Continuous paving construction technology of cement concrete bridge floor and steel bridge floor

A technology of cement concrete and construction technology, which is applied to the direction of on-site paved coagulation pavement, bridges, bridge parts, etc., which can solve the problem that the paving operation cannot be carried out continuously, the flatness of the road surface is affected, and the number of lift-offs of the paver screed is too high And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0122] The span bridge is paved and constructed by continuous paving of cement concrete deck and steel bridge deck. The whole bridge is 485m long and 25m wide. The deck of the cement concrete bridge adopts the traditional asphalt concrete surface; Construction technology of continuous paving of bridge deck.

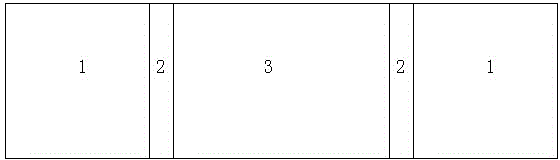

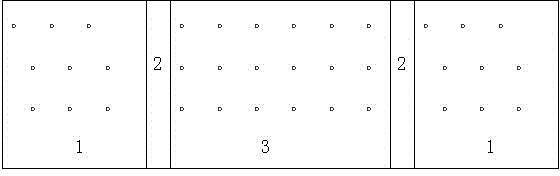

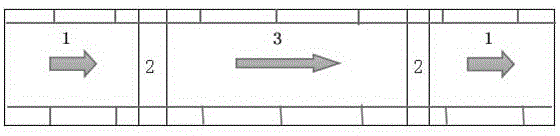

[0123] figure 1 1 represents the traditional asphalt concrete on the cement concrete bridge deck; 2 represents the expansion joint; 3 represents the asphalt mastic macadam mixture on the steel bridge deck.

[0124] 1. Preparatory work before construction

[0125] (1) Bridge deck preparation and sticky layer oil construction

[0126] Before laying the asphalt mixture, clean the bridge deck free of any loose stones, dust and impurities. Asphalt spreader is used to spray sticky layer oil to ensure continuous paving operation;

[0127] (2) Construction stakeout

[0128] 1. Elevation re-measurement

[0129]The surveyors will conduct a comprehensive re-measurement of the...

Embodiment 2

[0179] The span bridge is paved and constructed by continuous paving of cement concrete deck and steel bridge deck. The whole bridge is 485m long and 25m wide. The deck of the cement concrete bridge adopts the traditional asphalt concrete surface; Construction technology of continuous paving of bridge deck.

[0180] Calculation based on the design drawings: the cement concrete bridge deck is 194m long; 25m wide; the paving thickness of the cement concrete bridge deck is 10cm; traditional asphalt mixture is required for 485m 3 ; The steel bridge deck is 291m long; 25m wide; the paving thickness of the steel bridge deck is 7cm; 509.25m of asphalt mastic gravel mixture is required 3 ;

[0181] 1. Preparatory work before construction

[0182] The bridge deck has been cleaned without any loose stones, dust and impurities; the sticky layer oil on the bridge deck has been sprayed to ensure the continuous completion of paving operations.

[0183] Height re-measurement and measurem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pull | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com