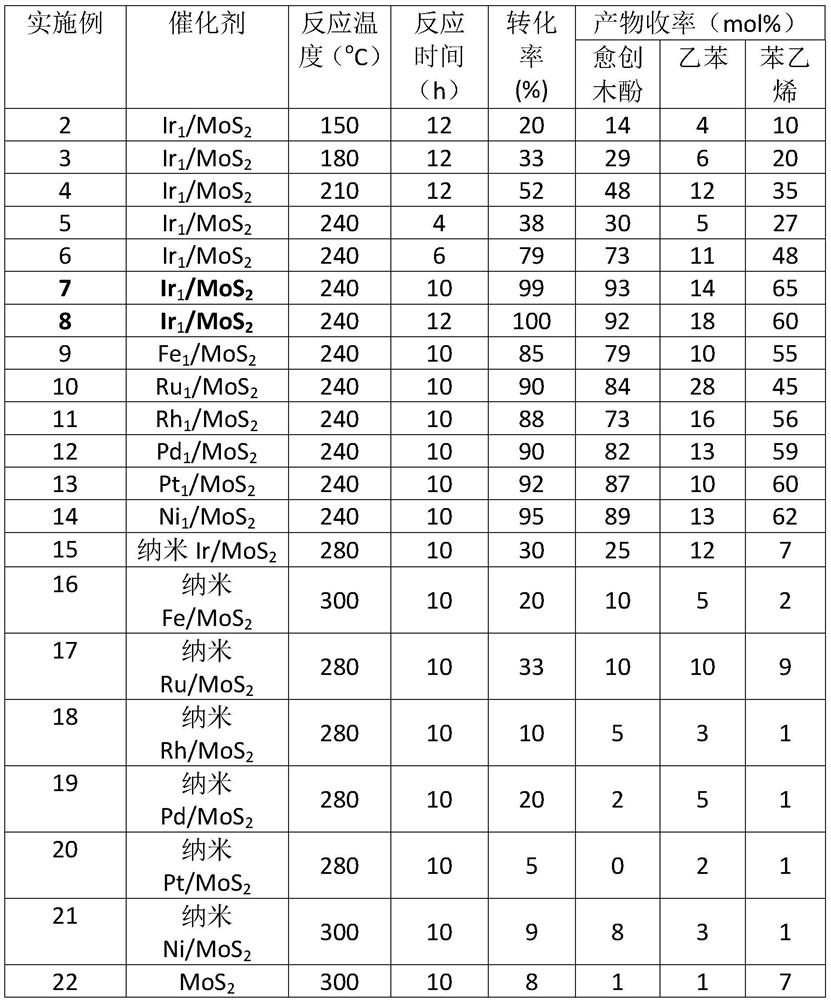

Embodiment 2-22

[0027] Example 2-22 Single Atom M 1 / MoS 2 The catalyst catalyzes the depolymerization of the lignin model molecule 2-(2-methoxyphenoxy)-1-phenylethanol: 100 mg of the lignin model molecule was mixed with monoatomic M / MoS in a reaction kettle 220 mg of the catalyst was dissolved in 30 mL of methanol, replaced with hydrogen for six times, and the reactor was sealed at 0.7 MPa and heated to 150°C-240°C, and the reaction was stirred at a speed of 750 rpm for 4h-12h. After the reaction was completed, the temperature was lowered to room temperature, and the supernatant was filtered and sampled for analysis. The qualitative analysis of the product was achieved by GC-MS combined technology and standard sample control, and the quantitative analysis was achieved by gas chromatography internal standard method. The reaction results are shown in Table 1.

[0028] Table 1 Single atom M under different conditions 1 / MoS 2 Catalysts and Nanocatalysts M / MoS 2 Catalytic results of depoly...

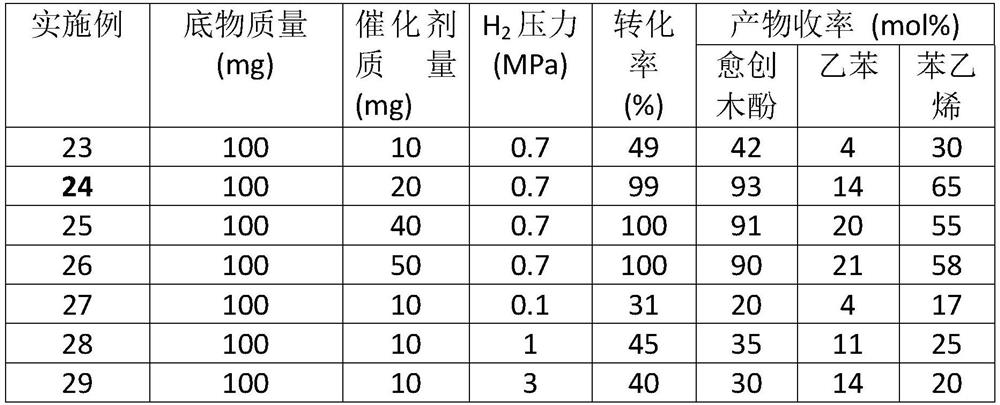

Embodiment 23-29

[0032] Ir 1 / MoS 2 Catalytic depolymerization of lignin model molecule 2-(2-methoxyphenoxy)-1-phenylethanol under different conditions: a certain mass of lignin model molecule was combined with the single-atom catalyst Ir in a reactor 1 / MoS 2 They were dissolved in 30 mL of different solvents, replaced with hydrogen for five times, and then filled with hydrogen to the set pressure. After the reaction was completed, the temperature was lowered to room temperature, and the supernatant was filtered and sampled for analysis. The qualitative analysis of the product was achieved by GC-MS combined technology and standard sample control, and the quantitative analysis was achieved by gas chromatography internal standard method. The reaction results are shown in Table 2.

[0033] Table 2 Single-atom catalyst Ir under different conditions 1 / MoS 2 Catalytic results of depolymerization of lignin model molecule 2-(2-methoxyphenoxy)-1-phenylethanol

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com