High-dispersion steel fiber reinforced concrete and construction technology thereof

A technology of steel fiber concrete and construction technology, which is applied in the field of building construction, can solve the problems of no reinforcement, local strength weakening, etc., and achieve the effect of overcoming adverse effects, good workability, and meeting the needs of on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

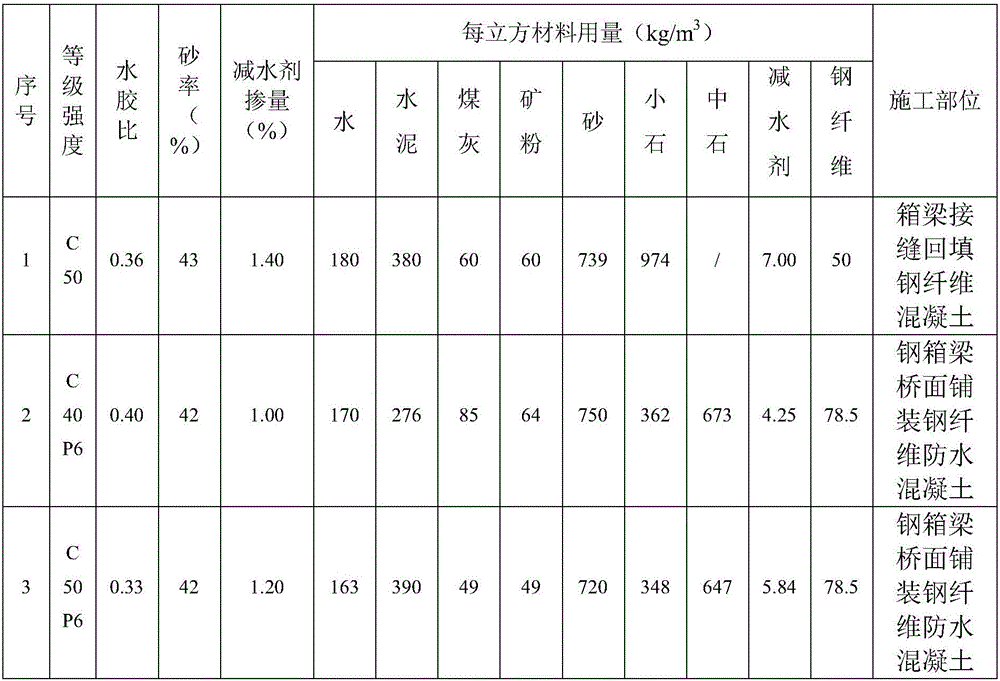

[0019] Specifically illustrate a kind of high-dispersion steel fiber concrete provided by the present invention, the formula and proportion of the steel fiber material concrete according to weight parts, wherein cement is 276~390 parts, water is 163~180 parts, sand is 720~ 739 parts, 974-1035 parts of stones, 49-85 parts of coal powder, 49-64 parts of mineral powder, 4.25-7.00 parts of water reducing agent and 50-78.5 parts of steel fiber. In this embodiment, the steel fiber It is shear-type wavy fiber with a length of 25-50 mm and a diameter of 0.3-0.8 mm, see Table 1 for content.

Embodiment 2

[0021] A high-dispersion steel fiber concrete provided in this example is improved on the basis of Example 1. According to the formula and proportion by weight, 276 parts of cement, 170 parts of water, and 750 parts of sand , 673 parts of stones with a particle size of 10-20mm, 362 parts of stones with a particle size of 5-10mm, 85 parts of coal powder, 64 parts of mineral powder, 4.25 parts of water reducing agent and 78.5 parts of steel fiber.

Embodiment 3

[0023] A high-dispersion steel fiber concrete provided in this embodiment is improved on the basis of Example 1. The steel fiber material concrete is formulated and proportioned according to parts by weight, wherein the cement is 390 parts and the water is 163 parts. 720 parts of sand, 647 parts of stones with a particle size of 10-20mm, 348 parts of stones with a particle size of 5-10mm, 49 parts of coal powder, 49 parts of mineral powder, 5.84 parts of water reducing agent and 78.5 parts of steel fiber .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com