A telescopic compensation structure suitable for cryogenic insulation pipes

A low-temperature thermal insulation and compensation structure technology, which is applied to expansion compensation devices, pipe components, pipes/pipe joints/pipe fittings for pipelines, etc., can solve problems such as affecting the effect of vacuuming, difficult expansion and contraction, and inspection of corrugated sections. Achieving the effect of avoiding the intractable dead angle of evacuation, good expansion and compensation ability, and simple structure production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

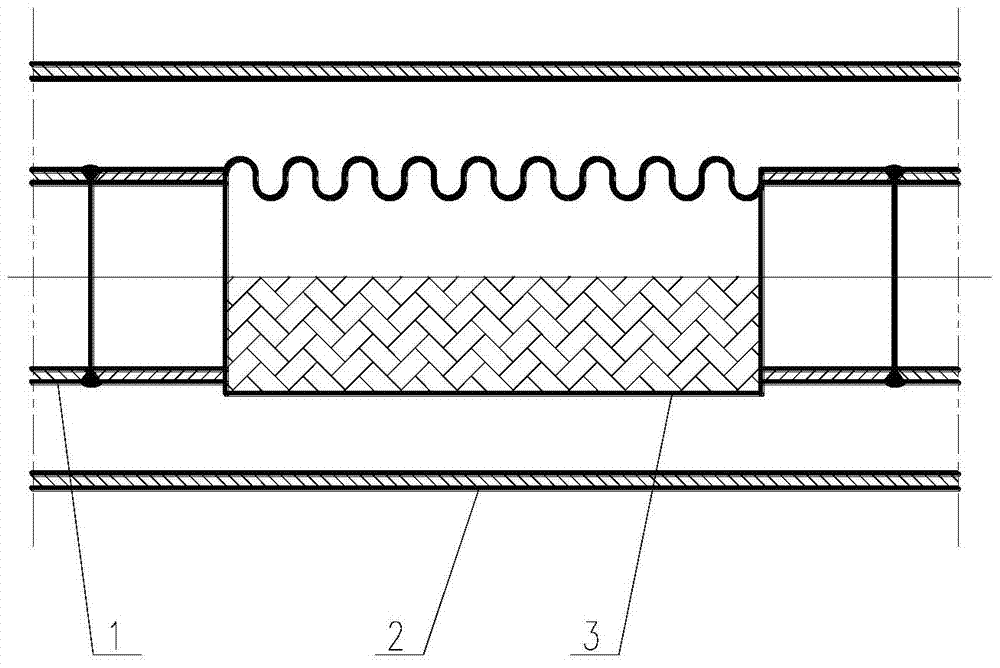

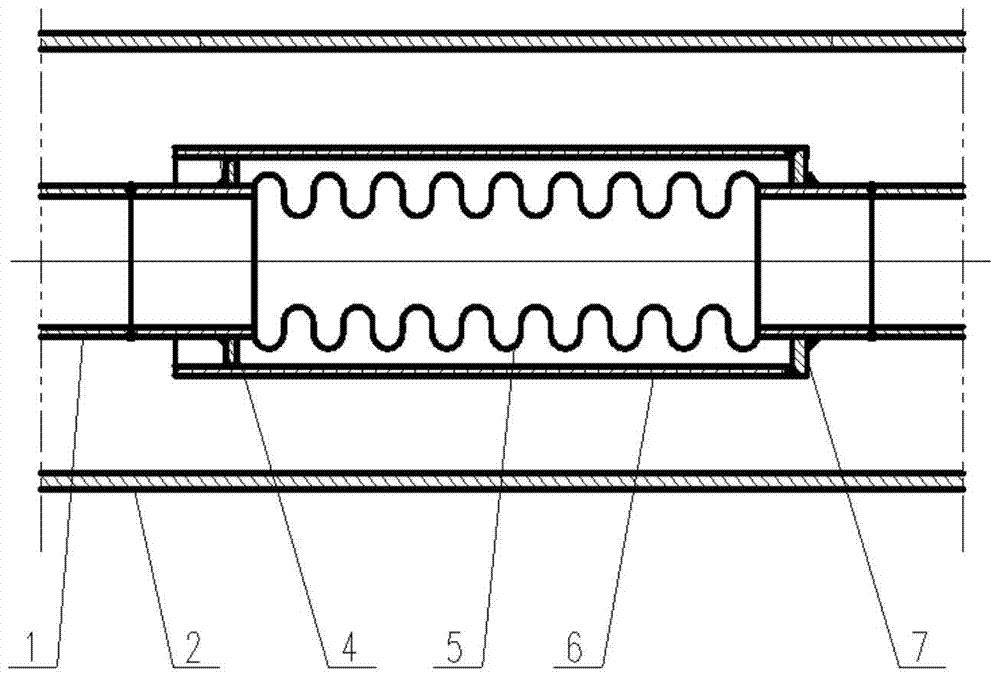

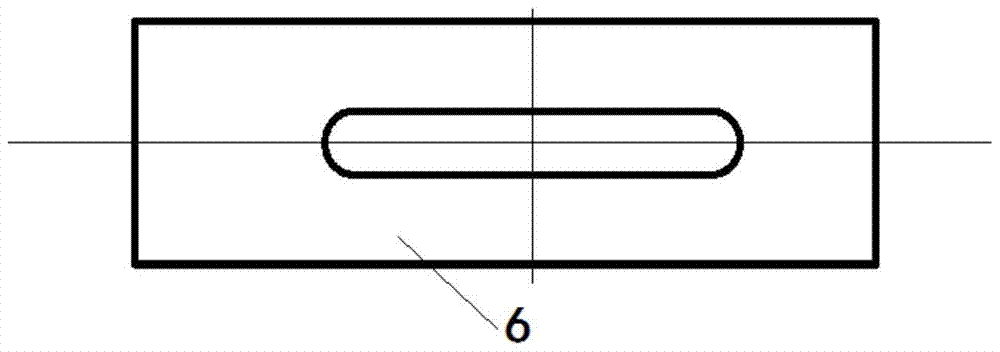

[0015] Such as figure 2 As shown, a telescopic compensation structure suitable for cryogenic insulation pipes includes a protective casing assembly arranged between the inner pipe and the outer pipe of the cryogenic insulation pipe, and the protective casing assembly includes a bellows-shaped expansion joint and a protective sleeve pipe, the expansion joint is arranged inside the protective sleeve, the expansion joint is used to connect two sections of the inner pipe and seal at the joint, the protective sleeve is arranged outside the inner pipe, the Both ends of the protection sleeve are radially provided with an annular support plate and a fixed plate to connect with the inner tube, the support plate is fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com