Device for preparing ice slurry by use of spiral drawknife device

A spiral scraper and ice slurry technology, which is applied in ice making, ice making, ice storage/distribution, etc., can solve the problems of hindering the heat exchange between the aqueous solution and the refrigerant, the inconvenience of making ice slurry, and the wear of the rotating scraper, and achieves structural Simple, low cost, reduce mechanical wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

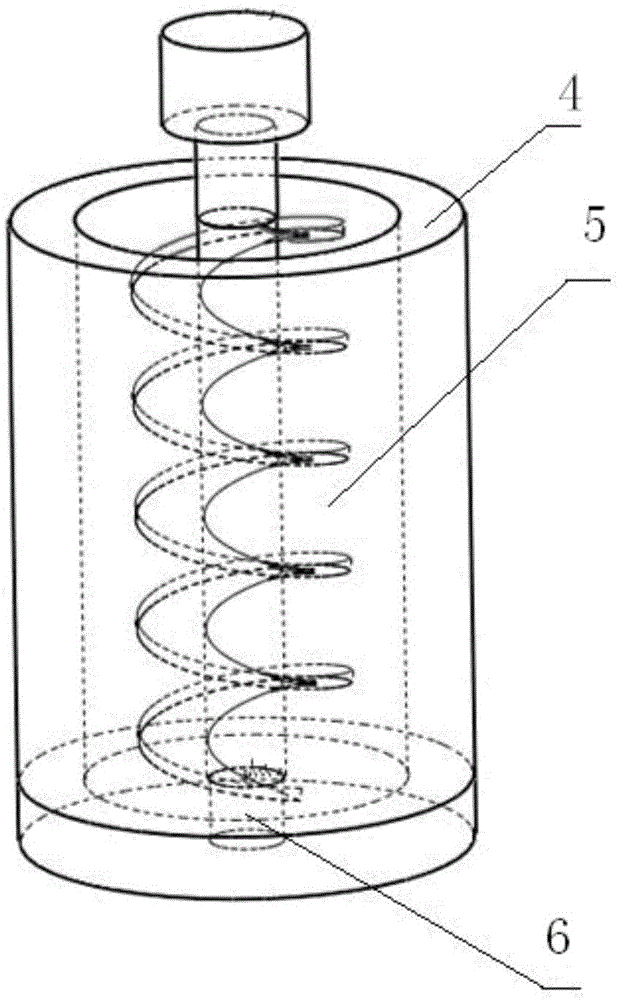

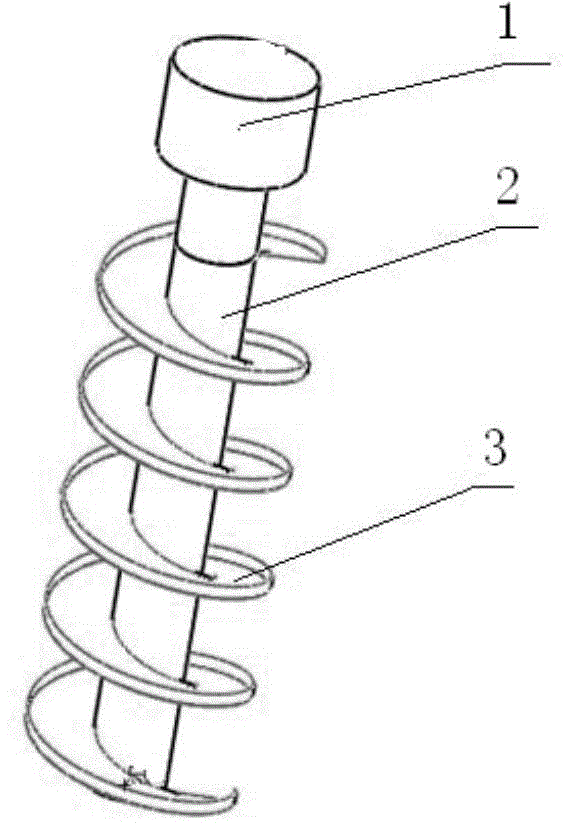

[0016] The schematic diagram of spiral scraper of the present invention making ice slurry device is as figure 1 and figure 2 As shown, it includes an ice slurry generator 5 and an ice scraping mechanism. The ice scraping mechanism includes a motor 1, a screw shaft 2 and a helical scraper 3 installed on the helical shaft 2. The helical scraper 3 is axially stretch. The spiral direction of the spiral shaft 2 and the spiral scraper 3 is to make the ice slurry solution flow to the ice outlet 6, and the motor 1 drives the spiral shaft 2 to rotate. The screw shaft 2 is installed on the axis of the ice slurry generator 5 .

[0017] In order to reduce the mechanical wear caused by direct scraping, the horizontal radius of the helical scraper 3 is slightly smaller than the inner diameter of the inner cylinder wall 4 of the ice slurry gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com