Hyperbranched epoxy resin as well as preparation method and application thereof in coating

A technology of epoxy resin and epoxy equivalent, applied in the direction of epoxy resin coating, coating, etc., can solve the problems of unfavorable application, inability to effectively form high cross-linking density paint film, single epoxy functional group, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

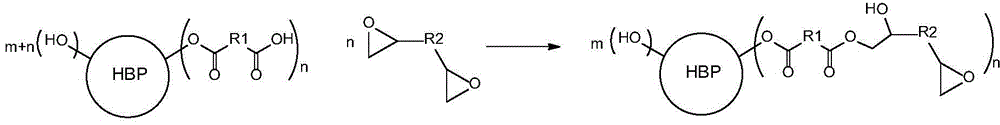

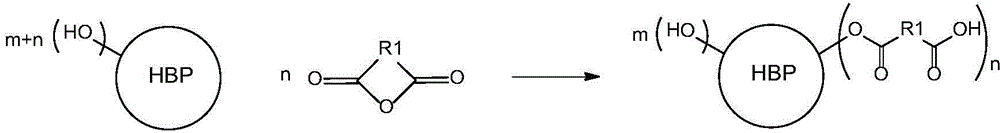

Method used

Image

Examples

Embodiment 1

[0084] Boltorn H4001-HHPA-E188-30% Synthesis (30% of the hydroxyl groups of hyperbranched hydroxyl polyester Boltorn H4001 are replaced by epoxy groups)

[0085] (1) Add Boltorn H4001 solution containing 1 mole of hydroxyl groups and 0.3 mole of hexahydrophthalic anhydride to a four-necked flask with a stirrer, a thermometer and a condenser, start stirring and heat up to 130°C, and 130℃ insulation reaction;

[0086] (2) Detect the acid value of the solution after reacting for 1 hour, and then detect the acid value of the solution every 30 minutes until the acid value of the solution is stable and does not continue to decline. Then add 0.3 mole of epoxy resin E188 (bisphenol A type epoxy resin molecular weight is 376) and account for the catalyst DBTDL of 0.1wt% of total reactant, in 140 ℃ insulation reaction, after 4 hours, detect solution acid value every 1 hour until the acid value of the solution is stabilized in the range of 0-5mgKOH / g, which is the end point of the react...

Embodiment 2

[0089] Boltorn H4001-HHPA-E188-40% Synthesis (40% of the hydroxyl groups of hyperbranched hydroxyl polyester Boltorn H4001 are replaced by epoxy groups)

[0090] (1) Add Boltorn H4001 solution containing 1 mole of hydroxyl groups and 0.4 mole of hexahydrophthalic anhydride to a four-necked flask with a stirrer, a thermometer and a condenser, start stirring and heat up to 130°C, and 130℃ insulation reaction;

[0091] (2) Detect the acid value of the solution after reacting for 1 hour, and then detect the acid value of the solution every 30 minutes until the acid value of the solution is stable and does not continue to decline. Then add 0.4 mole of epoxy resin E188 (bisphenol A type epoxy resin, molecular weight is 376) and account for the catalyzer DBTDL of 0.1wt% of total reactant, in 140 ℃ of insulation reactions, after 4 hours, detect solution acid every 1 hour value until the acid value of the solution reaches a stable range of 0-5mgKOH / g, which is the end point of the rea...

Embodiment 3

[0094] Boltorn H4001-HHPA-E140-10% Synthesis (10% of the hydroxyl groups of hyperbranched hydroxyl polyester Boltorn H4001 are replaced by epoxy groups)

[0095](1) Add Boltorn H4001 solution containing 1 mole of hydroxyl groups and 0.1 mole of hexahydrophthalic anhydride to a four-necked flask with a stirrer, thermometer and condenser, start stirring and heat up to 130°C, 130℃ insulation reaction;

[0096] (2) Detect the acid value of the solution after reacting for 1 hour, and then detect the acid value of the solution every 30 minutes until the acid value of the solution is stable and does not continue to decline. Then add 0.1 mole of epoxy resin E140 (aliphatic epoxy resin, molecular weight is 280) and account for the catalyzer DBTDL of 0.1wt% of total reactant, in 140 ℃ of insulation reactions, detect solution acid value every 1 hour after 4 hours, Until the acid value of the solution is stabilized in the range of 0-5mgKOH / g, it is the end point of the reaction. Add dilu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com