Potassium amino polymer strong-inhibition anti-collapse drilling fluid for argillaceous siltstone stratum

A polymer and siltstone technology, applied in the field of drilling fluid, can solve problems such as wellbore instability, increased cost, and extended drilling cycle, and achieve the effects of stabilizing the wellbore, reducing water absorption tendency, and preventing water from entering the formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

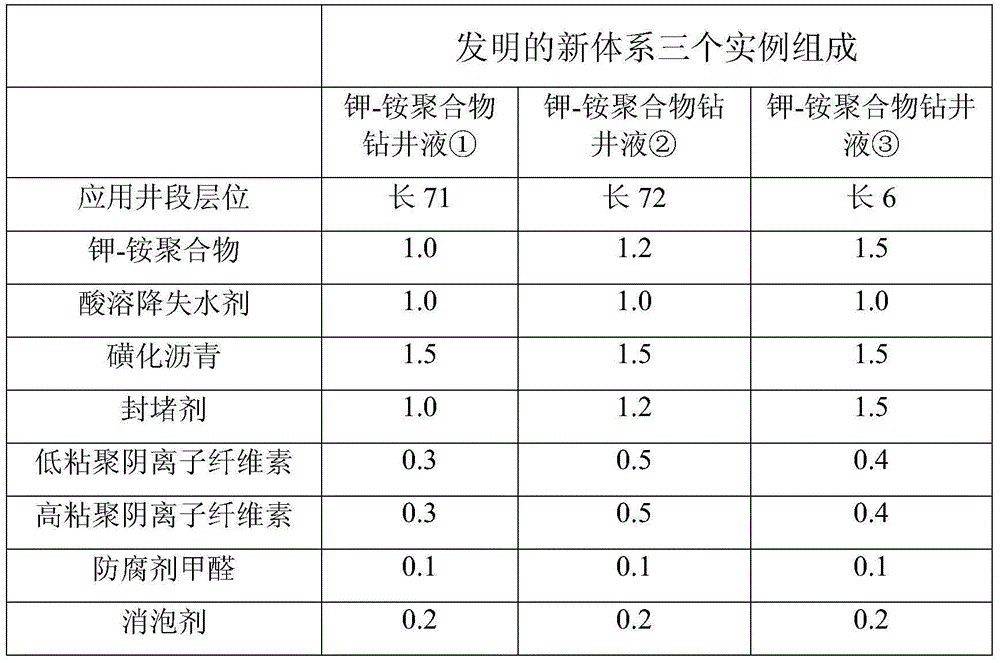

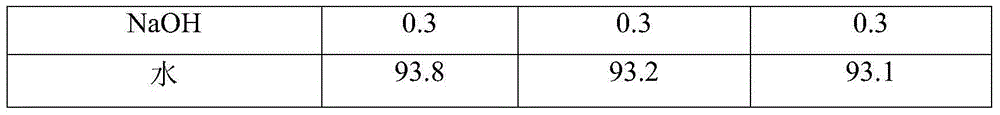

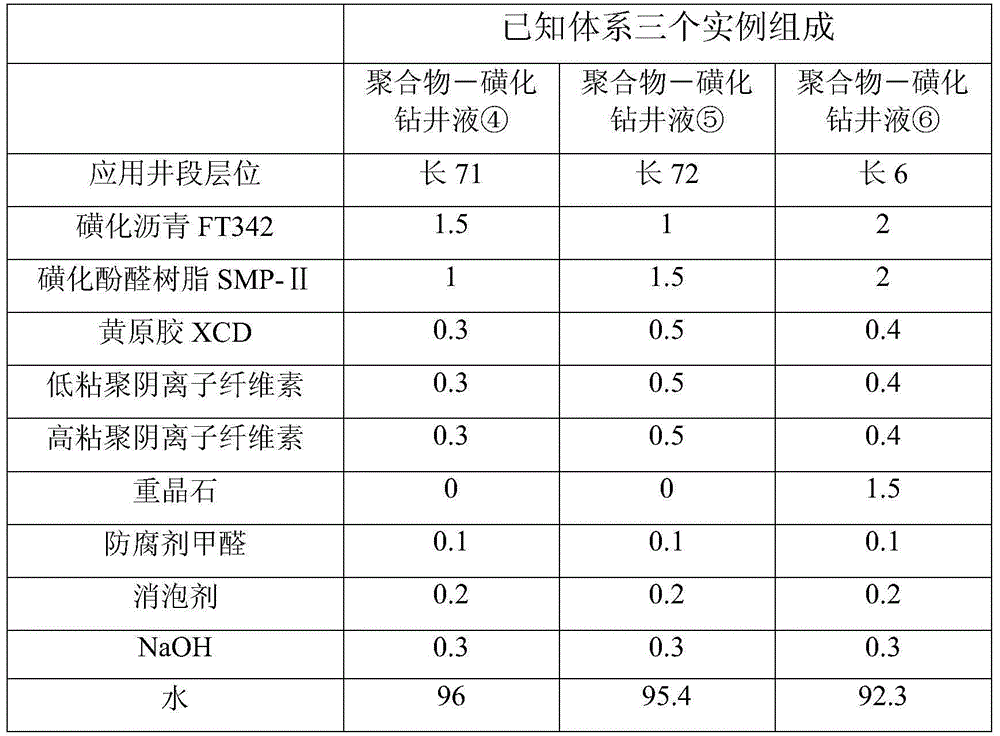

Examples

Embodiment 2

[0043]The organic amine strong inhibition anti-slump drilling fluid is prepared from the following components (weight percentage): potassium-ammonium polymer weight ratio 1.3%, acid-soluble fluid loss reducer G310-SJS weight ratio 1.2%, sulfonated asphalt weight ratio 1.5% , The weight ratio of plugging agent is 1.5%, the weight ratio of high-viscosity polyanionic cellulose PAC-HV (Xianyang Chemical Factory) is 0.3%, the weight ratio of low-viscosity polyanionic cellulose PAC-LV (Xianyang Chemical Factory) is 0.3%, Add a certain amount of weighting agent according to actual needs, the pH value is between 9-10, and the balance is water.

Embodiment 3

[0045] The organic amine strong inhibition anti-slump drilling fluid is prepared from the following components (weight percent): potassium-ammonium polymer weight ratio 1.4%, acid-soluble fluid loss reducer G310-SJS weight ratio 1.2%, sulfonated asphalt weight ratio 1.5%, The weight ratio of the plugging agent is 2.0%, the weight ratio of high-viscosity polyanionic cellulose PAC-HV (Xianyang Chemical Factory) is 0.3%, and the weight ratio of low-viscosity polyanionic cellulose PAC-LV (Xianyang Chemical Factory) is 0.3%. The actual need to add a certain amount of weighting agent, the pH value is between 9-10, and the balance is water.

[0046] In the application of examples 2 and 3, the system also exhibits good anti-slump inhibition, lubrication, low solid phase, and good operation at high ROP, with the average ROP at 4.5 m / h. During the drilling process, the wellbore was good, and the downhole was always normal. After drilling, the electrical measurement went smoothly, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com