Drilling detecting integrated system and method for overlying strata fracture detection

A fissure and overlying rock technology, which is applied in the field of integrated drilling and measuring systems for overlying fissure detection, can solve problems such as overlying fissures cannot be detected at the same time, the reliability of sealing holes cannot be artificially verified, measurement errors, etc., and is easy to popularize and use. , The effect of improving the reliability of sealing holes and improving the detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

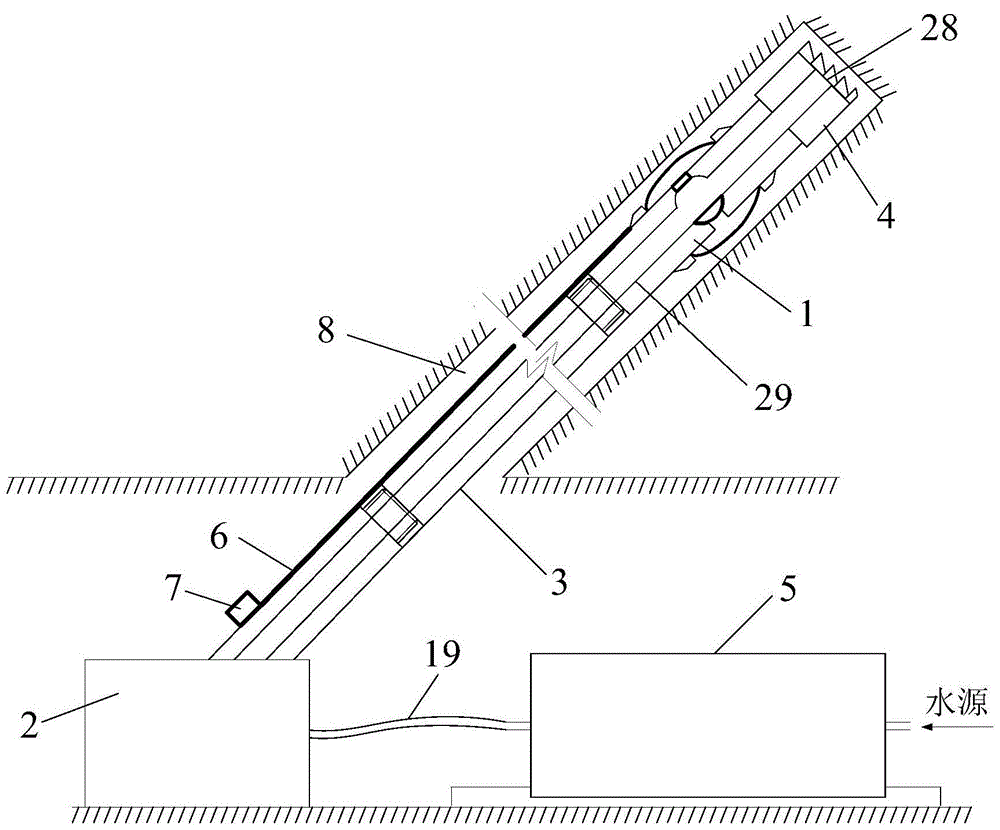

[0036] Such as Figure 1-Figure 9 As shown, an integrated drilling and measuring system for overlying rock fracture detection includes a probe 1, a drilling device and a control device.

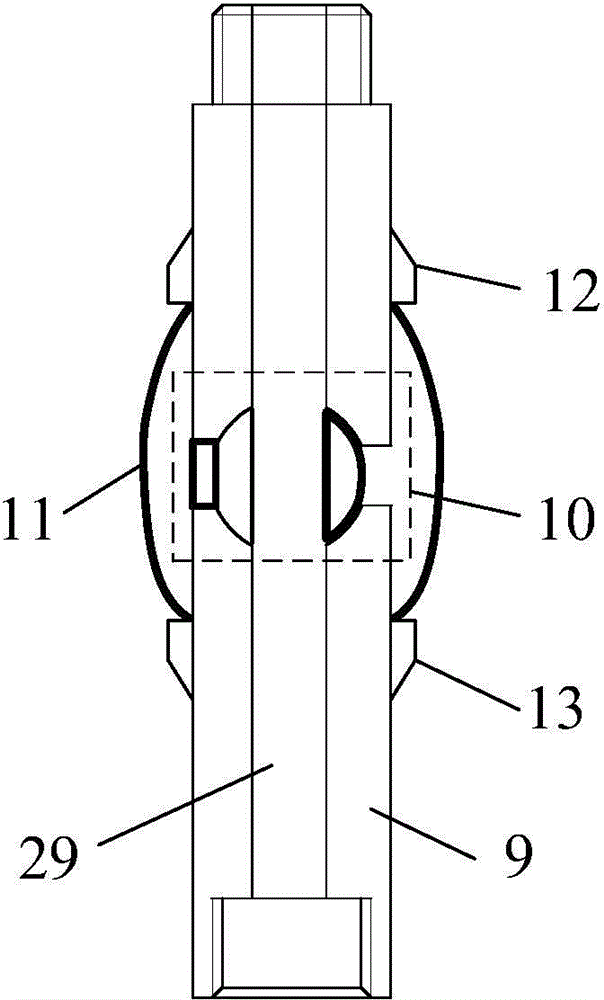

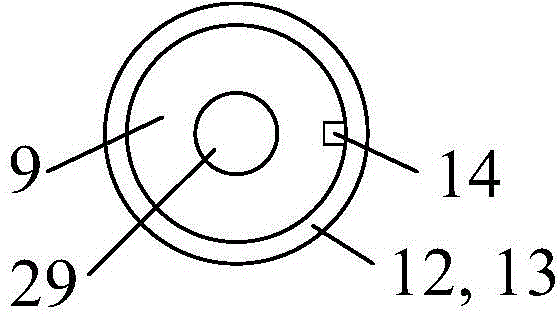

[0037] The rod body of the probe tube 1 is covered with a sealing capsule 11, the upper end of the probe tube 1 is provided with external threads, and the lower end is provided with internal threads. The boss 13 is fixed, the cross section of the upper boss 12 and the lower boss 13 is trapezoidal, and the probe tube 1 rod body at the bottom of the lower boss 13 has a groove 14; Through the ball valve 10, the electric three-way ball valve 10 includes an actuator 16, an electromagnetic coil 15, an upper port 18 and a side port 17, and the actuator 16 can rotate between the upper port 18 and the side port 17.

[0038] The drilling device comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com