Pump suction reverse circulation pile foundation construction device and method

A pump suction reverse circulation and construction device technology, which is applied in infrastructure engineering, sheet pile walls, earthwork drilling and other directions, can solve the problems of low hole forming efficiency, large power consumption, and the need to seal the pump suction loop. The effect of shortening the pumping loop, increasing the suction and reducing the power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

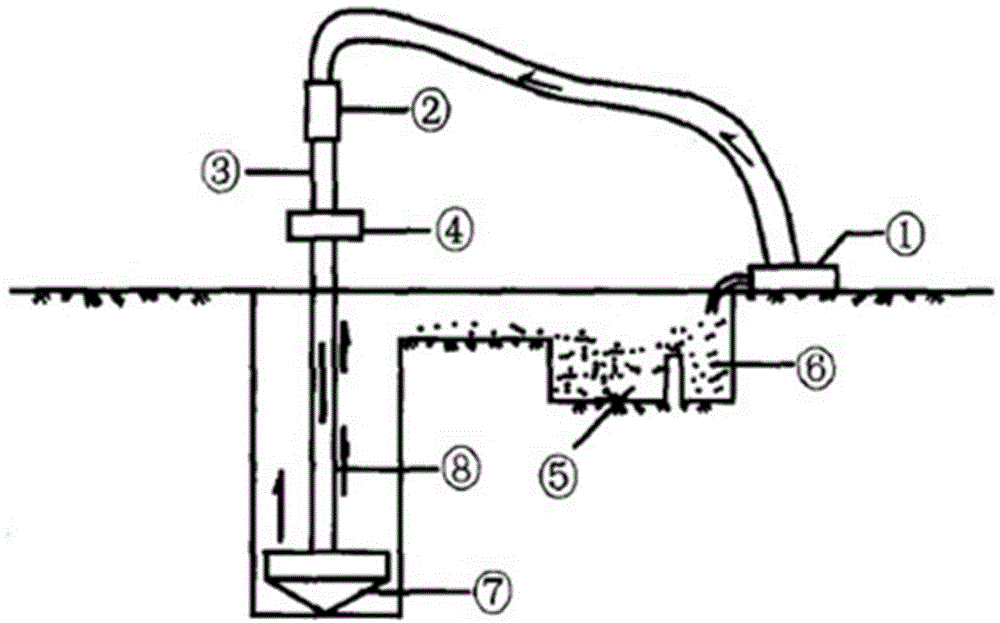

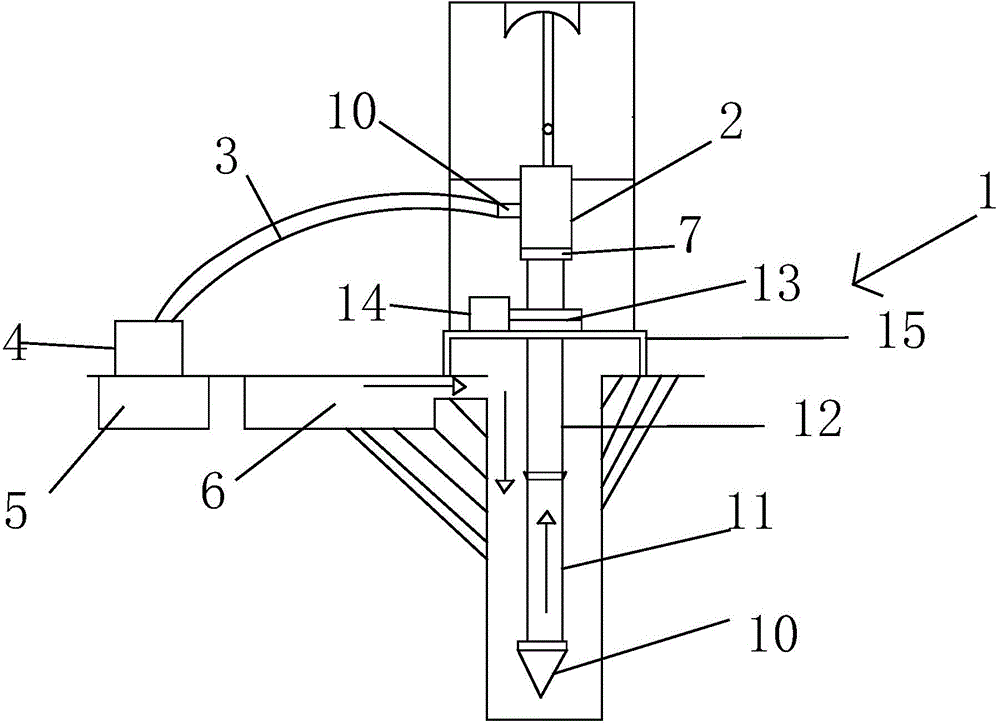

[0030] Combine below figure 2 The pump suction reverse circulation pile foundation construction device of the present invention will be described in detail.

[0031] A pump-suction reverse-circulation pile foundation construction device, which is suitable for the construction of bored piles in deep silty soil, including a rotary drilling rig 1, a reverse-circulation gravel pump 2, a slag suction hose 3, Mud purification device 4, sedimentation tank 5 and circulation tank 6; rotary drilling rig 1 includes drill bit 10, drill pipe 11, transmission rod 12, rotary disc 13, hydraulic motor 14 and base 15 arranged on the top of the pile foundation. The through hole for the transmission rod 12 to pass through, the hydraulic motor 14 is arranged on the base 15, the bottom end of the drill bit 10 and the drill rod 11 are fixedly connected by a flange, and the top end of the drill rod 11 and the bottom end of the transmission rod 12 are fixed by a flange connection, the top of the tra...

Embodiment 2

[0035] Continue to combine below figure 2 The method of using the pump suction reverse circulation construction device to carry out bored pile foundation construction is described in detail. The construction method of bored pile foundation comprises the following steps:

[0036] Step 1. Provide a pump suction reverse circulation pile foundation construction device, make preparations for commissioning, and set up a mud circulation system at the same time.

[0037] The pump suction reverse circulation pile foundation construction device includes a rotary drilling rig 1, a reverse circulation gravel pump 2, a slag suction hose 3, a mud purification device 4, a sedimentation tank 5 and a circulation tank 6 connected in sequence; the rotary drilling rig 1 includes a drill bit 10, a drill Rod 11, transmission rod 12, rotating disk 13, hydraulic motor 14 and the base 15 that is arranged on the pile foundation top, the base 15 is provided with the through hole that passes through fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com