In-line four-cylinder water-cooling diesel engine cylinder head cover

A diesel engine and valve chamber technology, which is applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of increasing the cost of diesel engines, poor economy, and low integration of valve chamber covers, achieving light weight, compact structure, Highly integrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

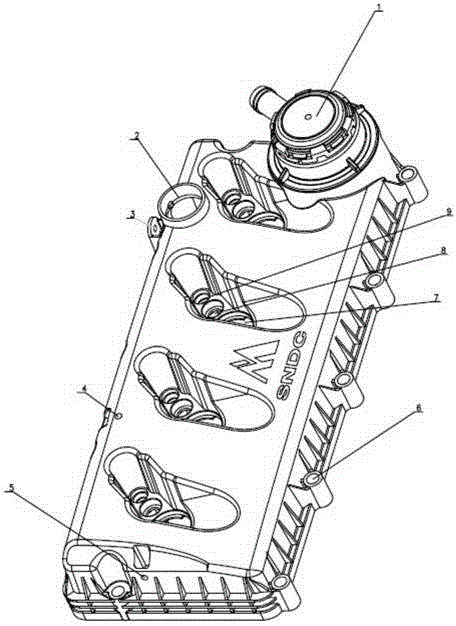

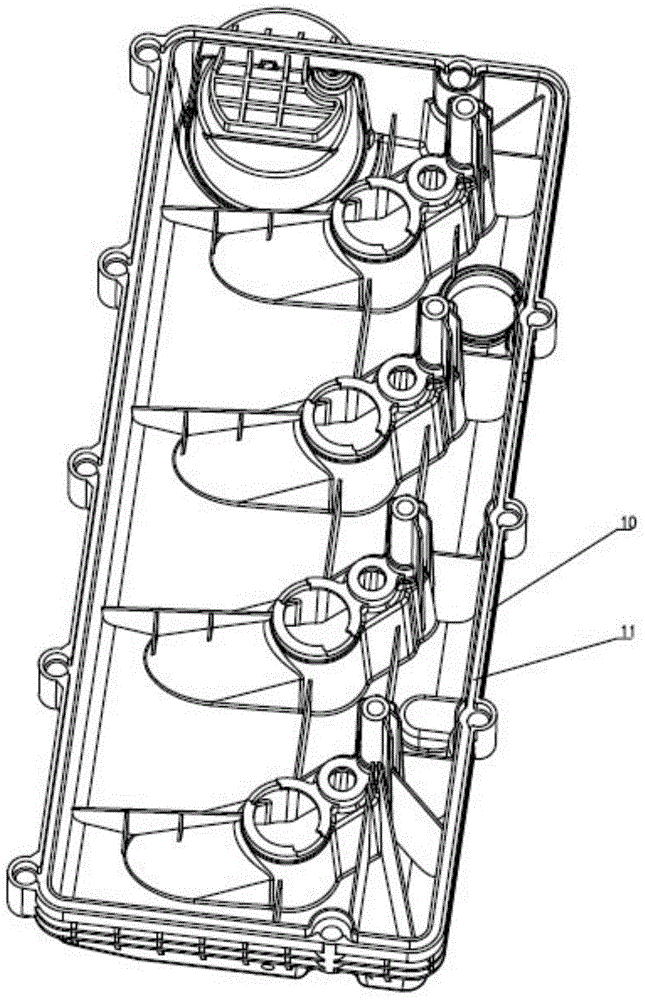

[0022] refer to figure 1 and figure 2 , a valve chamber cover for an inline four-cylinder water-cooled diesel engine, comprising an oil-water separator 1 for discharging exhaust gas in the body of the diesel engine; a fuel filler cap mounting hole 2 for installing the fuel filler cap to add engine oil to the diesel engine;

[0023] 3 mounting holes 3, 4, and 5 for the engine wire harness clips, used to fix the engine wire harness after the clips are installed;

[0024] 10 bolt mounting holes 6 for fixing the valve cover on the cylinder head;

[0025] 4 injector oil seal installation holes 7, used to install oil seals to prevent oil leakage from the injector; 4 injector pressure plate bolt oil seal installation holes 8, used to install oil sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com