A device for preventing ice blockage in a device for preparing ice slurry by supercooling

A filter device and ice slurry technology, applied in ice making, ice making, lighting and heating equipment, etc., can solve the problems of limited effect, reduced adhesion, inability to completely suppress ice crystal formation and viscosity, and achieve reliable performance , The effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

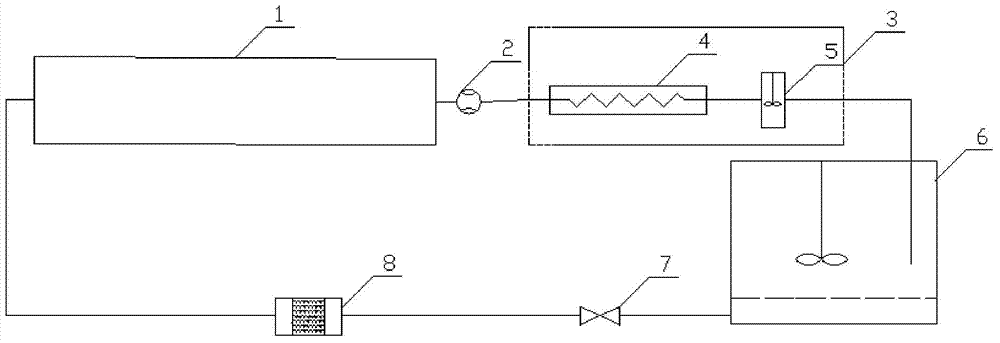

Embodiment 1

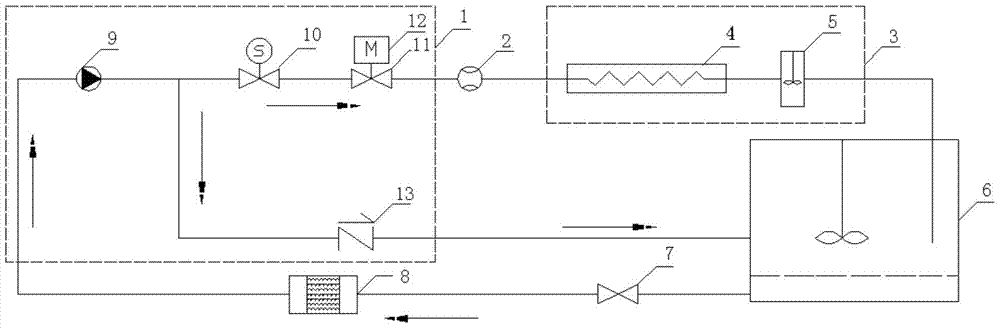

[0034] Such as figure 2 As shown, the ice slurry generating device 3 includes a subcooler 4 and a supercooling remover 5, the supercooling remover 5 is connected to the ice storage tank 6, and the ice storage tank 6 is connected to the ice crystal filtering device 8 through a stop valve 7, and the pulsation generating device 1 The structure is: the pipeline pump 9, the electromagnetic valve 10 and the leaf valve 11 are connected in series in sequence, the leaf valve 11 is connected to the frequency modulation motor 12, the inlet of the pipeline pump 9 is connected to the ice crystal filter device 8, and the outlet of the leaf valve 11 is connected to the ice crystal through the flow meter 2. The inlet of the subcooler 4 of the slurry generating device 3 is connected, the inlet of the check valve 13 is connected between the pipeline pump 9 and the solenoid valve 10 , and the outlet of the check valve 13 is connected with the ice storage tank 6 . The pulsation amplitude and fre...

Embodiment 2

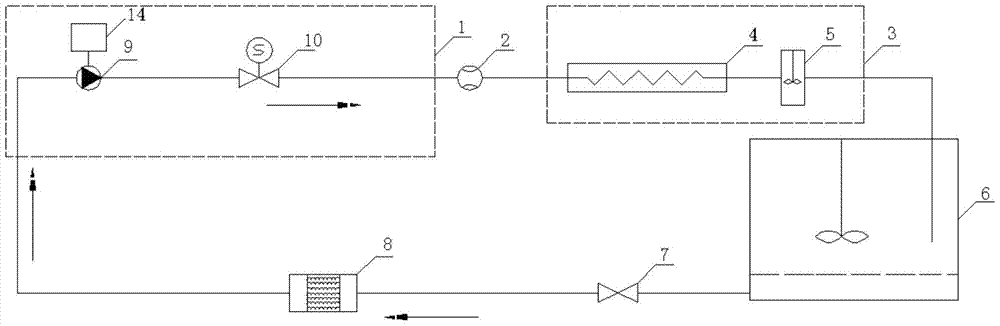

[0040] Such as image 3 As shown, the supercooling ice slurry production device prevents ice blockage by strengthening fluid pulsation. The ice slurry generating device 3 includes a subcooler 4 and a supercooling remover 5. The supercooling remover 5 is connected to the ice storage tank 6, and the ice storage Tank 6 is connected to ice crystal filtering device 8 through stop valve 7. The structure of pulsation generating device 1 is: pipeline pump 9 and solenoid valve 10 are connected in series in sequence, pipeline pump 9 is connected to frequency conversion device 14, and the inlet of pipeline pump 9 is connected to ice crystal filtering device 8. , the outlet of the solenoid valve 10 is connected to the inlet of the subcooler 4 of the ice slurry generating device 3 through the flow meter 2 . By adjusting the pulsation device, the fluid pulsation amplitude and frequency in the pipeline can be adjusted, and the fluid flow direction is as follows: image 3 indicated by the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com