Pipeline system flow noise suppression device and method broadening acoustic band gaps

A pipeline system and noise suppression technology, applied in the direction of pipe components, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve problems such as performance limitations, achieve simple structure, meet low-frequency broadband noise reduction requirements, and be easy to assemble and apply Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings.

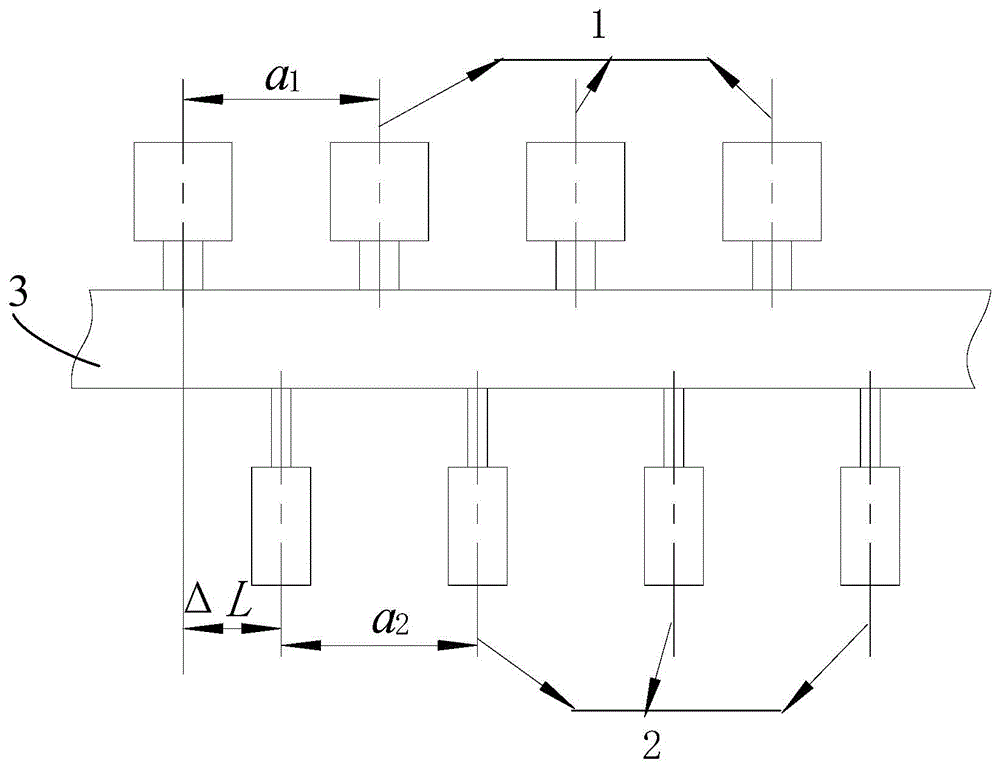

[0036] The invention provides a pipeline system flow noise suppression device for widening the acoustic band gap, the structure of which is as follows: figure 1 As shown, it includes a first muffler 1 , a second muffler 2 and a piping system 3 .

[0037] Wherein, the muffler frequency range of the first muffler 1 is lower than that of the second muffler 2 . The first muffler 1 and the second muffler 2 are placed in the piping system 3 at equidistant intervals, and the placement position of the second muffler 2 has a certain offset ΔL compared with the placement position of the first muffler 1 (such as figure 1 shown).

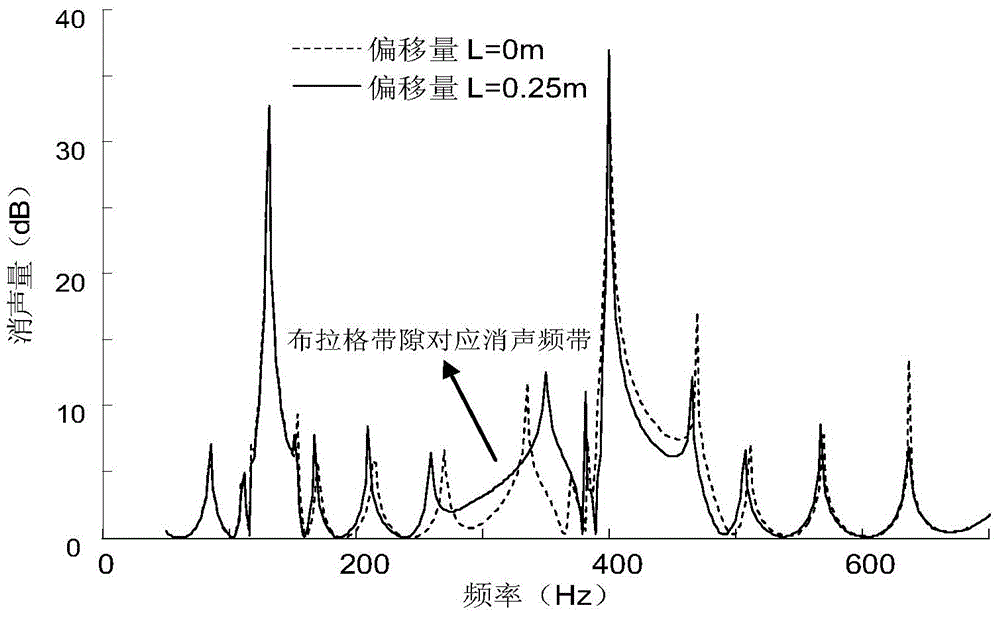

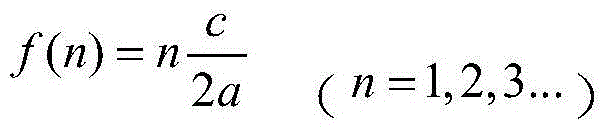

[0038] The anechoic frequency band of the first muffler 1 should be below the initial frequency of its target band gap. According to the Bragg band gap mechanism, it will form a Bragg acoustic band gap t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com