Method for industrialized continuous production of hydroxyacetonitrile

A technology for hydroxyacetonitrile and products, which is applied in the field of continuous production of hydroxyacetonitrile, can solve the problems of easy polymerization or decomposition of products, reduce the conversion rate of raw materials, and reduce product quality, so as to avoid product accumulation and multiple side reactions, avoid reaction interference, reduce The effect of exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

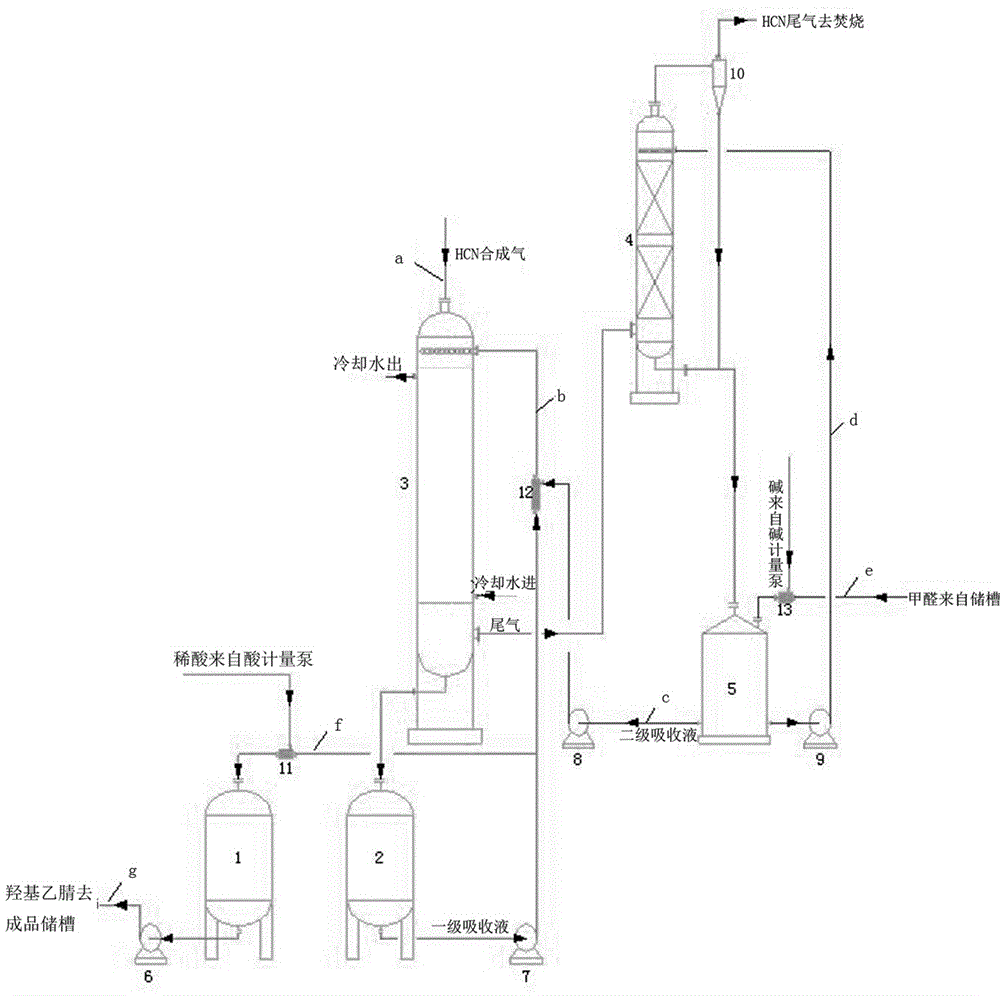

[0054] Add 10m in the secondary circulation tank 5 3 formaldehyde (concentration is 10%wt), and add alkali to adjust the pH value to 6.0-6.5. The formaldehyde that adjusts the pH value in the secondary circulation tank 5 is transferred to 2m 3 In the primary circulation tank 2, start the primary reaction circulation pump 7 and the secondary reaction circulation pump 9 to beat the circulation. At the same time, HCN gas (flow velocity 22m / s) is passed into the primary and secondary reactors 3 and 4. And by adjusting the amount of cooling water so that the temperature of the liquid during the reaction is 15-20 ° C. Monitor the residual value of formaldehyde in the primary circulation tank 2 at any time, and when the residual value of formaldehyde reaches the required value (formaldehyde cannot be detected), qualified hydroxyacetonitrile is obtained.

[0055]Then, the formaldehyde feeding pump 8 is turned on to add the formaldehyde (or secondary absorption liquid) in the second...

Embodiment 2

[0058] Add 5m to the secondary circulation tank 5 3 formaldehyde (concentration is 37%wt), and add alkali to adjust the pH value to 6.5-7.0. The formaldehyde that adjusts the pH value in the secondary circulation tank 5 is transferred to 2m 3 In the primary circulation tank 2, start the primary reaction circulation pump 7 and the secondary reaction circulation pump 9 to beat the circulation. At the same time, HCN gas (flow velocity 22m / s) is passed into the primary and secondary reactors 3 and 4. And by adjusting the amount of cooling water so that the temperature of the liquid during the reaction is 15-20 ° C. Monitor the residual value of formaldehyde in the primary circulation tank 2 at any time, and when the residual value of formaldehyde reaches the required value (formaldehyde cannot be detected), qualified hydroxyacetonitrile is obtained.

[0059] Then, the formaldehyde feeding pump 8 is turned on to add the formaldehyde (or secondary absorption liquid) in the second...

Embodiment 3

[0062] Add 5m to the secondary circulation tank 5 3 (concentration is 50%wt) formaldehyde, and add alkali to adjust the pH value to 6.5-7.0. The formaldehyde that adjusts the pH value in the secondary circulation tank 5 is transferred to 2m 3 In the primary circulation tank 2, start the primary reaction circulation pump 7 and the secondary reaction circulation pump 9 to beat the circulation. At the same time, HCN gas (flow velocity 22m / s) is passed into the primary and secondary reactors 3 and 4. And by adjusting the amount of cooling water so that the temperature of the liquid during the reaction is 15-20 ° C. Monitor the residual value of formaldehyde in the primary circulation tank 2 at any time, and when the residual value of formaldehyde reaches the required value (formaldehyde cannot be detected), qualified hydroxyacetonitrile is obtained.

[0063] Then, turn on the formaldehyde feeding pump 8 to add formaldehyde (or the secondary absorption liquid) in the secondary c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com